At its core, a PTFE seal's temperature capability is determined by three primary factors: the specific filler material blended with the base PTFE, the physical seal geometry, and the media compatibility of the chemical environment it operates in. These elements work together to define the seal's ultimate performance under thermal stress.

The theoretical temperature rating of a PTFE material is only a starting point. A seal's true operational temperature limit is a dynamic property defined by the interplay between the seal's material composition, its physical design, and the specific pressures and speeds of its application.

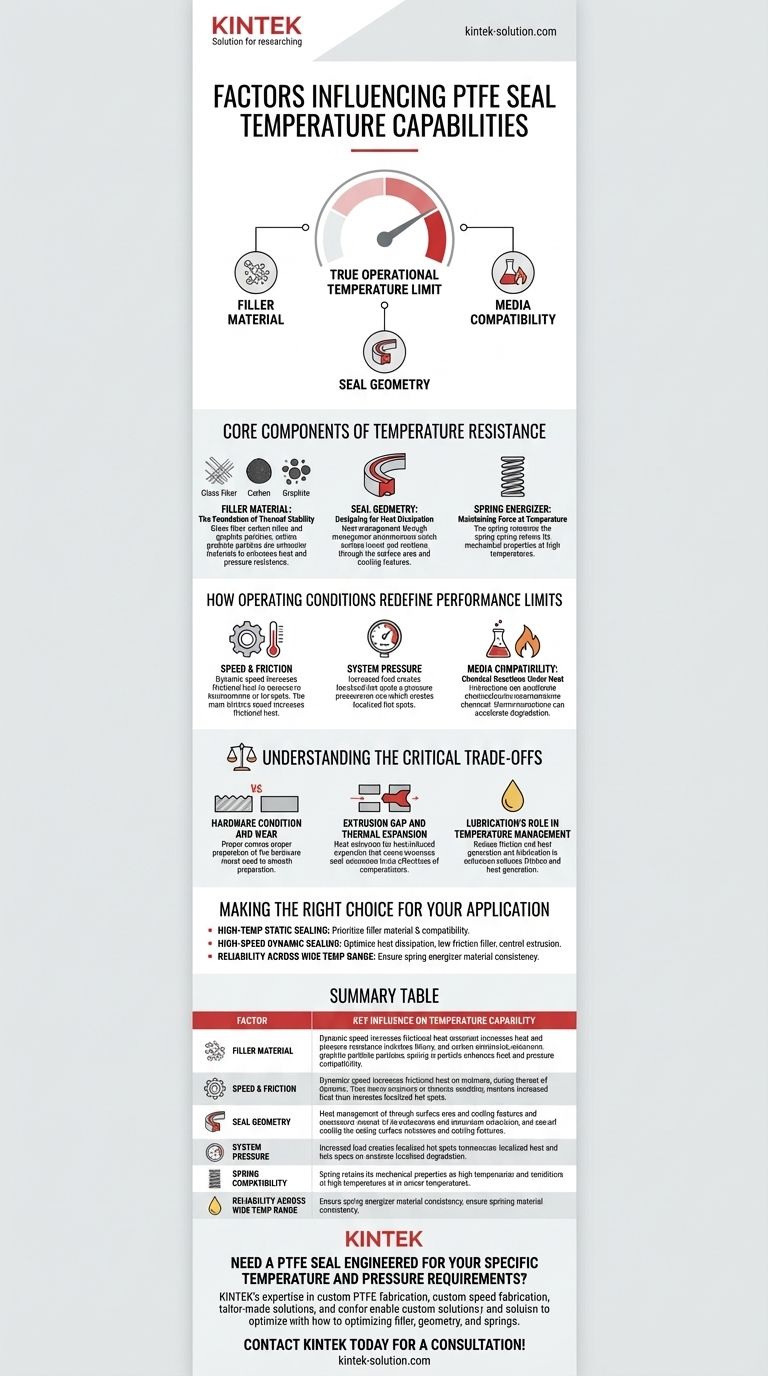

The Core Components of Temperature Resistance

Understanding a seal's intrinsic properties is the first step. The material and design create a baseline for thermal performance before any external factors are introduced.

Filler Material: The Foundation of Thermal Stability

Virgin PTFE has a relatively limited temperature range. The addition of fillers is critical for enhancing its resistance to heat and pressure.

Common high-temperature fillers include glass fiber, carbon, and graphite. Each additive modifies the base polymer's characteristics, improving wear resistance and thermal stability, which is essential for maintaining seal integrity at elevated temperatures.

Seal Geometry: Designing for Heat Dissipation

The physical shape of the seal jacket plays a significant role in managing heat. A well-designed geometry can help dissipate the frictional heat generated during dynamic operation.

Designs with more surface area or features that promote cooling can extend the seal's life and effective temperature range, preventing premature failure from overheating.

Spring Energizer: Maintaining Force at Temperature

The internal spring energizer provides the consistent force needed for the seal lip to maintain contact with the hardware.

This spring must be made from a material that retains its mechanical properties (its "springiness") at the target operating temperature. If the spring weakens due to heat, the seal will lose its force and fail to seal effectively.

How Operating Conditions Redefine Performance Limits

A seal does not exist in a vacuum. The application's environment can drastically alter its real-world temperature capabilities, often being the deciding factor in its success or failure.

The Impact of Speed and Friction

In dynamic applications, higher rotational or linear speeds directly increase friction at the sealing point. This friction generates significant heat.

This generated heat can easily push the seal beyond its material limits, even if the system's ambient temperature is well within range. Managing speed is critical for managing temperature.

The Role of System Pressure

Higher system pressures increase the load on the seal lip, which in turn increases friction and can create localized hot spots.

This effect is especially pronounced in dynamic sealing, where the combination of high pressure and high speed can quickly lead to thermal degradation and accelerated wear.

Media Compatibility: Chemical Reactions Under Heat

The fluid or gas being sealed can interact with the PTFE jacket. At elevated temperatures, chemical reactions can accelerate, potentially degrading the seal material and compromising its thermal stability.

It is crucial to verify that the chosen seal compound is compatible with the system media not just at room temperature, but across the entire expected operational temperature range.

Understanding the Critical Trade-offs

Selecting a seal for a high-temperature application is a balancing act. Improving one performance characteristic can often compromise another.

Hardware Condition and Wear

High-temperature PTFE compounds are often harder due to their fillers. This can increase wear on the hardware surface, especially if the surface finish or hardness is not properly specified.

Proper hardware preparation is non-negotiable. A smooth, hard mating surface is essential to prevent abrasion and ensure a long service life for both the seal and the equipment.

Extrusion Gap and Thermal Expansion

All materials expand when heated. At high temperatures, the PTFE seal will soften and expand.

If the extrusion gap (the clearance between the moving and stationary hardware) is too large, the softened seal material can be pushed into this gap by system pressure, causing damage and rapid failure.

Lubrication's Role in Temperature Management

Proper lubrication is one of the most effective tools for managing heat. It reduces the coefficient of friction between the seal and the hardware, directly lowering the amount of heat generated.

Even in applications considered "dry-running," trace amounts of system media can provide a lubricating film that significantly impacts seal temperature and lifespan.

Making the Right Choice for Your Application

Your final selection should be based on a holistic view of the system, not just a single temperature rating on a datasheet.

- If your primary focus is high-temperature static sealing: Prioritize the filler material and its chemical compatibility with your system media.

- If your primary focus is high-speed dynamic sealing: Emphasize a design that optimizes heat dissipation, uses a low-friction filler, and carefully controls the hardware's extrusion gap.

- If your primary focus is reliability across a wide temperature range: Pay close attention to the spring energizer material to ensure it maintains consistent force from cold start-up to peak operating heat.

Ultimately, successful seal performance depends on understanding that temperature resistance is a property of the entire system, not just the component.

Summary Table:

| Factor | Key Influence on Temperature Capability |

|---|---|

| Filler Material | Enhances base PTFE's thermal stability and wear resistance (e.g., glass, carbon). |

| Seal Geometry | Affects heat dissipation; designs with more surface area can better manage frictional heat. |

| Spring Energizer | Must retain mechanical properties (spring force) at the target operating temperature. |

| Speed & Friction | Higher speeds generate more frictional heat, potentially exceeding material limits. |

| System Pressure | Increases load and friction, creating localized hot spots and accelerating wear. |

| Media Compatibility | Chemical reactions with the sealed fluid/gas can accelerate and degrade the seal at high temperatures. |

Need a PTFE Seal Engineered for Your Specific Temperature and Pressure Requirements?

At KINTEK, we understand that a seal's performance is defined by its entire system. We don't just supply components; we deliver solutions. Our expertise in custom PTFE fabrication allows us to tailor seals, liners, and labware to your exact needs—optimizing filler materials, geometry, and spring energizers for superior performance in high-temperature semiconductor, medical, laboratory, and industrial applications.

We prioritize precision production while offering custom fabrication from prototypes to high-volume orders.

Let our engineers help you solve your toughest sealing challenges. Contact KINTEB today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do PTFE lined check valves differ from traditional swing check valves? A Guide to Superior Flow Control

- Why is CNC machining suitable for custom Teflon parts? Achieve Precision for Demanding Applications

- What are the advantages of using PTFE as the material for rotary shaft lip seals? Achieve Unmatched Reliability in Extreme Conditions

- How does the fiber structure of ePTFE gaskets provide mechanical compensation? Sealing Imperfect Flanges

- How can anti-stick coatings benefit PTFE gasket maintenance? Reduce Downtime and Protect Equipment

- What is the basic structure and working principle of PTFE O-ring seals? Unlock Superior Sealing Performance

- Why does the spring PTFE sealing ring maintain effective sealing across its working pressure range? Discover the Engineering Secret

- What machining processes are used to create Teflon parts? Achieve Precision with Expert PTFE Machining