In the automotive industry, Polytetrafluoroethylene (PTFE) is a critical material used to enhance vehicle reliability, efficiency, and longevity. It is engineered into essential components like seals, gaskets, and hose linings that must withstand aggressive chemicals, extreme temperatures, and constant friction. Its unique properties solve many of the most demanding challenges found in fuel systems, engines, transmissions, and suspension.

The core reason PTFE is so prevalent in automotive design is its unique combination of three properties: it is nearly inert to corrosive vehicle fluids, it remains stable at high engine temperatures, and its extremely low friction coefficient reduces wear and improves efficiency.

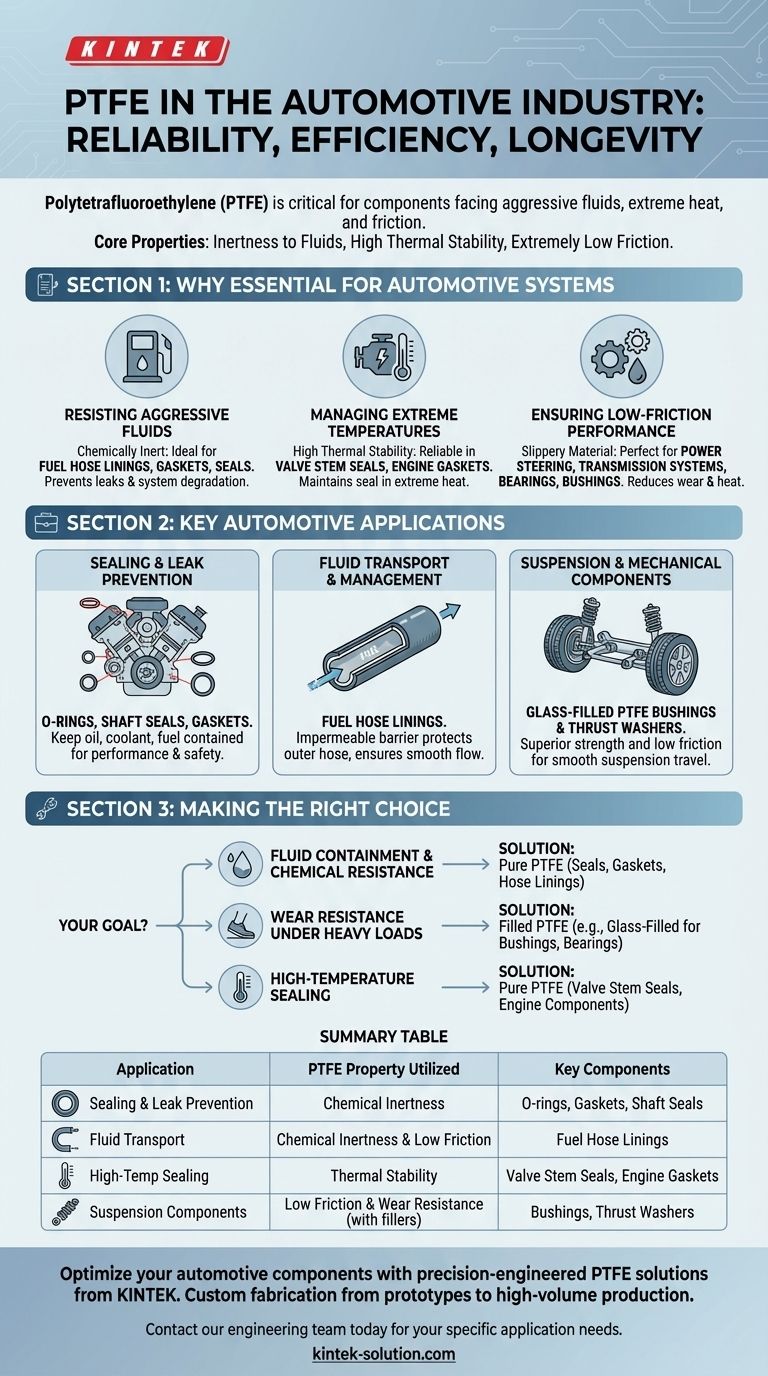

Why PTFE is Essential for Automotive Systems

PTFE is not just a single-use material; it is a versatile problem-solver chosen by engineers for its ability to perform under the harsh conditions inherent in vehicle operation. Its value comes from a combination of thermal, chemical, and mechanical properties that outperform many traditional materials.

Resisting Aggressive Fluids and Chemicals

Modern vehicles rely on a range of aggressive fluids, including fuel, engine oil, transmission fluid, and lubricants. These substances can degrade conventional rubber and plastic components over time.

PTFE is chemically inert, meaning it does not react with these corrosive fluids. This makes it the ideal material for fuel hose linings, gaskets, and seals, preventing leaks and ensuring the integrity of the entire fluid system.

Managing Extreme Temperatures

The engine bay is a high-temperature environment where many materials would fail. Components near the engine block or exhaust system must maintain their shape and function without degrading.

PTFE has a very high melting point and excellent thermal stability. This allows it to be used for critical parts like valve stem seals and other engine gaskets, providing a reliable seal even under extreme heat.

Ensuring Low-Friction Performance

Friction creates wear, reduces efficiency, and generates unwanted heat. In systems with moving parts, minimizing friction is a primary engineering goal.

As one of the most slippery materials known, PTFE is perfect for reducing friction. It is used in power steering and transmission systems to ensure smooth operation and is also a key component in low-wear bearings and bushings.

Key Automotive Applications

PTFE's properties translate directly into specific, high-value applications that are crucial for a vehicle's performance and durability.

Sealing and Leak Prevention

The most common use of PTFE is to prevent leaks. It is fabricated into O-rings, shaft seals, and gaskets that are placed between mating parts throughout the engine and drivetrain.

These components ensure that oil, coolant, and fuel stay where they belong, which is fundamental to engine performance, safety, and environmental compliance.

Fluid Transport and Management

PTFE is frequently used as a liner inside hoses that transport fuel or hydraulic fluids. This lining creates an impermeable, non-reactive barrier.

This protects the outer hose material from chemical attack while its low-friction surface ensures the smooth and efficient flow of the fluid within the system.

Suspension and Mechanical Components

For components that bear heavy loads and require low friction, standard PTFE is often enhanced with fillers like glass fiber.

This glass-filled PTFE is used for suspension components like bushings and thrust washers. The glass provides superior mechanical strength and wear resistance, while the PTFE provides the low-friction surface needed for smooth suspension travel.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. Engineers must consider its limitations and specify the correct grade for the application.

Mechanical Strength Limitations

In its pure form, PTFE is a relatively soft material. Under continuous pressure or heavy loads, it can be susceptible to "creep," where the material slowly deforms over time.

This makes pure PTFE unsuitable for high-load structural applications without reinforcement.

The Critical Role of Fillers

To overcome its mechanical weaknesses, PTFE is often blended with fillers like glass, carbon, or bronze. These fillers dramatically increase the material's rigidity, wear resistance, and ability to handle heavy loads.

This is why you see "glass-filled PTFE" specified for demanding mechanical parts like suspension bushings, combining the strength of glass with the low friction of PTFE.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the specific challenge you need to solve.

- If your primary focus is fluid containment and chemical resistance: Pure PTFE is the ideal choice for seals, gaskets, and hose linings in contact with fuel, oil, or transmission fluid.

- If your primary focus is wear resistance under heavy loads: A filled grade, such as glass-filled PTFE, should be specified for suspension bushings, bearings, and thrust washers.

- If your primary focus is high-temperature sealing: PTFE is a reliable choice for critical engine components like valve stem seals, where other elastomers would quickly degrade.

Ultimately, PTFE's strategic application is a key reason modern vehicles can operate so reliably under such demanding conditions.

Summary Table:

| Application | PTFE Property Utilized | Key Components |

|---|---|---|

| Sealing & Leak Prevention | Chemical Inertness | O-rings, Gaskets, Shaft Seals |

| Fluid Transport | Chemical Inertness & Low Friction | Fuel Hose Linings |

| High-Temperature Sealing | Thermal Stability | Valve Stem Seals, Engine Gaskets |

| Suspension Components | Low Friction & Wear Resistance (with fillers) | Bushings, Thrust Washers |

Optimize your automotive components with precision-engineered PTFE solutions from KINTEK.

Whether you require chemically inert seals for fuel systems, high-temperature gaskets for engine blocks, or durable, low-friction bushings for suspension systems, KINTEK has the expertise and manufacturing capability to deliver. We specialize in custom PTFE fabrication—from prototypes to high-volume production—for the semiconductor, medical, laboratory, and industrial sectors, ensuring your components meet the highest standards of performance and durability.

Contact our engineering team today to discuss your specific application needs and receive a custom quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts