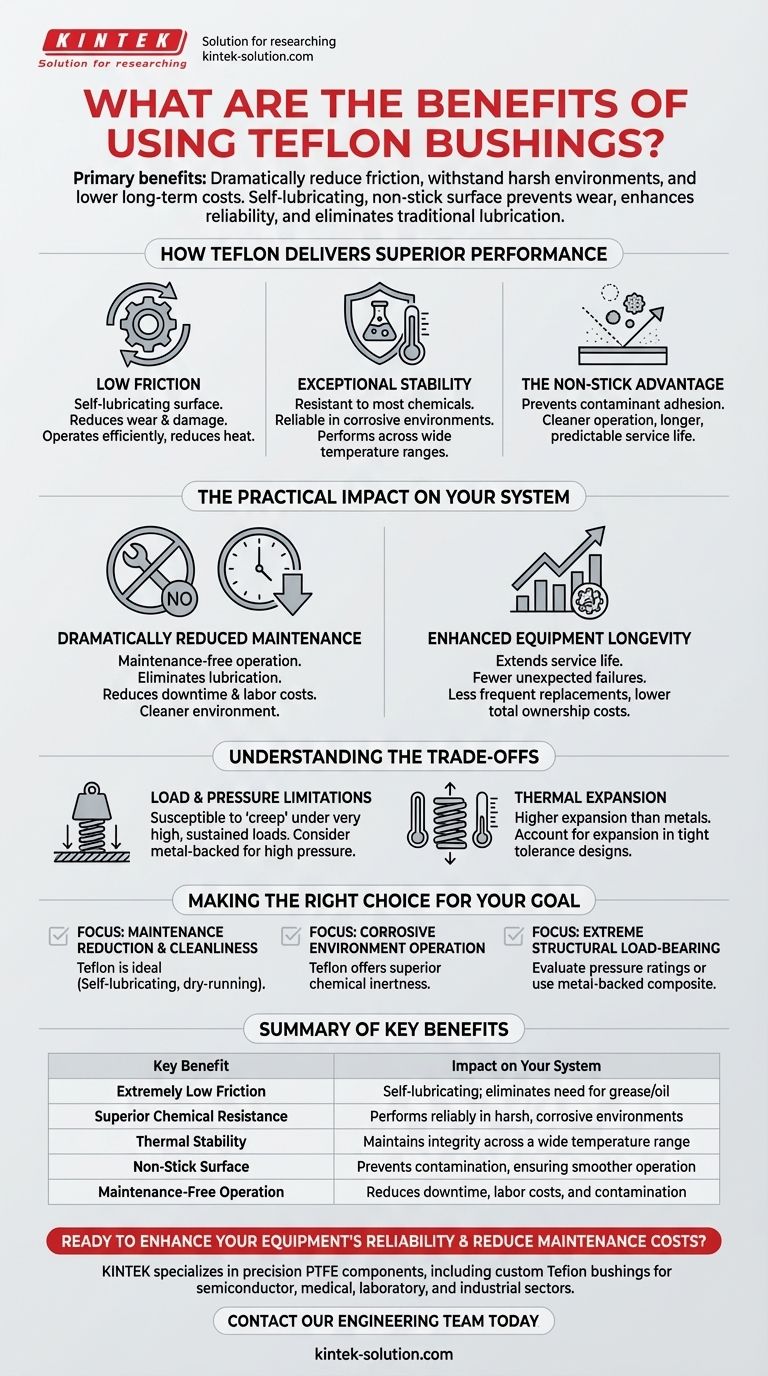

The primary benefits of using Teflon bushings are their ability to dramatically reduce friction, withstand harsh environments, and lower long-term costs. By creating a self-lubricating, non-stick surface, they prevent wear on moving parts, enhance equipment reliability, and eliminate the need for traditional oil or grease lubrication.

The core advantage of Teflon isn't just one feature, but how its unique chemical properties work together. This creates a maintenance-free component that simplifies mechanical design, reduces downtime, and improves the overall efficiency of any system it's placed in.

How Teflon Delivers Superior Performance

To understand the benefits, we must first look at the inherent properties of Polytetrafluoroethylene (PTFE), the material commonly known as Teflon. These characteristics are the foundation of its performance as a bushing material.

The Power of Low Friction

A Teflon bushing’s defining feature is its extremely low coefficient of friction. This allows it to function as a "self-lubricating" surface.

Parts move smoothly against the bushing without the need for external lubricants like oil or grease. This directly reduces wear and surface damage on critical components.

Because there is less resistance, systems can operate more efficiently, reducing heat buildup, especially under high loads or high sliding velocities.

Exceptional Chemical and Thermal Stability

Teflon is a highly inert material, making it resistant to almost all chemicals. This allows Teflon bushings to perform reliably in corrosive environments where metal bushings would degrade.

It also maintains its integrity across a wide range of temperatures, providing crucial thermal stability for equipment that operates in fluctuating or high-heat conditions.

The Non-Stick Advantage

Teflon’s famous non-stick surface is a significant benefit for bushings. This property prevents contaminants, dust, and other debris from adhering to the component.

A cleaner bushing surface means smoother operation and a longer, more predictable service life, as abrasive particles are less likely to become embedded and cause damage.

The Practical Impact on Your System

These material properties translate directly into tangible, operational advantages that improve both performance and your bottom line.

Dramatically Reduced Maintenance

The most significant impact is the move to a maintenance-free operation. Because Teflon bushings operate dry, you eliminate the entire process of scheduling and applying lubrication.

This reduces system downtime, lowers labor costs, and creates a cleaner operating environment free from oil and grease contamination.

Enhanced Equipment Longevity

By minimizing friction and preventing wear between moving parts, Teflon bushings directly extend the service life of your equipment.

This increased reliability means fewer unexpected failures and less frequent need for component replacements, contributing to lower overall ownership costs.

Understanding the Trade-offs

While highly effective, Teflon bushings are not a universal solution. An objective assessment requires understanding their limitations compared to traditional metal or composite bushings.

Load and Pressure Limitations

Standard Teflon is a relatively soft material. Under very high, sustained loads, it can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. For extremely high-pressure applications, a metal-backed or composite PTFE bushing may be necessary.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than most metals. In designs with very tight tolerances, engineers must account for how the bushing will expand or contract with temperature changes to avoid binding.

Making the Right Choice for Your Goal

Selecting the correct bushing requires aligning the material's strengths with your primary engineering objective.

- If your primary focus is maintenance reduction and cleanliness: Teflon is an ideal choice due to its self-lubricating, dry-running properties.

- If your primary focus is operation in a corrosive environment: Teflon's superior chemical inertness offers a significant advantage over most metal alternatives.

- If your primary focus is extreme structural load-bearing: Carefully evaluate the pressure ratings to ensure standard Teflon meets your needs, or consider a metal-backed composite.

By understanding these core principles, you can confidently determine where a Teflon bushing is the optimal engineering choice.

Summary Table:

| Key Benefit | Impact on Your System |

|---|---|

| Extremely Low Friction | Self-lubricating; eliminates need for grease/oil |

| Superior Chemical Resistance | Performs reliably in harsh, corrosive environments |

| Thermal Stability | Maintains integrity across a wide temperature range |

| Non-Stick Surface | Prevents contamination, ensuring smoother operation |

| Maintenance-Free Operation | Reduces downtime, labor costs, and contamination |

Ready to enhance your equipment's reliability and reduce maintenance costs?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom Teflon bushings. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures you get a component perfectly suited to your application's demands.

Contact our engineering team today to discuss your specific requirements and discover how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability