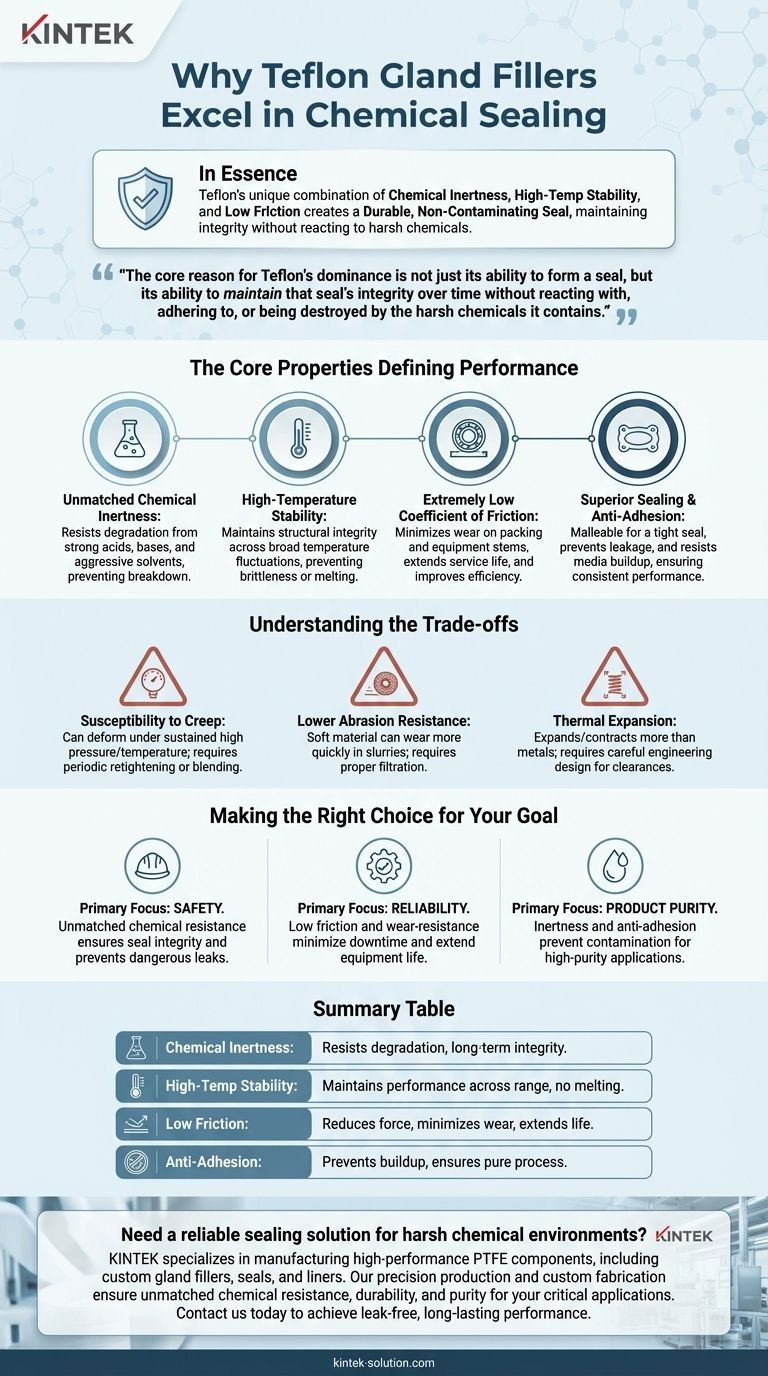

In essence, Teflon gland fillers are uniquely effective for chemical industry sealing because of their near-total chemical inertness, high-temperature stability, and extremely low friction. This combination allows them to create a durable, non-contaminating seal that will not degrade when exposed to the most aggressive acids, bases, and solvents, ensuring both safety and process integrity where other materials would quickly fail.

The core reason for Teflon's dominance is not just its ability to form a seal, but its ability to maintain that seal's integrity over time without reacting with, adhering to, or being destroyed by the harsh chemicals it contains.

The Core Properties Defining Teflon's Performance

Teflon, or Polytetrafluoroethylene (PTFE), is not just one good material among many; its fundamental properties make it almost purpose-built for the challenges of the chemical industry.

Unmatched Chemical Inertness

Teflon is renowned for being one of the most non-reactive substances known. It resists degradation from a vast range of strong acids, bases, and aggressive chemical solvents.

This means the gland filler itself will not break down, swell, or weaken when in contact with process fluids like sulfuric acid or hydrofluoric acid. This chemical stability is the primary reason it can be trusted in such a wide array of applications.

High-Temperature Stability

Chemical processes often involve significant temperature fluctuations. Teflon gland fillers maintain their structural integrity and sealing properties across a broad temperature range.

This stability prevents the seal from becoming brittle at low temperatures or melting and extruding at high temperatures, which are common failure points for lesser materials.

Extremely Low Coefficient of Friction

Teflon has one of the lowest friction coefficients of any solid, giving it a distinct "non-stick" quality. In a gland filler application, this is critical for two reasons.

First, it reduces the force needed to actuate a valve or the drag on a rotating pump shaft, improving operational efficiency. Second, it minimizes wear on both the packing material and the equipment stem or shaft, dramatically extending the service life of the entire assembly.

Superior Sealing and Anti-Adhesion

The material is malleable enough to conform to the gland and shaft, creating an exceptionally tight seal that prevents liquid or gas leakage.

Simultaneously, its anti-adhesion properties prevent process media from building up on the seal surface. This stops the seal from becoming fouled or stuck, ensuring consistent performance and preventing contamination.

Understanding the Trade-offs

While Teflon's properties are exceptional, no material is without limitations. Acknowledging these is key to proper application and engineering.

Susceptibility to Creep

Under sustained high pressure and temperature, pure Teflon can be subject to "creep" or "cold flow," where the material slowly deforms over time.

This can lead to a gradual loss of sealing pressure. For this reason, gland nuts may require periodic retightening, or fillers may be blended with other materials like carbon or glass to improve creep resistance.

Lower Abrasion Resistance

Compared to harder materials, Teflon is relatively soft. In applications with abrasive slurries or significant particulate matter, the filler can wear more quickly.

Proper system filtration and design are necessary to mitigate this potential issue and prevent premature seal failure.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. This means it expands and contracts more significantly with temperature changes.

Engineers must account for this during design to ensure that clearances are appropriate and that the seal remains effective across the full operational temperature range.

Making the Right Choice for Your Goal

Teflon's unique combination of properties makes it the superior choice for a variety of critical objectives within the chemical industry.

- If your primary focus is safety with hazardous chemicals: Teflon's unmatched chemical resistance ensures seal integrity and prevents dangerous leaks of corrosive or toxic substances.

- If your primary focus is operational reliability: Its low-friction and wear-resistant nature minimizes maintenance downtime and extends the life of critical equipment like pumps and valves.

- If your primary focus is product purity: Teflon's inertness and anti-adhesion qualities prevent the seal from contaminating the process fluid, making it ideal for food-grade or high-purity applications.

Ultimately, Teflon's effectiveness stems from its ability to solve the core challenge of chemical sealing: containing aggressive media without failing or becoming part of the problem itself.

Summary Table:

| Key Property | Benefit for Chemical Sealing |

|---|---|

| Chemical Inertness | Resists degradation from acids, bases, and solvents, ensuring long-term seal integrity. |

| High-Temperature Stability | Maintains performance across a broad temperature range without brittleness or melting. |

| Low Friction | Reduces operational force, minimizes wear on equipment, and extends service life. |

| Anti-Adhesion | Prevents media buildup and contamination, ensuring consistent, pure process flow. |

Need a reliable sealing solution for harsh chemical environments?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gland fillers, seals, and liners designed for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal that delivers unmatched chemical resistance, durability, and purity for your critical applications.

Contact us today to discuss your specific requirements and let our experts help you achieve leak-free, long-lasting performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components