In short, fillers are added to structured PTFE to fundamentally enhance its mechanical and thermal properties. Pure PTFE is relatively soft and prone to deforming, but the addition of fillers like glass, carbon, or silica transforms it into a robust material with drastically improved strength, resistance to wear, and ability to withstand deformation under load.

While pure PTFE is valued for its extreme chemical resistance and low friction, it is often too mechanically weak for demanding industrial applications. Fillers act as a structural backbone, converting PTFE into a high-performance engineering material tailored for specific challenges.

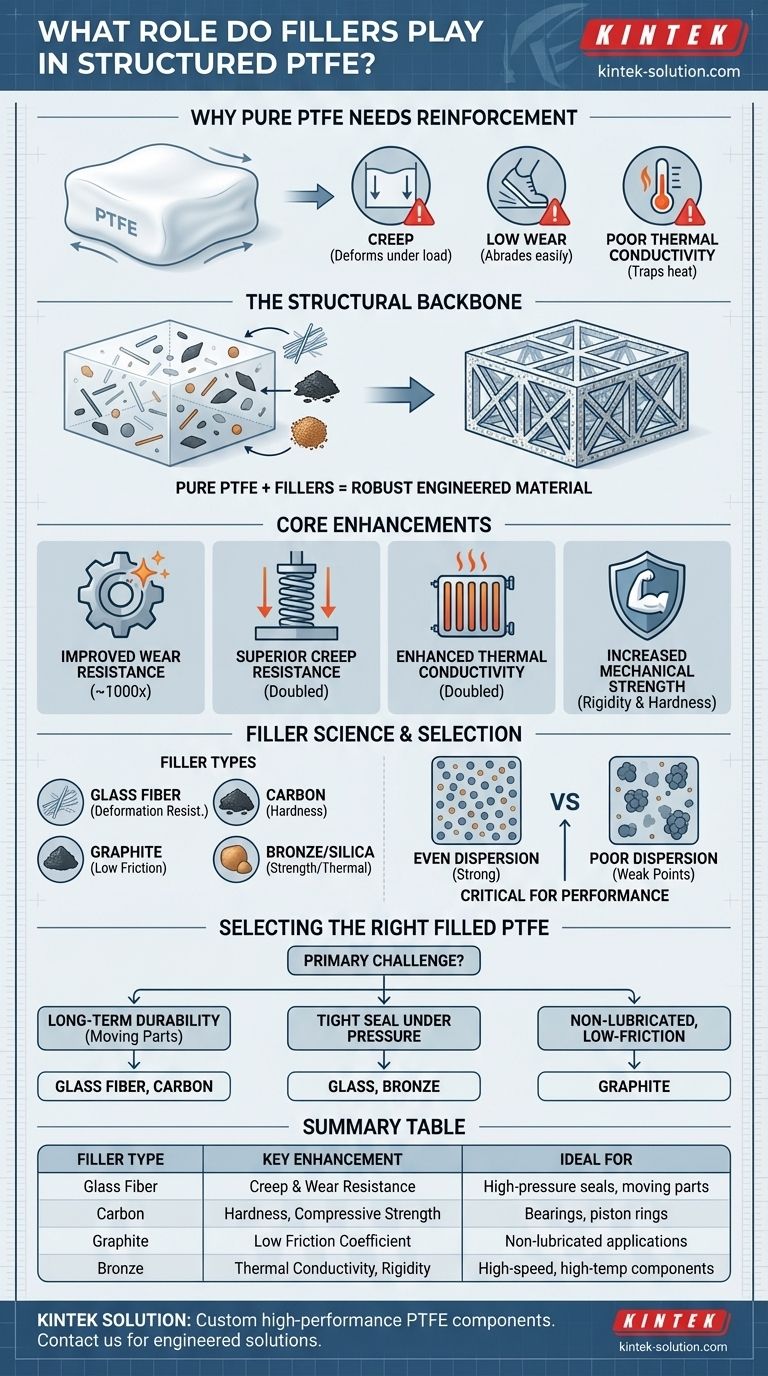

Why Pure PTFE Needs Reinforcement

To understand the role of fillers, we must first recognize the inherent limitations of unfilled, or "virgin," PTFE. While an exceptional material in many ways, its mechanical properties create significant challenges in certain applications.

The Problem of "Creep"

Pure PTFE has a tendency to "creep," meaning it slowly deforms over time when subjected to a constant load, especially at elevated temperatures. This makes it unreliable for components like high-pressure seals that must maintain their exact shape.

Low Wear and Abrasion Resistance

In dynamic applications involving friction, such as bearings or piston rings, pure PTFE wears down quickly. Its softness makes it susceptible to abrasion, leading to a shorter service life for the component.

Poor Thermal Conductivity

PTFE is a thermal insulator, meaning it does not dissipate heat well. In high-speed applications, friction generates heat that can become trapped, potentially causing the component to fail.

The Core Enhancements Provided by Fillers

Adding fillers addresses these weaknesses directly, creating a composite material with a new set of targeted properties. Research shows these enhancements can be dramatic.

Drastically Improved Wear Resistance

Filled PTFE can offer approximately 1000 times the abrasion resistance of its unfilled counterpart. This makes it vastly superior for components that experience continuous movement and friction.

Superior Creep Resistance

Fillers can double the creep resistance of PTFE. This reinforcement allows the material to hold its shape under sustained pressure, which is critical for creating reliable, long-lasting seals and gaskets.

Enhanced Thermal Conductivity

The right fillers can double the thermal conductivity of the material. This allows heat generated from friction to dissipate more effectively, enabling the component to operate at higher speeds and temperatures without failing.

Increased Mechanical Strength

Fillers like glass fiber, carbon, and bronze add significant rigidity and hardness. This improves the material's overall strength and its ability to resist deformation under direct force.

Understanding the Trade-offs

The process of creating filled PTFE is not merely about adding reinforcement; it is a precise science where the choice of filler and its integration into the PTFE matrix are critical.

Filler Type Determines the Final Properties

The specific filler used is chosen to target a desired outcome.

- Glass fiber is excellent for improving resistance to deformation.

- Carbon significantly enhances hardness and compressive strength.

- Graphite is used to create an extremely low coefficient of friction for non-lubricated applications.

- Barium sulfate and silica are common choices for adding general strength.

The Critical Role of Filler Dispersion

Simply mixing in a filler is not enough. The particles, such as hollow glass spheres or silica, must be dispersed evenly throughout the PTFE matrix. Poor dispersion can create weak points, compromising the balance between mechanical strength and sealing tightness.

Selecting the Right Filled PTFE for Your Application

The choice of a filled PTFE is entirely dependent on the primary challenge you need to solve.

- If your primary focus is long-term durability in moving parts: You need a filler that maximizes wear and abrasion resistance, such as glass fiber or carbon.

- If your primary focus is maintaining a tight seal under high pressure: A filler that enhances creep resistance, like glass or bronze, is the correct choice to prevent deformation.

- If your primary focus is non-lubricated, low-friction performance: A graphite-filled compound will provide the lowest friction for smooth operation.

Ultimately, fillers elevate PTFE from a simple polymer to a versatile family of engineered materials designed to solve specific challenges.

Summary Table:

| Filler Type | Key Enhancement | Ideal For |

|---|---|---|

| Glass Fiber | Improves creep resistance, wear resistance | High-pressure seals, durable moving parts |

| Carbon | Increases hardness, compressive strength | Bearings, piston rings |

| Graphite | Lowers friction coefficient | Non-lubricated applications |

| Bronze | Enhances thermal conductivity, rigidity | High-speed, high-temperature components |

Need a custom PTFE component that outperforms standard materials? At KINTEK, we specialize in manufacturing high-performance filled PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication capabilities, from prototypes to high-volume orders, ensure your parts meet exact mechanical and thermal demands. Contact us today to discuss how our engineered PTFE solutions can solve your specific challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech