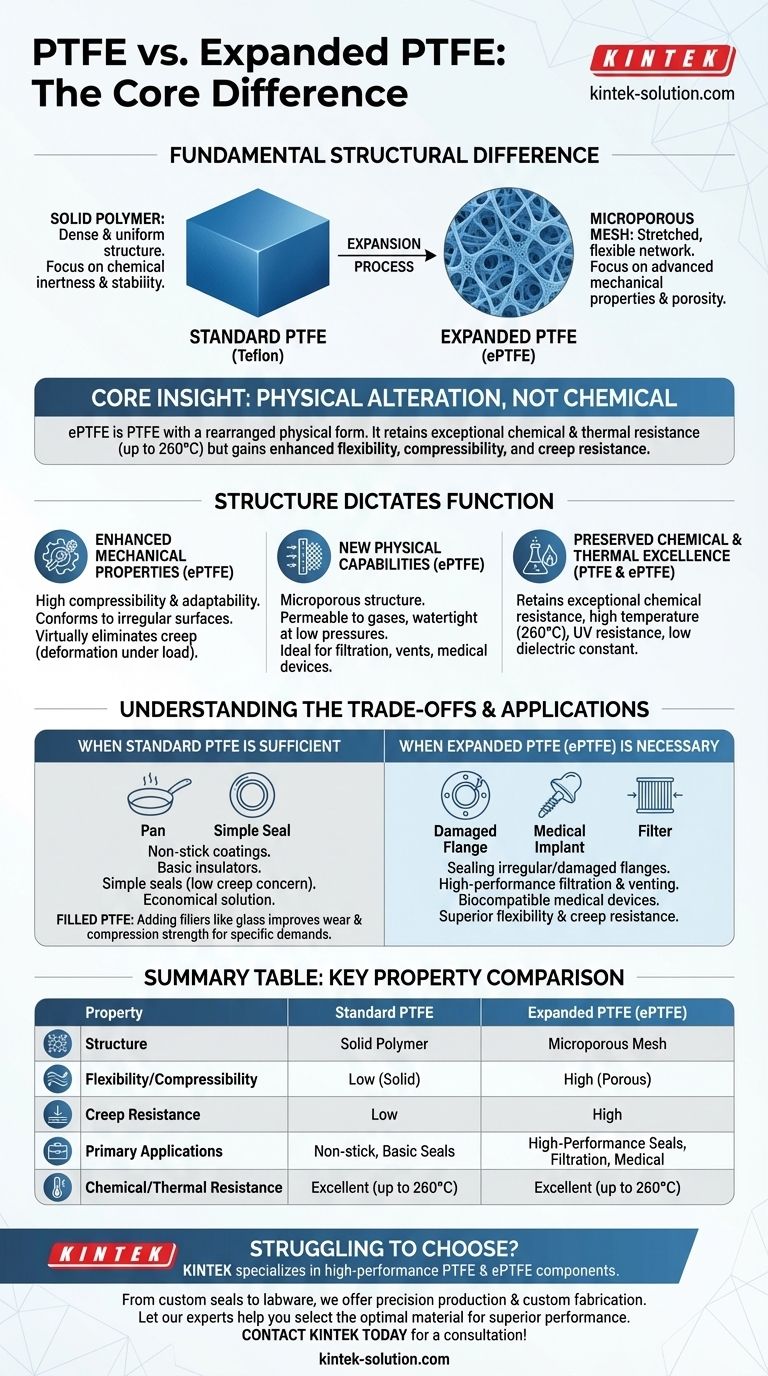

The fundamental difference is structural: standard Polytetrafluoroethylene (PTFE) is a solid polymer, whereas expanded PTFE (ePTFE) is a microporous form of the same material. The expansion process stretches PTFE, transforming it from a solid block into a flexible, mesh-like structure of microfibers and pores, which imparts unique mechanical properties while retaining PTFE's exceptional chemical resistance.

The core insight is that ePTFE is not a different chemical, but a physically altered version of PTFE. This structural change from solid to porous is what gives ePTFE enhanced flexibility, compressibility, and creep resistance, making it suitable for demanding sealing and filtration applications where standard PTFE would fail.

From Solid Polymer to Microporous Mesh

To understand the difference in application, you must first understand the difference in physical form. The choice between PTFE and ePTFE is almost always a decision about mechanical properties, not chemical ones.

The Foundation: Standard PTFE

Standard PTFE, widely known by the brand name Teflon, is a dense, solid polymer.

Its reputation is built on its remarkable chemical inertness and stability. It's used as a non-stick coating, a chemical-resistant sealer, and a reliable electrical insulator.

The Innovation: Expanded PTFE (ePTFE)

Expanded PTFE is created by physically stretching standard PTFE in a controlled, multi-directional manner.

This process rearranges the polymer into a network of interconnected microfibers and nodes, creating a microporous material. This mesh-like structure is the source of all of ePTFE's advanced capabilities.

How Structure Dictates Function

The transformation from a solid to a porous mesh fundamentally changes how the material behaves under physical stress, opening up a new range of applications.

Enhanced Mechanical Properties

The primary advantage of ePTFE lies in its superior mechanical performance, especially for sealing. It offers high compressibility and adaptability, allowing it to conform perfectly to irregular or damaged flange surfaces.

Most importantly, the multi-directional expansion process virtually eliminates creep (the tendency of a material to deform under constant load), a common limitation of standard PTFE gaskets.

New Physical Capabilities

The pores created during expansion give ePTFE unique properties. It can be engineered to be permeable to gases while remaining watertight at low pressures.

This makes it an ideal material for high-performance filters, vents, and medical devices where biocompatibility and a smooth, porous structure are critical.

Preserved Chemical and Thermal Excellence

Crucially, ePTFE retains the core benefits of its parent material. It has the same exceptional resistance to chemicals and high temperatures (up to 260°C).

It also shares PTFE's low dielectric constant, UV resistance, and non-toxic, hygienic properties. You sacrifice none of PTFE's chemical strengths to gain ePTFE's mechanical advantages.

Understanding the Trade-offs

While ePTFE offers significant advantages, it is not always the necessary choice. The right material depends entirely on the demands of the application.

When Standard PTFE is Sufficient

For applications like non-stick surface coatings, basic insulators, or simple seals where creep is not a concern, standard PTFE is often the most direct and cost-effective solution.

The Role of Filled PTFE

It's also important to note that ePTFE is not the only way to enhance PTFE's mechanical properties. Adding fillers like glass to standard PTFE can also significantly improve wear resistance, compression strength, and creep resistance.

Glass-filled PTFE is an excellent choice for applications requiring high rigidity and performance in oxidizing environments.

The Porosity Variable

Unlike solid PTFE, ePTFE can be manufactured in different densities (low, medium, and high porosity). This allows its properties to be tailored for specific tasks, from highly breathable filters to dense, high-compression gasket materials.

Making the Right Choice for Your Application

Your decision should be based on the specific mechanical and physical demands of your project.

- If your primary focus is sealing irregular, damaged, or wide-gap flanges: Choose ePTFE for its superior flexibility, compressibility, and creep resistance.

- If your primary focus is high-performance filtration, venting, or biocompatible medical implants: The unique microporous structure of ePTFE is essential.

- If your primary focus is a simple non-stick coating or basic chemical sealing: Standard PTFE is the practical and economical choice.

- If your primary focus is high wear resistance and compressive strength in a solid form: Consider a filled PTFE variant like glass-filled PTFE.

Ultimately, choosing between PTFE and ePTFE is about deciding if you need the foundational chemical resilience of a solid polymer or the advanced mechanical performance of its engineered, porous form.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid Polymer | Microporous Mesh |

| Flexibility/Compressibility | Low | High |

| Creep Resistance | Low | High |

| Primary Applications | Non-stick coatings, basic seals | High-performance seals, filtration, medical devices |

| Chemical/Thermal Resistance | Excellent (up to 260°C) | Excellent (up to 260°C) |

Struggling to choose between PTFE and ePTFE for your project?

KINTEK specializes in manufacturing high-performance PTFE and ePTFE components—from custom seals and liners to specialized labware. Our expertise in precision production and custom fabrication ensures you get the exact material properties your application demands, whether you need a prototype or a high-volume order.

Let our experts help you select the optimal material for superior performance in the semiconductor, medical, laboratory, or industrial sectors. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems