In short, Teflon (PTFE) balls are specified across a wide range of demanding industries due to their unique material properties. You will find them in the automotive, aerospace, chemical processing, medical, pharmaceutical, food, paper, and electronics sectors. Their use is driven by an exceptional ability to withstand harsh chemicals, extreme temperatures, and provide electrical insulation.

The widespread use of PTFE balls is not due to their strength, but their extraordinary resilience. They are chosen for applications where chemical inertness, extreme temperature stability, and electrical insulation are more critical than mechanical wear resistance.

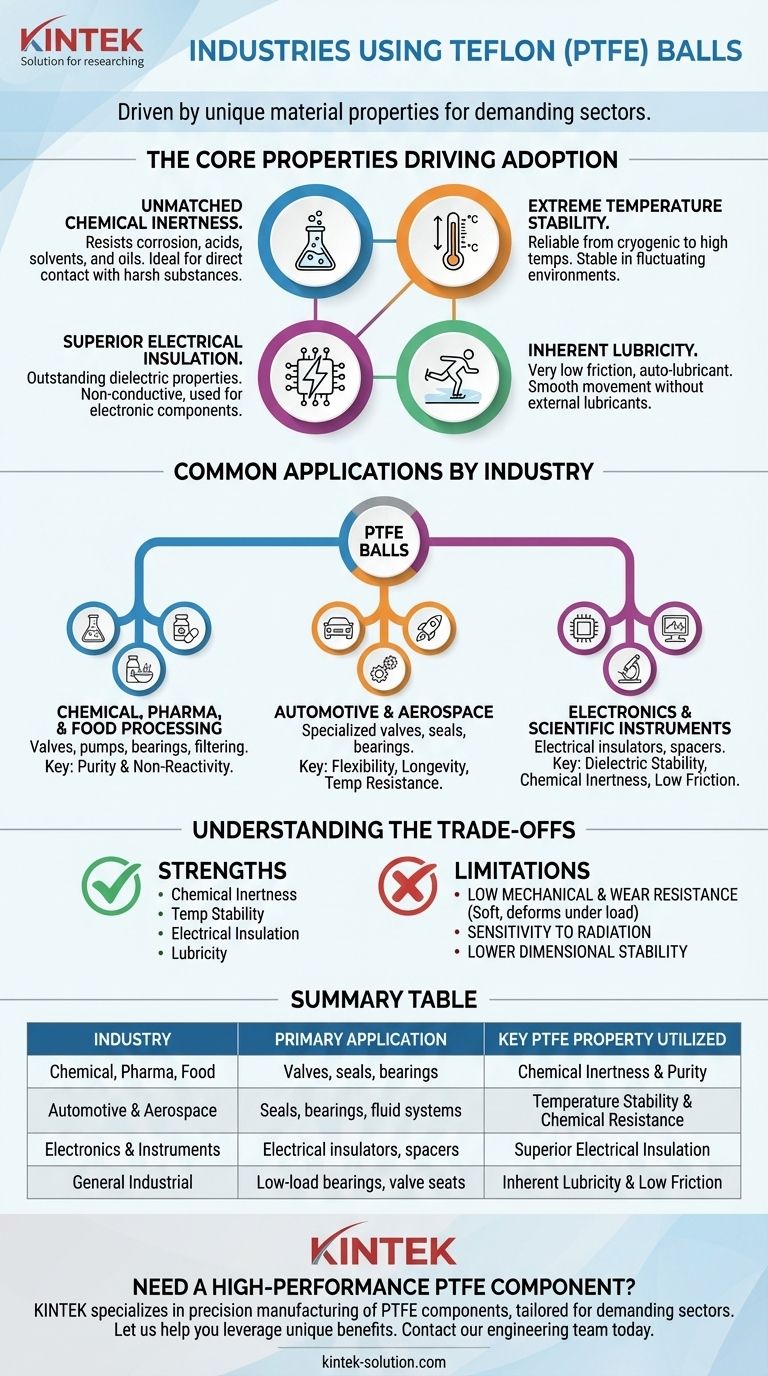

The Core Properties Driving Adoption

The decision to use a PTFE ball is almost always a decision to prioritize its unique chemical and thermal properties over raw mechanical strength. Understanding these characteristics explains its prevalence in specialized fields.

Unmatched Chemical Inertness

PTFE is famously non-reactive. It offers exceptional resistance to corrosion, acids, solvents, oils, and other aggressive chemicals.

This makes it an ideal material for components that come into direct contact with harsh substances, ensuring the integrity of both the component and the medium it handles.

Extreme Temperature Stability

PTFE performs reliably across a vast temperature spectrum. It remains flexible at cryogenic (low) temperatures and is stable in high-temperature applications.

This thermal resilience allows PTFE balls to be used in environments with extreme temperature fluctuations, from aerospace systems to industrial processing equipment designed to handle cryogenic liquids.

Superior Electrical Insulation

PTFE possesses outstanding electrical insulating and dielectric properties. It does not conduct electricity, making it a valuable material for electronic components.

This characteristic is critical in the electronics industry, where PTFE balls can be used as insulators or non-conductive spacers in sensitive apparatus.

Inherent Lubricity

PTFE is an "auto-lubricant" material, meaning it has a very low coefficient of friction. This allows parts to move smoothly against it without external lubricants.

This property is key for its use in low-load bearings, valve seats, and seals where reducing friction is essential for performance and longevity.

Common Applications by Industry

These core properties translate directly into specific uses within key sectors. The application dictates which property is most valuable.

Chemical, Pharmaceutical, and Food Processing

In these industries, purity and non-reactivity are paramount. PTFE balls are used in special valves, pumps, bearings, and filtering apparatus that handle aggressive or sensitive media.

Because PTFE will not contaminate or react with the products, it is a trusted choice for applications with strict hygiene or chemical compatibility standards.

Automotive and Aerospace

Flexibility, longevity, and resistance to temperature extremes are critical in these sectors. PTFE balls are used in specialized valves, seals, and bearings.

They can handle exposure to various fuels and fluids while enduring the wide operating temperatures of engines and flight systems.

Electronics and Scientific Instruments

The excellent dielectric stability of PTFE makes it a primary choice for electrical insulators.

In measurement and medical instruments, its chemical inertness and low friction are also valued, ensuring that moving parts do not interfere with sensitive readings or samples.

Understanding the Trade-offs

No material is perfect. The decision to use PTFE requires acknowledging its limitations, which are just as important as its strengths.

Low Mechanical and Wear Resistance

This is the most significant trade-off. Compared to other engineering plastics, PTFE is a soft material with lower mechanical strength and poor wear resistance.

It should not be used in high-load bearings or applications involving significant abrasion, as it will deform and wear out quickly.

Sensitivity to Radiation

The properties of PTFE can be altered by exposure to electromagnetic radiation. This is a critical consideration for applications in aerospace or nuclear environments.

Lower Dimensional Stability

As a softer polymer, PTFE is more susceptible to creep and deformation under sustained load compared to harder materials like PEEK or metal. This must be accounted for in component design.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary goal. Use PTFE where its unique strengths shine and avoid it where its weaknesses would cause failure.

- If your primary focus is chemical resistance or temperature extremes: PTFE is an excellent candidate, especially in low-load systems like check valves, seals, or instrument components.

- If your primary focus is electrical insulation: PTFE's dielectric properties make it a top-tier choice for insulating components where mechanical stress is not a concern.

- If your primary focus is mechanical strength or wear resistance: You should immediately evaluate harder plastics or metals, as PTFE's softness is a significant liability in high-load or abrasive environments.

Understanding these core trade-offs allows you to specify PTFE balls with confidence, ensuring they solve the right problem for your project.

Summary Table:

| Industry | Primary Application | Key PTFE Property Utilized |

|---|---|---|

| Chemical, Pharma, Food | Valves, seals, bearings | Chemical Inertness & Purity |

| Automotive & Aerospace | Seals, bearings, fluid systems | Temperature Stability & Chemical Resistance |

| Electronics & Instruments | Electrical insulators, spacers | Superior Electrical Insulation |

| General Industrial | Low-load bearings, valve seats | Inherent Lubricity & Low Friction |

Need a High-Performance PTFE Component for Your Application?

KINTEK specializes in the precision manufacturing of PTFE components, including balls, seals, liners, and custom labware. Our expertise is tailored for demanding sectors like semiconductor, medical, laboratory, and industrial industries.

We understand that choosing the right material is critical. Let us help you leverage the unique benefits of PTFE—or recommend a better-suited material—for your specific requirements, from prototypes to high-volume production.

Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What medical applications utilize PTFE ball bearings? Precision & Safety for Implants and Equipment

- What are the key characteristics of PTFE coated fasteners? Enhance Durability in Harsh Environments

- What are the common pitfalls in high-temperature and low-temperature scenarios for seals? Avoid Costly Seal Failures

- Why is understanding the PTFE operating temperature range crucial for design integration? Ensure Component Reliability

- What additional processing option is available for PTFE balls? Enable Secure Bonding with Chemical Etching

- What factors influence the design variations of PTFE valves? Select the Perfect Valve for Your Application

- What are the electrical properties of PTFE balls? Unmatched Insulation for Demanding Applications

- Why is PTFE often used in electric actuated butterfly valves? Achieve Reliable, Automated Flow Control