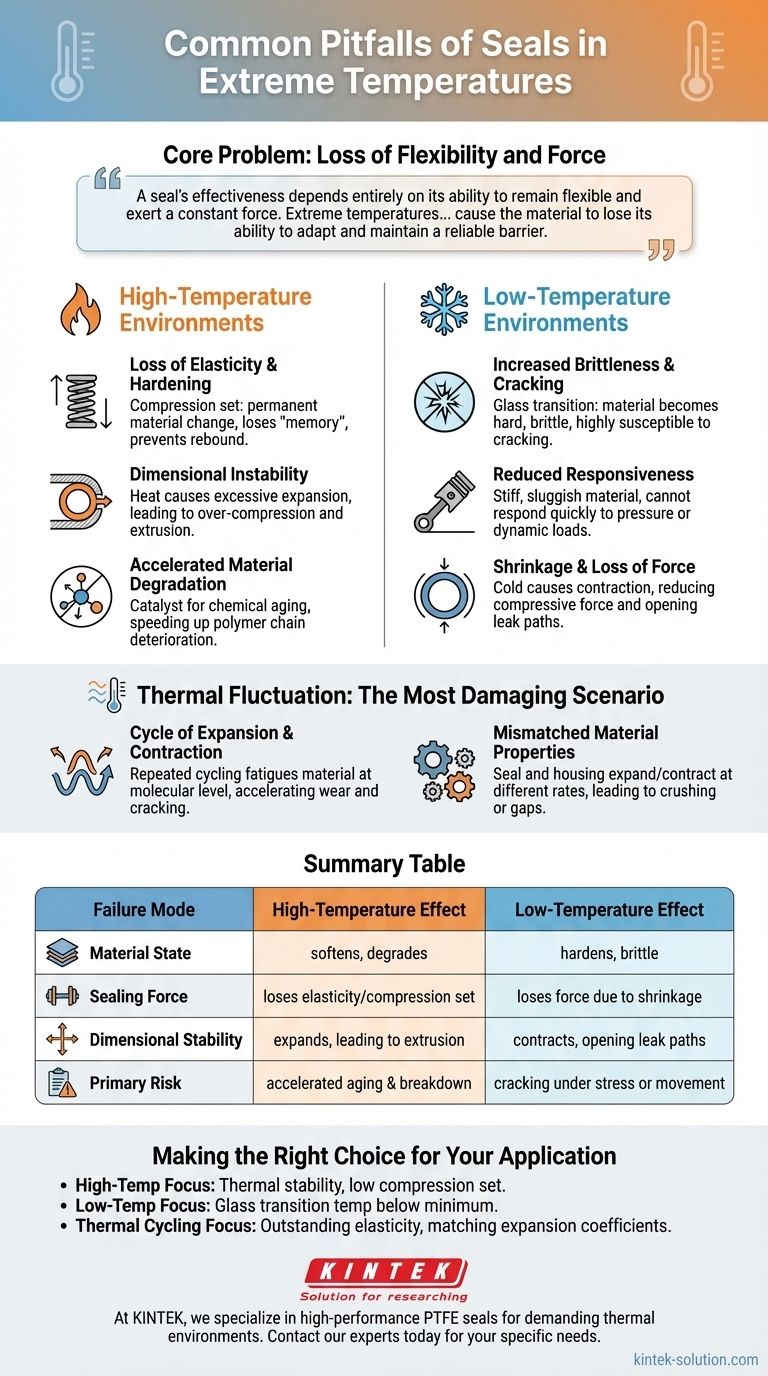

At extreme temperatures, seals fail because the material's fundamental physical properties change. In high-temperature scenarios, seals soften, lose their shape, and degrade, while in low-temperature environments, they become hard, brittle, and unresponsive, creating inevitable leak paths.

The core problem is that a seal's effectiveness depends entirely on its ability to remain flexible and exert a constant force. Extreme temperatures, both high and low, attack these very properties, causing the material to lose its ability to adapt and maintain a reliable barrier.

The Challenge of High-Temperature Environments

When a seal operates above its designed temperature range, its material structure begins to break down. This leads to a cascade of failures that compromise its integrity.

Loss of Elasticity and Hardening

Prolonged exposure to heat can cause a permanent change in the seal material, a phenomenon known as compression set. The material loses its "memory" and becomes hard, preventing it from rebounding to fill the sealing gap.

Dimensional Instability

Heat causes materials to expand. A seal can expand so much within its groove that it experiences over-compression, leading to physical damage or extrusion. This makes it unable to function correctly when the system returns to a normal temperature.

Accelerated Material Degradation

High temperatures act as a catalyst, speeding up the chemical aging of the seal's polymer chains. This causes the material to deteriorate much faster than it would under normal conditions, drastically shortening its operational lifespan.

The Challenge of Low-Temperature Environments

Operating below a material's intended temperature range is equally dangerous. The seal's properties change in the opposite direction, but the result is the same: a failed seal.

Increased Brittleness and Cracking

As temperatures drop, seal materials reach their "glass transition temperature," where they transform from a flexible, rubber-like state to a hard, brittle, glass-like state. A brittle seal cannot handle pressure spikes or dynamic movement and is highly susceptible to cracking.

Reduced Responsiveness

A cold seal becomes stiff and sluggish. It cannot respond quickly to changes in pressure or dynamic loads from moving parts. This lack of responsiveness means it can't maintain the consistent contact force required for effective sealing.

Shrinkage and Loss of Force

Just as heat causes expansion, cold causes contraction. As a seal shrinks, the compressive force it exerts on the housing surfaces is reduced. This can open a microscopic leak path that grows as the temperature continues to drop.

Understanding the Core Pitfall: Thermal Fluctuation

Often, the most damaging scenario is not a constant high or low temperature but a system that cycles between them. This fluctuation creates unique and severe stresses on the sealing system.

The Cycle of Expansion and Contraction

Repeatedly expanding and contracting a seal fatigues the material at a molecular level. This constant stress accelerates wear, worsens compression set, and can cause premature cracking far more quickly than a stable temperature would.

Mismatched Material Properties

The seal material and the metal housing it sits in expand and contract at different rates. During a temperature swing, this mismatch can alternately crush the seal (when hot) or open a gap around it (when cold), creating a highly unreliable sealing condition.

Making the Right Choice for Your Application

To avoid these pitfalls, you must match the seal material's properties to the specific thermal demands of your system.

- If your primary focus is high-temperature performance: Select a material with excellent thermal stability and a low compression set value at your target operating temperature.

- If your primary focus is low-temperature performance: Choose a material with a glass transition temperature well below your minimum operating temperature to ensure it remains flexible.

- If your primary focus is managing thermal cycling: Prioritize a material with outstanding elasticity and consider how its coefficient of thermal expansion compares to the housing material.

Understanding these temperature-induced failure modes is the first step toward designing a robust and reliable sealing system.

Summary Table:

| Failure Mode | High-Temperature Effect | Low-Temperature Effect |

|---|---|---|

| Material State | Softens, degrades | Hardens, becomes brittle |

| Sealing Force | Loses elasticity (compression set) | Loses force due to shrinkage |

| Dimensional Stability | Expands, leading to extrusion | Contracts, opening leak paths |

| Primary Risk | Accelerated aging & breakdown | Cracking under stress or movement |

Don't let temperature extremes compromise your system's integrity.

At KINTEK, we specialize in manufacturing high-performance PTFE seals and components designed to withstand the most demanding thermal environments—from cryogenic conditions to high-heat processes in semiconductor, medical, and industrial applications. Our precision production and custom fabrication capabilities ensure your seals maintain flexibility, force, and reliability.

Let us provide the right sealing solution for you, from prototype to high-volume production.

Contact our experts today to discuss your specific temperature and material requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry