The key characteristics of PTFE coated fasteners are exceptional corrosion resistance, an extremely low coefficient of friction, broad chemical inertness, and stability across a wide range of temperatures. These properties transform a standard metal fastener into a high-performance component capable of withstanding environments where uncoated fasteners would quickly degrade and fail.

The core purpose of a PTFE coating is not to increase a fastener's strength, but to create a durable, protective shield. This shield allows the underlying metal fastener to maintain its mechanical integrity in environments defined by chemical exposure, corrosive agents, or extreme friction.

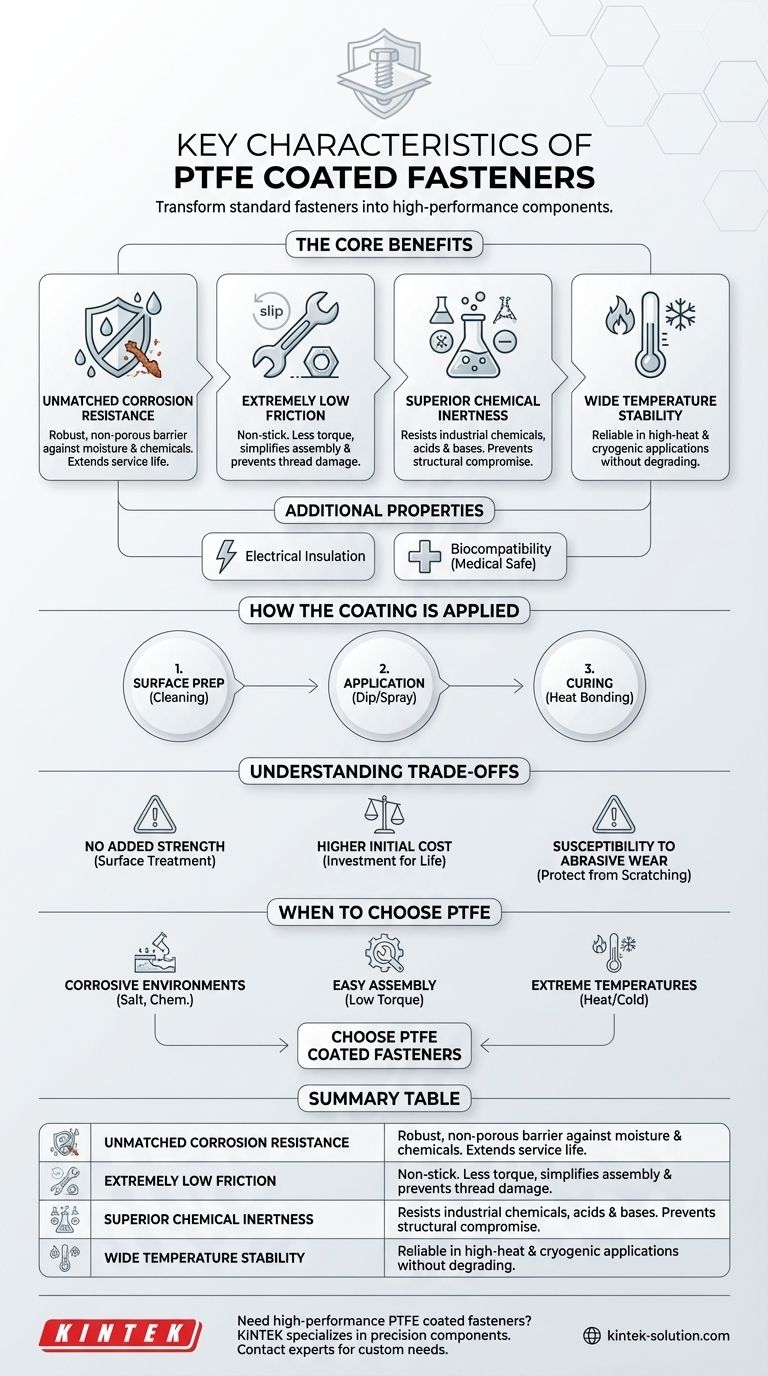

The Core Benefits of a PTFE Coating

The value of a PTFE coating is defined by several key performance advantages that solve common engineering challenges.

Unmatched Corrosion Resistance

The PTFE layer acts as a robust, non-porous barrier between the fastener's metal substrate and its environment.

This shield effectively isolates the metal from corrosive agents like moisture, saltwater, and harsh industrial chemicals, preventing rust and degradation and dramatically extending the fastener's service life.

Extremely Low Friction

PTFE is famous for its non-stick properties, giving it one of the lowest coefficients of friction of any solid material.

For fasteners, this means less torque is required for installation, which simplifies assembly and reduces the risk of thread damage. It also ensures easier, more predictable removal, even after long-term service in harsh conditions.

Superior Chemical Inertness

This coating is non-reactive with the vast majority of industrial chemicals, acids, and bases.

This characteristic makes PTFE coated fasteners essential for equipment used in chemical processing, pharmaceuticals, and oil and gas, where exposure to aggressive substances is constant. The coating prevents chemical attack that could compromise the fastener's structural integrity.

Wide Temperature Stability

PTFE coatings maintain their properties in both high-temperature and cryogenic applications.

This thermal stability allows them to be used in processes involving sterilization, high-heat machinery, or extreme cold without becoming brittle or degrading, ensuring consistent performance.

Additional Protective Properties

Beyond the primary benefits, PTFE also provides excellent electrical insulation, which is critical for preventing galvanic corrosion between dissimilar metals. For certain applications, its biocompatibility also makes it safe for contact with human tissues in medical devices.

How the Coating is Applied

The performance of a PTFE coated fastener depends heavily on a precise, multi-stage manufacturing process.

Surface Preparation is Critical

The fastener's metal surface must be thoroughly cleaned and pre-treated. This step is crucial for removing any contaminants and creating an ideal surface for the coating to adhere to.

Application Methods

The PTFE coating is typically applied as a liquid dispersion using methods like dip coating or spray coating. These techniques are designed to ensure a uniform, consistent layer across the entire fastener, including the complex geometry of its threads.

The Curing Process

After application, the fasteners are cured at elevated temperatures. This process bakes the coating, causing it to chemically bond to the metal substrate and form the hard, durable, and protective finish.

Understanding the Trade-offs

While highly effective, PTFE coated fasteners are not a universal solution. Understanding their limitations is key to using them correctly.

Mechanical Strength is Unchanged

The PTFE coating is a surface treatment; it does not add to the tensile or shear strength of the base fastener. The mechanical limits are still defined by the underlying metal, whether it's steel, stainless steel, or another alloy.

Higher Initial Cost

The multi-step manufacturing process and the cost of the raw PTFE material make these fasteners more expensive than their standard, uncoated counterparts. This investment is justified by longer service life and lower maintenance costs in demanding environments.

Susceptibility to Abrasive Wear

While durable, the PTFE coating can be compromised by significant physical abrasion or scratching. If the protective layer is scraped away, the exposed base metal becomes vulnerable to corrosion, defeating the purpose of the coating.

When to Choose PTFE Coated Fasteners

Selecting the right fastener comes down to identifying the primary challenge you need to solve.

- If your primary focus is survival in corrosive environments: Choose PTFE coated fasteners for their ability to create an inert barrier against saltwater, chemicals, and moisture.

- If your primary focus is easy assembly and disassembly: The low-friction surface is ideal for preventing thread galling and reducing the torque needed for both installation and removal.

- If your primary focus is performance in extreme temperatures: The coating's thermal stability ensures reliability in applications involving high heat or cryogenic cold.

Ultimately, PTFE coated fasteners are a specialized solution for extending the life and reliability of critical connections in challenging operational conditions.

Summary Table:

| Key Characteristic | Primary Benefit |

|---|---|

| Exceptional Corrosion Resistance | Creates a non-porous barrier against moisture, saltwater, and chemicals. |

| Extremely Low Coefficient of Friction | Reduces installation torque and prevents thread galling. |

| Superior Chemical Inertness | Resists a vast majority of industrial acids, bases, and solvents. |

| Wide Temperature Stability | Performs reliably in both high-heat and cryogenic conditions. |

Need high-performance PTFE coated fasteners for your critical application?

KINTEK specializes in manufacturing precision PTFE components, including custom-coated fasteners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your fasteners provide the durable, protective shield needed to extend service life and enhance reliability in the most demanding environments.

Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems