In automated valve systems, material selection is paramount. Polytetrafluoroethylene (PTFE) is frequently specified for the seats in electric actuated butterfly valves because of its unique combination of properties. Its extreme chemical resistance, very low coefficient of friction, and broad temperature stability make it the ideal material for ensuring reliable, long-lasting performance in demanding, automated environments.

The choice of PTFE is not just about resisting chemicals; it's about enabling the precision and endurance of an automated system. Its low-friction, inert nature allows the electric actuator to perform its job efficiently over thousands of cycles without degradation or failure.

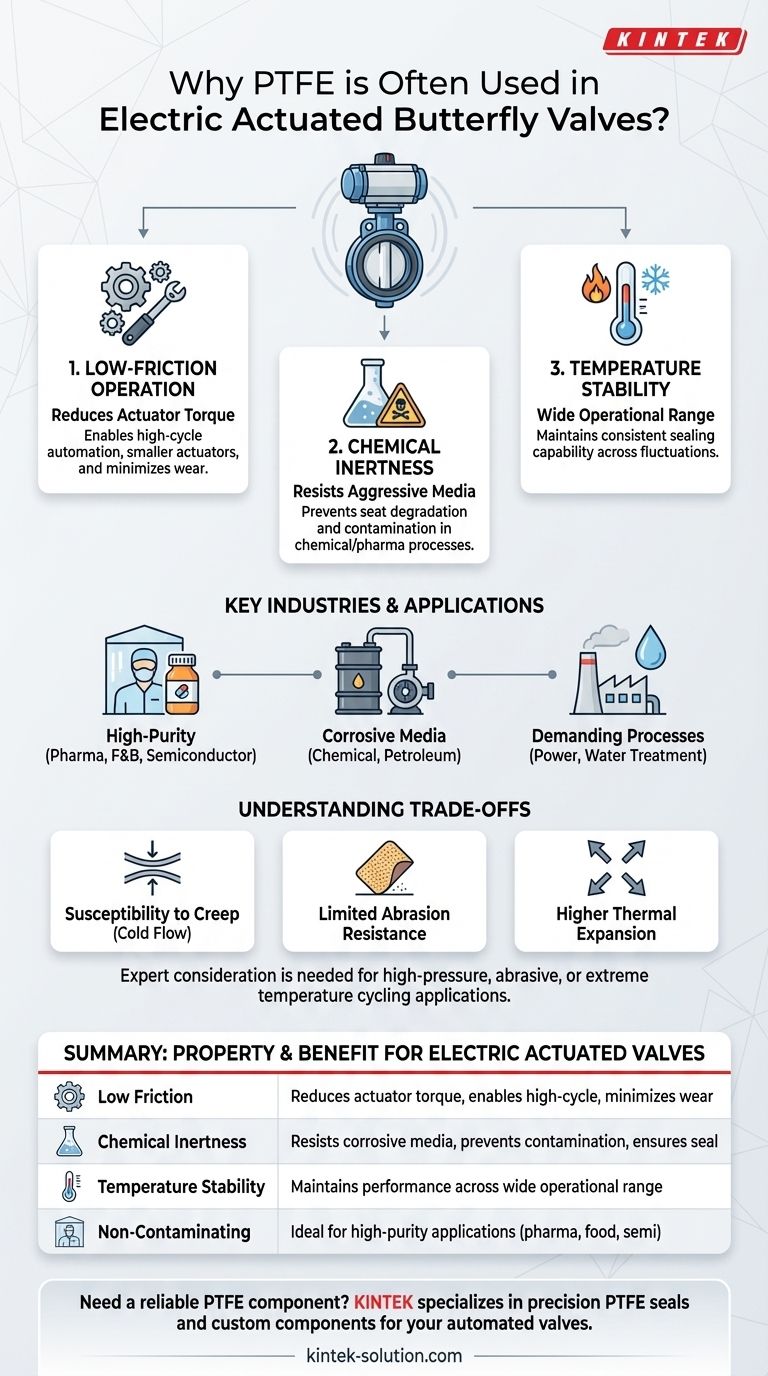

Why Material Properties Are Magnified in Actuated Systems

An electric actuated valve is part of a system that demands consistency and reliability. The choice of the valve's soft parts, like the seat, has a direct impact on the performance and longevity of the entire automated assembly.

The Critical Need for Low-Friction Operation

An electric actuator must generate enough torque to overcome the valve's friction and seal the disc. PTFE's exceptionally low coefficient of friction directly reduces this required torque.

This allows for the use of smaller, more energy-efficient actuators. More importantly, it minimizes wear on the seat and disc with every cycle, which is essential for high-cycle applications where the valve may operate hundreds of times a day.

The Demand for Absolute Chemical Inertness

Automated systems often control the flow of aggressive or corrosive media in chemical, petrochemical, or pharmaceutical processing.

PTFE is virtually inert to almost all industrial chemicals. This prevents the valve seat from swelling, degrading, or leaching, which would otherwise compromise the seal and contaminate the process media.

Ensuring Stability Across Wide Temperature Ranges

Industrial processes rarely occur at a single, stable temperature. They often involve fluctuations from ambient to elevated temperatures.

PTFE maintains its integrity and sealing capability across a wide operational temperature range, ensuring the valve provides a consistent, leak-free seal regardless of thermal conditions.

Key Industries and Applications

The properties of PTFE make it a default choice for valves in some of the most sensitive and demanding industrial sectors.

High-Purity Environments

Industries like pharmaceuticals, food and beverage, and semiconductor manufacturing rely on PTFE. Its inert, non-contaminating surface ensures that nothing leaches into the process media, meeting stringent standards for purity and safety.

Corrosive and Aggressive Media

For chemical processing, petroleum, and environmental protection sectors, PTFE-lined butterfly valves are indispensable. They provide a robust barrier against highly corrosive fluids, protecting the valve's metal body and ensuring system integrity.

Demanding Industrial Processes

Facilities in power generation, water treatment, and paper manufacturing use these valves to handle everything from corrosive fluids to slurries. PTFE's combination of chemical resistance and smooth operation proves invaluable in these environments.

Understanding the Trade-offs of PTFE

While highly effective, PTFE is not a universal solution. An expert advisor must acknowledge the material's inherent limitations to ensure proper application.

Susceptibility to Creep (Cold Flow)

Under sustained pressure, especially at elevated temperatures, pure PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, can potentially compromise the long-term integrity of the seal in very high-pressure applications.

Limited Abrasion Resistance

Pure PTFE is a relatively soft material. While suitable for many slurries, it can be susceptible to wear from sharp, abrasive particles found in mining or certain chemical slurry applications. In these cases, a reinforced or alternative seat material may be required.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. Valve designers must account for this high coefficient of thermal expansion to ensure a tight seal is maintained across the entire operational temperature range.

Making the Right Choice for Your Application

Selecting the right valve seat material comes down to matching its properties to your primary operational goal.

- If your primary focus is chemical purity and non-contamination: PTFE is the industry standard for applications in food, beverage, and pharmaceuticals.

- If your primary focus is handling highly corrosive media: A PTFE seat or fully lined valve provides an exceptional barrier, ensuring a reliable seal and long service life.

- If your primary focus is high-cycle automation: PTFE's low friction is critical for reducing actuator strain and maximizing the operational life of the valve assembly.

- If you are dealing with high pressures or abrasive particles: You may need to specify a reinforced PTFE (RTFE) or an alternative elastomer to mitigate wear and potential deformation.

By understanding these core properties and trade-offs, you can confidently specify PTFE for automated systems where performance and reliability are non-negotiable.

Summary Table:

| Property | Benefit for Electric Actuated Valves |

|---|---|

| Low Friction | Reduces actuator torque, enables high-cycle operation, minimizes wear |

| Chemical Inertness | Resists corrosive media, prevents contamination, ensures seal integrity |

| Temperature Stability | Maintains performance across a wide operational range |

| Non-Contaminating | Ideal for high-purity applications (pharma, food, semiconductor) |

Need a reliable PTFE component for your automated valve system? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your electric actuated valves deliver maximum performance and longevity. Contact our experts today to discuss your specific requirements, from prototypes to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications