The primary additional processing option for PTFE balls is chemical etching. This specialized surface treatment is designed to solve one of the material's most defining challenges: its inability to be bonded to other surfaces using conventional adhesives.

Polytetrafluoroethylene (PTFE) is famous for its extremely low surface energy, making it inherently non-stick. Chemical etching is the standard industrial process used to modify this surface, raising its energy to allow for reliable adhesive bonding.

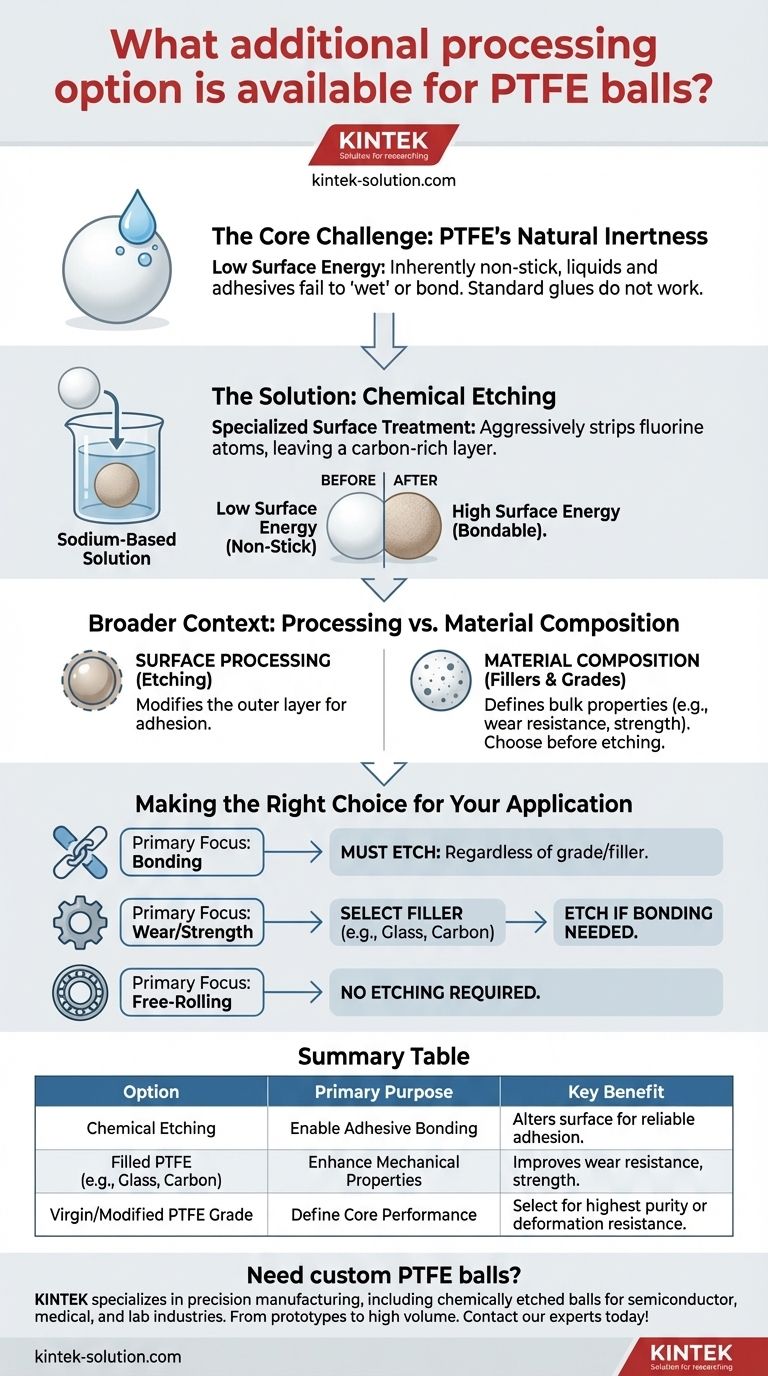

The Core Challenge: PTFE's Natural Inertness

To understand the need for etching, we must first understand the fundamental nature of PTFE. Its properties make it incredibly useful but also present a unique challenge for assembly.

The Problem of Low Surface Energy

PTFE has one of the lowest coefficients of friction and lowest surface energies of any solid material. This is why it is used for non-stick coatings on cookware.

On a molecular level, this means that liquids, including adhesives, cannot "wet" the surface properly. Instead of spreading out to create a bond, they bead up and fail to adhere.

The Barrier to Assembly

This non-stick property makes it nearly impossible to glue or bond an untreated PTFE ball to another component, whether it's metal, plastic, or another substrate. Standard epoxies and glues will simply not stick.

How Chemical Etching Solves the Bonding Problem

Chemical etching is not a coating; it is a chemical reaction that permanently alters the outermost layer of the PTFE ball.

The Etching Process

The process involves exposing the PTFE surface to a potent chemical agent, typically a sodium-based solution. This agent aggressively strips fluorine atoms from the PTFE's long polymer chains.

A Chemically Altered Surface

Removing the fluorine atoms leaves behind a carbon-rich, or "carbonaceous," layer. This new surface is visually distinct, often appearing light brown or tan.

Crucially, this new layer has a much higher surface energy than the original PTFE. It is now chemically receptive to a wide range of adhesives, including epoxies and cyanoacrylates.

Enabling Adhesion

The sole purpose of this process is to create a bondable surface. An etched PTFE ball can be securely fixed in place, allowing it to be used in assemblies where it might function as a valve seat, an insulator, or a contact point that requires both low friction and a secure mounting.

Understanding the Broader Context

While etching is a post-production process, it's important to distinguish it from choices made during material formulation.

Processing vs. Material Composition

Chemical etching modifies the surface of a finished ball. Fillers and material grades, on the other hand, define the bulk properties of the material itself.

Choosing Fillers

Fillers like glass, carbon, graphite, or bronze are added to the raw PTFE resin before it is molded. These are chosen to enhance specific mechanical properties like wear resistance, compressive strength, or thermal conductivity.

Selecting a Grade

The grade, such as Virgin or Ultra-Modified PTFE, determines the core performance characteristics of the material. Virgin PTFE offers the highest purity and chemical resistance, while modified grades can offer improved durability or lower deformation under load.

Making the Right Choice for Your Application

Your final specification depends entirely on the intended function of the PTFE ball within your design.

- If your primary focus is bonding the ball to another component: Chemical etching is a mandatory processing step, regardless of the PTFE grade or filler used.

- If your primary focus is enhancing wear resistance or strength: You must first select a PTFE material with the appropriate filler (e.g., glass or carbon) and then specify etching if that part also needs to be bonded.

- If your primary focus is using the ball as a loose, free-rolling element: No etching is necessary, as adhesion is not required for the application.

Ultimately, understanding these options allows you to leverage PTFE's exceptional properties without being limited by its inherent inertness.

Summary Table:

| PTFE Ball Option | Primary Purpose | Key Benefit |

|---|---|---|

| Chemical Etching | Enable Adhesive Bonding | Alters surface for reliable adhesion to other components. |

| Filled PTFE (e.g., Glass, Carbon) | Enhance Mechanical Properties | Improves wear resistance, strength, and durability. |

| Virgin/Modified PTFE Grade | Define Core Performance | Select for highest purity or improved deformation resistance. |

Need a custom PTFE ball that bonds securely? KINTEK specializes in precision manufacturing of PTFE components, including chemically etched balls for the semiconductor, medical, and laboratory industries. We offer custom fabrication from prototypes to high-volume orders to ensure your parts meet exact specifications. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments