In the medical field, Polytetrafluoroethylene (PTFE) ball bearings are utilized in two primary domains: critical long-term implants, such as heart valves, and high-precision medical equipment, including syringe plungers and laboratory pump seals. Their selection is driven by a unique combination of biological inertness and extremely low friction, which ensures both patient safety and mechanical reliability.

The core reason PTFE is trusted in medical bearings is its ability to provide clean, frictionless movement without reacting to the human body or harsh sterilization processes. This makes it one of the few materials suitable for functioning inside a patient or in sterile laboratory environments.

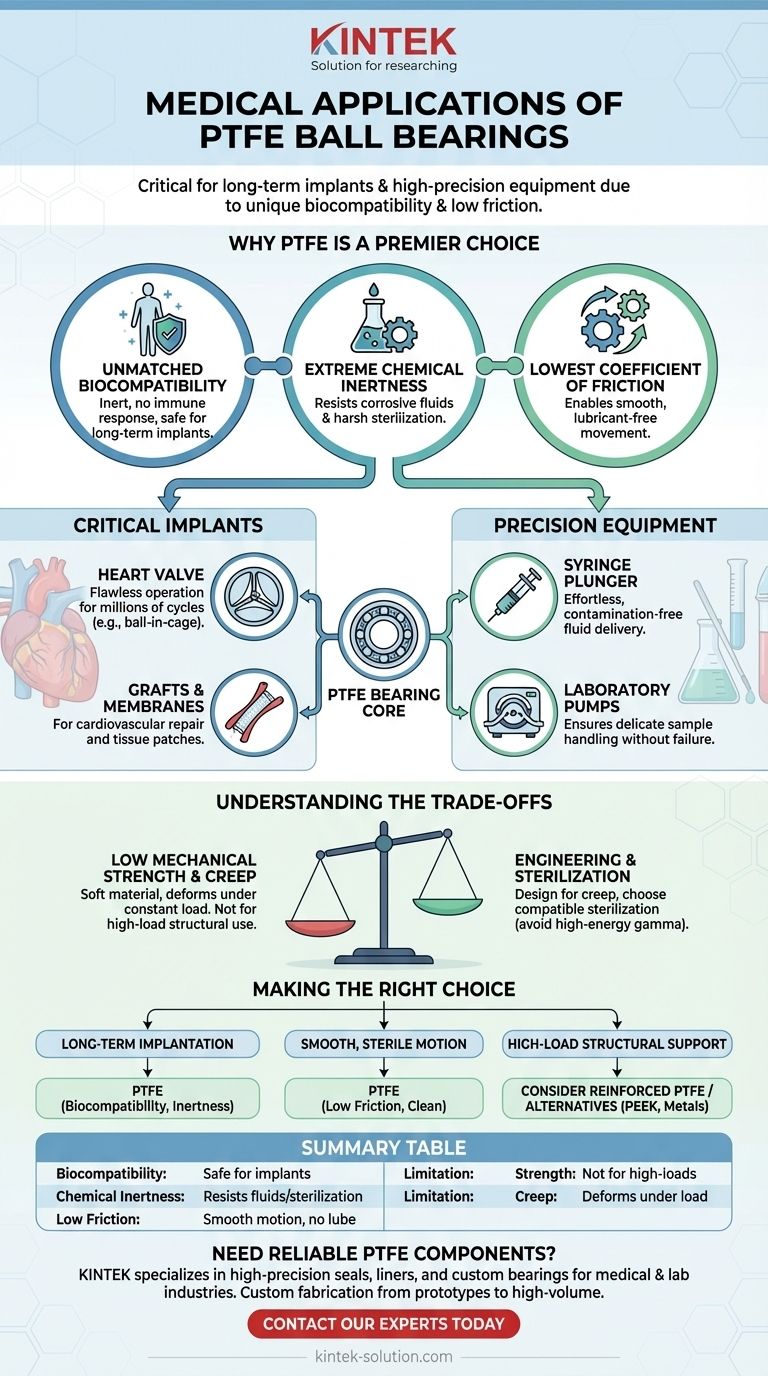

Why PTFE is a Premier Choice for Medical Bearings

The suitability of PTFE for medical applications is not based on a single characteristic but on a combination of three critical material properties. These properties solve fundamental challenges in medical device engineering.

Unmatched Biocompatibility

The most important factor for any implanted material is biocompatibility. PTFE is exceptionally inert and does not provoke an immune response or rejection from human tissue. This allows it to reside within the body for extended periods without causing adverse effects, a mandatory requirement for devices like heart valves or artificial joints.

Extreme Chemical Inertness

PTFE is resistant to virtually all chemicals, including corrosive bodily fluids and aggressive sterilization agents. This ensures the material will not degrade over time, maintaining its structural integrity and performance throughout the device's lifespan. It also means the device can be reliably sterilized without being damaged.

The Lowest Coefficient of Friction

PTFE boasts one of the lowest coefficients of friction of any solid material. This allows components to move smoothly against each other without the need for liquid lubricants, which would be impossible to use inside the human body. This property is essential for the consistent, millions-of-cycles performance required of a heart valve or the precise action of a syringe plunger.

Key Applications in Medical Devices

While the principles are universal, the application of PTFE bearings and components varies depending on the device's function, whether it's implanted in a patient or used in a laboratory setting.

Critical Implants: The Heart Valve Example

Perhaps the most well-known medical application is in artificial heart valves. The ball-in-cage design, a historical standard, often utilized a PTFE ball. The bearing's function here is to open and close with every heartbeat, a task it must perform flawlessly millions of times per year. PTFE's combination of biocompatibility, durability in blood, and low friction made it a viable candidate for this life-sustaining role.

Precision Laboratory and Surgical Equipment

In external medical and lab equipment, PTFE's properties prevent contamination and ensure smooth operation. It is used in syringe plungers for effortless and precise fluid delivery. In peristaltic pumps and sample transport mechanisms, PTFE seals and bearings ensure that delicate samples are handled without contamination or mechanical failure.

Beyond Bearings: Grafts and Membranes

It is important to note that PTFE's use in medicine extends beyond bearings. Its inert nature makes it suitable for cardiovascular grafts to replace blood vessels and for creating patches used in ligament and tissue repair. While these are not bearing applications, they further prove the material's fundamental compatibility with the human body.

Understanding the Trade-offs

No material is perfect, and making an informed decision requires understanding PTFE's limitations. These factors are critical for any medical device engineer to consider during the design phase.

Relatively Low Mechanical Strength

Compared to metals or other high-performance polymers, pure PTFE is a relatively soft material. It is not suitable for high-load structural applications on its own. Its strength must be carefully matched to the mechanical demands of the device.

Susceptibility to "Creep"

Under a constant load, PTFE can slowly deform over time, a phenomenon known as creep or cold flow. For long-term implants under continuous stress, this must be accounted for in the engineering design to prevent failure.

Sterilization Constraints

While resistant to chemical sterilization, some methods like high-energy gamma radiation can degrade PTFE's mechanical properties. The chosen sterilization method must be compatible with the material to ensure the final product is both sterile and safe.

Making the Right Choice for Your Goal

The decision to use PTFE should be directly tied to the primary requirements of the medical device you are designing.

- If your primary focus is long-term implantation and direct tissue contact: PTFE is a leading candidate due to its unparalleled biocompatibility and chemical inertness.

- If your primary focus is smooth, sterile, and non-contaminating motion in equipment: PTFE's low friction and resistance to cleaning agents make it ideal for components like plungers, seals, and transport mechanisms.

- If your primary focus is high-load structural support: Pure PTFE is likely insufficient; you should investigate reinforced PTFE composites or alternative materials like PEEK or medical-grade metals.

Ultimately, leveraging PTFE successfully in a medical device depends on aligning its unique properties with the specific demands of the biological or laboratory environment.

Summary Table:

| Property | Benefit for Medical Applications |

|---|---|

| Biocompatibility | Safe for long-term implants; does not provoke immune response. |

| Chemical Inertness | Resists bodily fluids and harsh sterilization processes. |

| Low Friction | Enables smooth, reliable motion without liquid lubricants. |

| Limitation: Strength | Not suitable for high-load applications without reinforcement. |

| Limitation: Creep | Can deform under constant load; must be engineered for. |

Need reliable PTFE components for your medical device?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom bearings—for the semiconductor, medical, and laboratory industries. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get parts that meet the stringent demands of biocompatibility and performance.

Let's discuss how our precision PTFE solutions can enhance the safety and reliability of your medical or lab equipment.

Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application