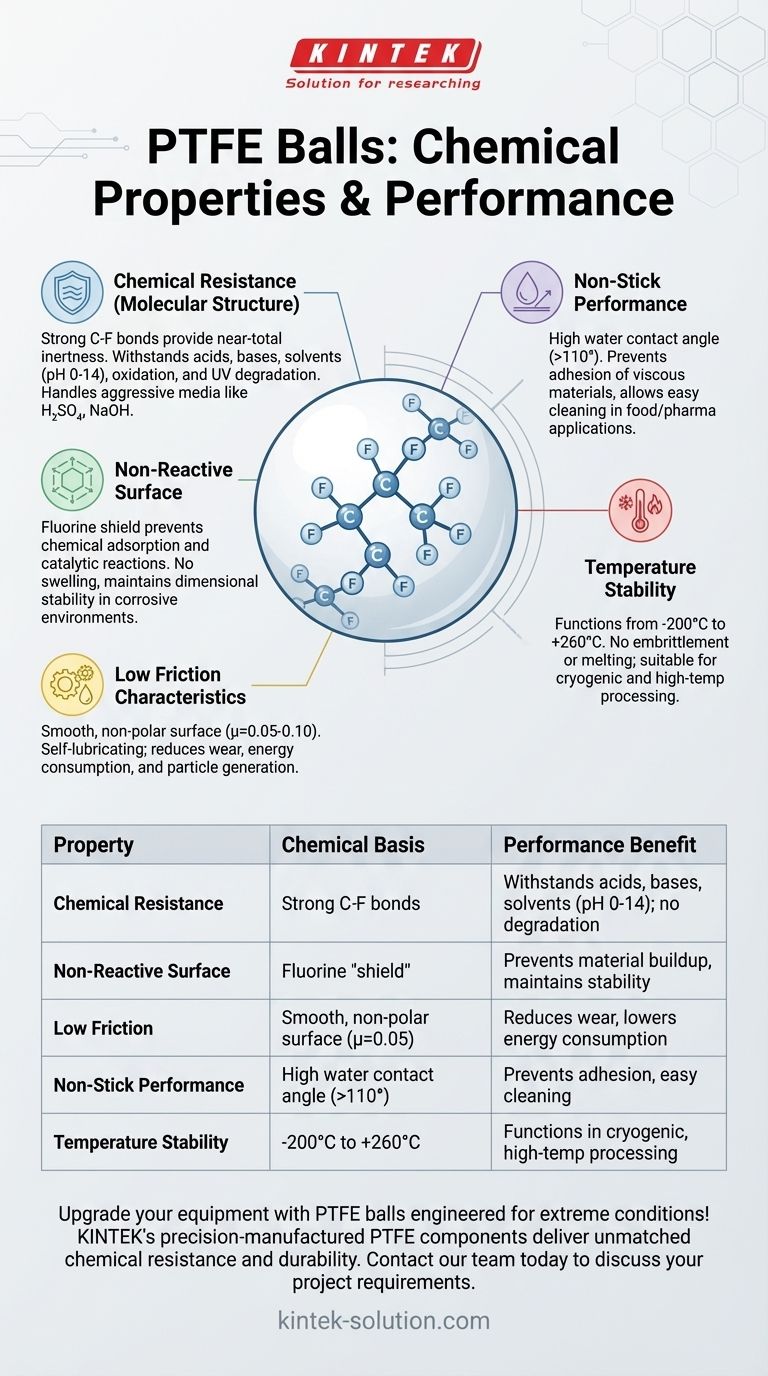

PTFE (polytetrafluoroethylene) balls exhibit exceptional performance in demanding applications due to their unique chemical properties. The strong carbon-fluorine bonds in their molecular structure provide unparalleled chemical resistance, enabling them to withstand corrosive environments. Their low friction coefficient and non-stick characteristics further enhance durability by reducing wear and preventing material buildup. These properties make ptfe balls ideal for valves, bearings, and other mechanical components operating in harsh conditions.

Key Points Explained:

-

Chemical Resistance from Molecular Structure

- PTFE's linear chain structure consists of strong carbon-fluorine bonds (one of the strongest in organic chemistry)

- This molecular arrangement creates:

- Near-total inertness to most chemicals (acids, bases, solvents)

- Exceptional stability across pH ranges (0-14)

- Resistance to oxidation and UV degradation

- Practical implication: Can handle aggressive media like concentrated sulfuric acid or sodium hydroxide solutions

-

Non-Reactive Surface Properties

- The fluorine "shield" around the carbon backbone prevents:

- Chemical adsorption (materials won't bond to the surface)

- Catalytic reactions that degrade other materials

- Results in:

- No swelling or deformation when exposed to chemicals

- Maintained dimensional stability in corrosive environments

- Long-term performance without degradation

- The fluorine "shield" around the carbon backbone prevents:

-

Low Friction Characteristics

- The smooth, non-polar surface creates:

- Coefficient of friction as low as 0.05-0.10 (among the lowest of any solid)

- Self-lubricating properties without additives

- Benefits include:

- Reduced wear in dynamic applications (e.g., pump bearings)

- Lower energy consumption in moving systems

- Minimal particle generation in cleanroom applications

- The smooth, non-polar surface creates:

-

Non-Stick Performance

- The fluorinated surface exhibits:

- Extremely high water contact angle (>110°)

- Prevention of adhesion for viscous materials

- Operational advantages:

- Prevents buildup in valves handling sticky fluids

- Allows easy cleaning in food/pharma applications

- Reduces maintenance frequency in processing equipment

- The fluorinated surface exhibits:

-

Temperature Stability

- Maintains properties across wide range (-200°C to +260°C):

- No embrittlement at cryogenic temperatures

- No melting point (sinters around 327°C)

- Enables use in:

- Cryogenic storage systems

- High-temperature chemical processing

- Thermal cycling applications

- Maintains properties across wide range (-200°C to +260°C):

Have you considered how these properties combine to make PTFE balls particularly valuable in multi-parameter challenging environments? Their unique chemistry enables solutions where metals fail from corrosion and other plastics degrade. From semiconductor manufacturing to chemical processing plants, these unassuming spheres perform critical functions through their extraordinary molecular design.

Summary Table:

| Property | Chemical Basis | Performance Benefit |

|---|---|---|

| Chemical Resistance | Strong C-F bonds | Withstands acids, bases, solvents (pH 0-14); no degradation in corrosive environments |

| Non-Reactive Surface | Fluorine "shield" | Prevents material buildup, maintains dimensional stability |

| Low Friction | Smooth, non-polar surface (μ=0.05) | Reduces wear, lowers energy consumption, minimizes particle generation |

| Non-Stick Performance | High water contact angle (>110°) | Prevents adhesion in valves/processing equipment; easy cleaning |

| Temperature Stability | Stable from -200°C to +260°C | Functions in cryogenic storage, high-temperature processing, and thermal cycling |

Upgrade your equipment with PTFE balls engineered for extreme conditions!

KINTEK's precision-manufactured PTFE components deliver unmatched chemical resistance and durability for semiconductor, medical, and industrial applications. Whether you need standard solutions or custom-designed parts for specialized environments, our expertise ensures optimal performance.

Contact our team today to discuss your project requirements and discover how our PTFE solutions can solve your most challenging material problems.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In which industries are PTFE envelope gaskets commonly used? A Guide to Chemical Resistance and Purity

- What advantages do PTFE bars offer in chemical industries? Ensure Safety and Efficiency in Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the characteristics of unfilled PTFE sheets made from virgin PTFE resin? Achieve Ultimate Purity and Performance

- In which industries are PTFE mill-type envelope gaskets applied? Ensure Leak-Free Sealing in Demanding Environments

- What makes PTFE reducing flanges an excellent choice for piping systems? Achieve Superior Corrosion Resistance and Reliability

- How do PTFE components compare to metal components? Choose the Right Material for Your Application

- What are the properties of PTFE encapsulated O-rings? Superior Sealing for Harsh Environments