In short, PTFE balls offer a unique combination of extreme chemical inertness, a vast operational temperature range, and an inherently low coefficient of friction that metals cannot match. These properties make PTFE the superior choice for applications involving corrosive substances, cryogenic to high-heat conditions, or where self-lubrication is a critical requirement.

The decision between PTFE and metal is not about which material is universally "better," but which is precisely suited for the operating environment. Metals offer superior strength and rigidity, while PTFE provides unparalleled resistance to chemical attack and friction in extreme temperatures.

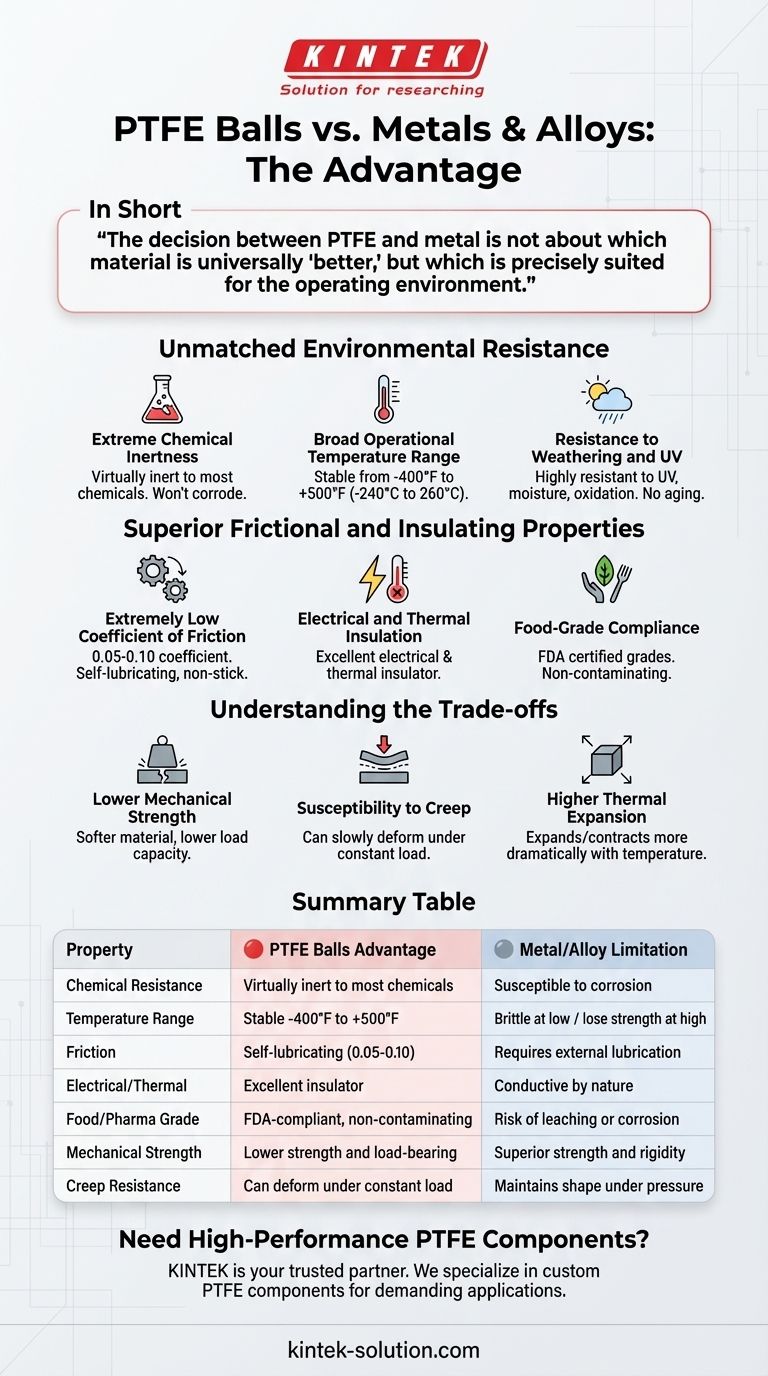

Unmatched Environmental Resistance

The primary advantage of PTFE lies in its ability to perform reliably in environments that would cause metals to corrode, seize, or fail. It offers a level of stability that is difficult to achieve with even specialized alloys.

Extreme Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, solvents, and corrosive gases. Unlike metals and alloys, which are susceptible to rust and chemical degradation, PTFE balls will not corrode or react when exposed to these substances. This ensures product purity and component longevity in chemically aggressive systems.

Broad Operational Temperature Range

PTFE maintains its properties across an exceptionally wide temperature spectrum, from cryogenic lows of -400°F (-240°C) to high heat of +500°F (260°C). While metals can become brittle at low temperatures or lose strength at high temperatures, PTFE remains stable and functional.

Resistance to Weathering and UV

Unlike many materials that degrade over time with exposure to sunlight and weather, PTFE is highly resistant to UV radiation, moisture, and oxidation. This prevents the embrittlement and aging that can affect other plastics and even some metal coatings, making it ideal for long-term outdoor applications.

Superior Frictional and Insulating Properties

Beyond environmental resilience, PTFE possesses inherent physical characteristics that make it a uniquely effective material for specialized mechanical and electrical applications.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, typically ranging from 0.05 to 0.10. This creates a self-lubricating, non-stick surface perfect for check valves, rotating parts, and sliding applications where external lubricants are undesirable or impractical. Metals, in contrast, require lubrication to prevent galling and wear.

Electrical and Thermal Insulation

Metals are, by nature, conductive. PTFE is an excellent electrical insulator (possessing good dielectric properties) and a thermal insulator. This makes PTFE balls the only viable choice for applications where components must prevent the flow of electricity or heat.

Food-Grade Compliance

Many grades of PTFE are certified by the FDA for direct contact with food and pharmaceuticals. Its non-reactive and non-stick nature ensures that it will not contaminate the processed media, a critical advantage over many metals that can leach or corrode.

Understanding the Trade-offs

To make an informed decision, it is crucial to recognize that PTFE's advantages come with compromises in mechanical performance compared to metals.

Lower Mechanical Strength

The most significant trade-off is mechanical strength. PTFE is a much softer material than any metal or alloy and has substantially lower compressive strength and load-bearing capacity. It is not suitable for high-load or high-impact structural applications where metals excel.

Susceptibility to Creep

Under a constant load, PTFE can slowly deform over time, a phenomenon known as creep. Metals and alloys are far more rigid and maintain their shape under sustained pressure, making them the standard for dimensionally critical, high-stress components.

Higher Thermal Expansion

While PTFE operates across a wide temperature range, its coefficient of thermal expansion is significantly higher than that of metals. This means it will expand and contract more dramatically with temperature changes, a factor that must be accounted for in the design of high-precision assemblies.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary operational challenge.

- If your primary focus is handling corrosive chemicals or extreme temperatures: PTFE is the definitive choice for its unmatched inertness and stability.

- If your primary focus is low-friction movement or self-lubrication: PTFE's naturally slick surface provides superior performance where external lubricants cannot be used.

- If your primary focus is high mechanical strength, rigidity, or load-bearing: A metal or alloy is the correct and necessary choice.

Ultimately, choosing the right material is about matching its unique strengths to the specific demands of your engineering problem.

Summary Table:

| Property | PTFE Balls Advantage | Metal/Alloy Limitation |

|---|---|---|

| Chemical Resistance | Virtually inert to most chemicals, acids, and solvents. | Susceptible to corrosion and degradation. |

| Temperature Range | Stable from -400°F to +500°F (-240°C to 260°C). | Can become brittle at low temps or lose strength at high temps. |

| Friction | Extremely low coefficient (0.05-0.10); self-lubricating. | Requires external lubrication to prevent wear. |

| Electrical/Thermal | Excellent insulator. | Conductive by nature. |

| Food/Pharma Grade | FDA-compliant, non-contaminating. | Risk of leaching or corrosion. |

| Mechanical Strength | Lower strength and load-bearing capacity. | Superior strength and rigidity. |

| Creep Resistance | Can deform under constant load over time. | Maintains shape under sustained pressure. |

Need High-Performance PTFE Components for Demanding Applications?

If your project requires the unmatched chemical resistance, wide temperature stability, or self-lubricating properties of PTFE, KINTEK is your trusted partner. We specialize in the precision manufacturing of custom PTFE components—including seals, liners, labware, and balls—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver solutions from initial prototypes to high-volume production, ensuring your components meet the exact demands of your application. Let's discuss how our expertise in PTFE can solve your unique engineering challenge.

Contact us today for a consultation

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- What are the key chemical properties of PTFE balls? Unmatched Chemical & Thermal Stability