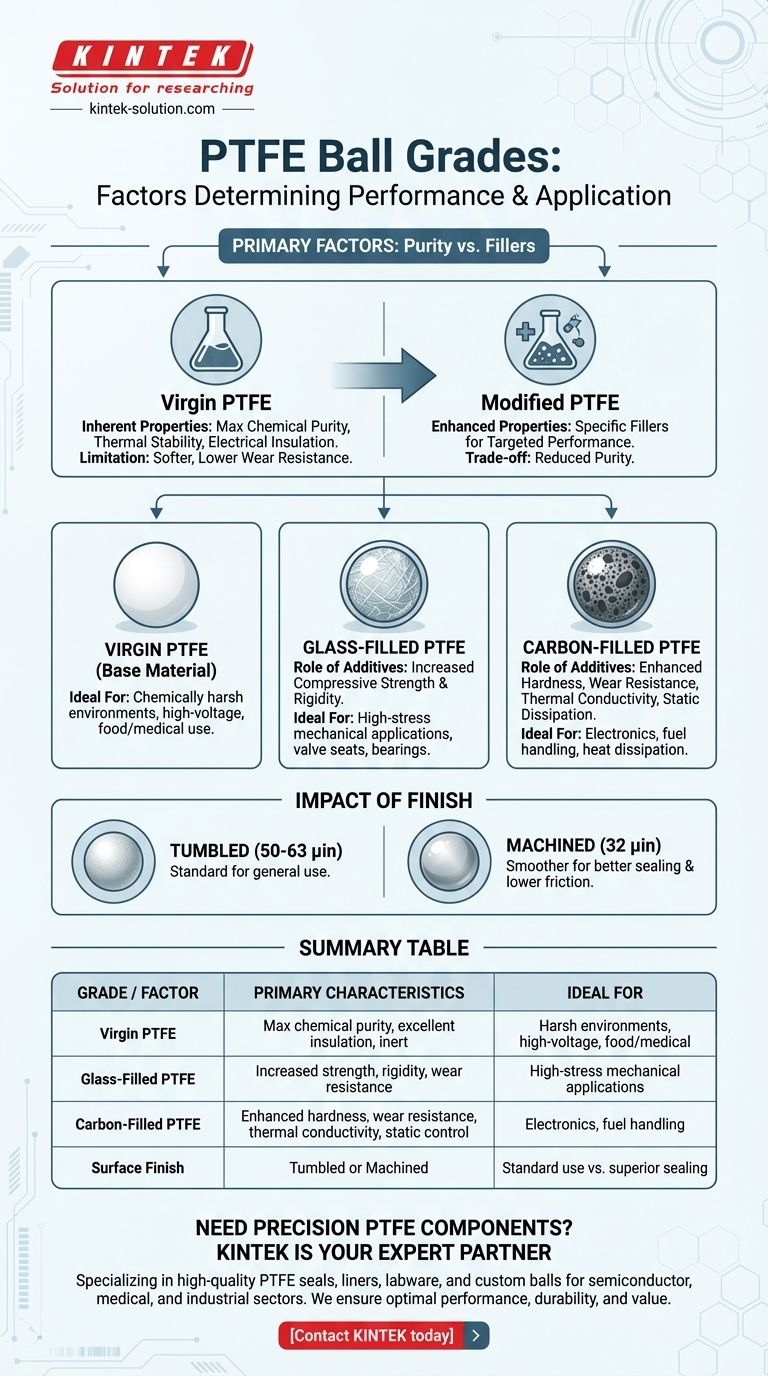

The primary factors that determine the different grades of PTFE balls are the material's purity and the inclusion of specific filler materials. These elements are chosen to enhance or modify the inherent properties of pure Polytetrafluoroethylene (PTFE) for specialized industrial applications.

While all PTFE balls offer exceptional chemical resistance and a low coefficient of friction, the distinction between grades comes down to a simple trade-off: choosing between the absolute purity of "virgin" PTFE and the enhanced mechanical performance of "modified" PTFE, which contains strengthening fillers.

The Foundation: Virgin PTFE

The baseline for all grades is "virgin" PTFE, a material defined by its exceptional intrinsic properties that stem from the powerful carbon-fluorine bonds in its molecular structure.

Inherent Chemical and Thermal Stability

Virgin PTFE is almost universally inert, resisting nearly all industrial chemicals and solvents. It also provides excellent high-temperature resistance and electrical insulating properties, making it a default choice for chemically harsh or high-voltage environments.

The Natural Limitations of PTFE

Despite its strengths, pure PTFE is a relatively soft material. This can lead to deformation under high loads (a phenomenon known as "creep") and lower wear resistance compared to harder plastics, which limits its use in high-stress mechanical applications.

How Fillers Create Specialized Grades

To overcome the mechanical limitations of virgin PTFE, manufacturers create "ultra-modified" grades by introducing filler materials during processing.

The Role of Additives

Fillers are specific additives, such as glass fibers or carbon, blended into the PTFE base. This process creates a composite material with targeted properties, moving beyond the capabilities of pure PTFE.

Common Filler: Glass Fibers

Adding glass fibers significantly increases the compressive strength and rigidity of the PTFE ball. This enhancement improves wear resistance and reduces deformation under sustained load, making it suitable for valve seats and bearings.

Common Filler: Carbon

Carbon additives serve a dual purpose. They drastically increase the hardness and wear resistance of the PTFE, but they also improve its thermal conductivity and can provide static dissipative properties, which is critical in certain electronic or fuel-handling applications.

The Impact of Manufacturing and Finish

Beyond the material composition, the final processing steps can also be considered a differentiating factor that affects performance.

Tumbled vs. Machined Surfaces

PTFE balls are commonly available with two standard surface finishes. A tumbled finish is standard, resulting in a surface roughness of 50 to 63 microinches. For applications requiring a smoother surface for better sealing or lower friction, a precision machined finish (around 32 microinches) is available.

Understanding the Trade-offs

Selecting a PTFE grade is not about finding a "better" material, but about finding the right material for a specific job. Each choice involves compromises.

Purity vs. Mechanical Performance

Using a filled PTFE grade will almost always improve mechanical properties like hardness and wear resistance. However, this comes at the cost of purity. Virgin PTFE remains the superior choice for food-grade, medical, or ultra-pure chemical applications where no contamination is permissible.

Altering Inherent Properties

Adding fillers changes the material's profile. For instance, adding carbon makes the PTFE more thermally conductive and less of a pure electrical insulator. This can be a benefit or a drawback depending entirely on the application's requirements.

Selecting the Right Grade for Your Application

Use your primary operational challenge as the guide to selecting the correct PTFE ball grade.

- If your primary focus is maximum chemical purity or electrical insulation: Choose Virgin PTFE for its unmatched inertness and dielectric properties.

- If your primary focus is high mechanical load or wear resistance: Select a glass-filled or carbon-filled grade to prevent deformation and extend service life.

- If your primary focus is thermal conductivity or static dissipation: A carbon-filled PTFE is the most effective choice.

- If your primary focus is a smooth, low-friction seal: Prioritize a machined surface finish regardless of the material grade.

Ultimately, understanding the interplay between purity, fillers, and finish empowers you to choose a PTFE ball engineered to solve your specific problem.

Summary Table:

| Grade / Factor | Primary Characteristics | Ideal For |

|---|---|---|

| Virgin PTFE | Maximum chemical purity, excellent electrical insulation, inert. | Chemically harsh environments, high-voltage applications, food/medical industries. |

| Glass-Filled PTFE | Increased compressive strength, rigidity, and wear resistance. | High-stress mechanical applications (e.g., valve seats, bearings). |

| Carbon-Filled PTFE | Enhanced hardness, wear resistance, thermal conductivity, static dissipation. | Applications requiring heat dissipation or static control (e.g., electronics, fuel handling). |

| Surface Finish | Tumbled (standard) or Machined (smoother). | Standard use vs. applications requiring superior sealing and lower friction. |

Need Precision PTFE Components? KINTEK Is Your Expert Partner

Selecting the right PTFE grade is critical for your application's success. At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, labware, and custom balls—for the semiconductor, medical, laboratory, and industrial sectors.

We don't just supply parts; we provide solutions. Our expertise ensures you get components engineered for optimal performance, durability, and value, whether you need prototypes or high-volume orders.

Let us help you solve your specific challenge. Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does Teflon benefit the construction industry? Building Safer, More Durable Structures

- What are the advantages of PTFE ball valves? Superior Chemical Resistance & Low-Torque Operation

- How can leaking in a PTFE butterfly valve be fixed? A Guide to Reliable Sealing Solutions

- Why are PTFE seals ideal for the chemical and petrochemical industries? Unmatched Chemical & Thermal Resistance

- How is expanded PTFE (ePTFE) produced? A Guide to the Controlled Stretching Process

- How do PTFE and graphite packing compare in terms of corrosion resistance? Selecting the Right Material for Your Application

- What are the electrical properties of PTFE balls? Unmatched Insulation for Demanding Applications

- Why is PTFE packing considered a reliable and cost-effective option? Maximize Uptime & Lower Costs