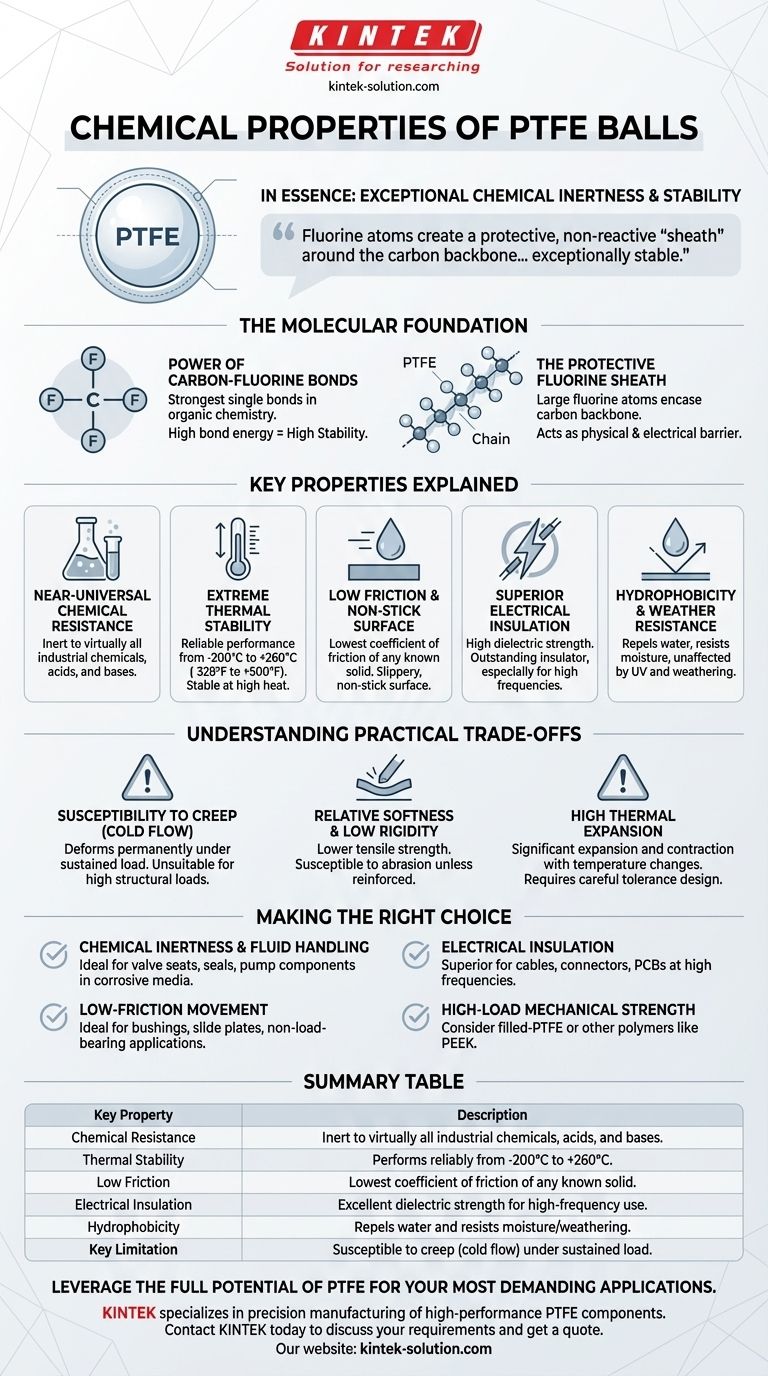

In essence, PTFE balls are defined by their exceptional chemical inertness and stability. Their key chemical properties include near-universal resistance to corrosive agents, extreme thermal stability across a wide temperature range, and a profoundly non-reactive surface. These characteristics are not accidental; they are a direct result of the powerful carbon-fluorine bonds that form the backbone of the polytetrafluoroethylene (PTFE) molecule.

The unique properties of PTFE are not isolated traits but a direct consequence of its molecular structure. The fluorine atoms create a protective, non-reactive "sheath" around the carbon backbone, making the material exceptionally stable and non-interactive with its environment.

The Molecular Foundation: Why PTFE Is So Unreactive

To understand PTFE, you must first understand its chemistry. The material's remarkable properties originate at the atomic level.

The Power of Carbon-Fluorine Bonds

The bond between a carbon atom and a fluorine atom (C-F) is one of the strongest single bonds known in organic chemistry. This high bond energy means it takes a tremendous amount of energy to break the molecule apart, rendering it chemically stable and non-reactive.

The Protective Fluorine Sheath

The fluorine atoms are larger than the carbon atoms they are bonded to. In the long polymer chain, these fluorine atoms form a tight, helical sheath that completely encases the carbon backbone. This sheath acts as a physical and electrical barrier, preventing other chemicals from reaching and reacting with the vulnerable carbon chain.

Key Properties Explained

This unique molecular structure gives rise to a set of highly desirable properties that make PTFE balls suitable for demanding applications.

Near-Universal Chemical Resistance

Due to the protective fluorine sheath, PTFE is inert to virtually all industrial chemicals, acids, and bases. It is often the only viable material for components used in highly corrosive environments.

Extreme Thermal Stability

PTFE balls perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). They do not become brittle at cryogenic temperatures and remain stable at high heat, only beginning to melt around 327°C (621°F).

Low Friction and Non-Stick Surface

The fluorine-rich surface has extremely low intermolecular forces, giving PTFE the lowest coefficient of friction of any known solid. This results in a slippery, non-stick surface to which very few materials will adhere.

Superior Electrical Insulation

The stable, symmetrical C-F bonds create a non-polar molecule with high dielectric strength. This makes PTFE an outstanding electrical insulator, especially for high-frequency applications where minimal signal loss is critical.

Hydrophobicity and Weather Resistance

The non-stick surface is also highly hydrophobic, meaning it repels water and resists moisture absorption. Furthermore, PTFE is unaffected by UV radiation and weathering, making it extremely durable for long-term outdoor exposure.

Understanding the Practical Trade-offs

No material is perfect. While PTFE's chemical properties are elite, its mechanical limitations are a critical design consideration. An advisor who ignores these is not giving you the full picture.

Susceptibility to Creep (Cold Flow)

PTFE's most significant drawback is its tendency to deform permanently under a sustained load, a phenomenon known as creep or cold flow. This makes pure PTFE unsuitable for high-load structural applications where dimensional stability is paramount.

Relative Softness and Low Rigidity

Compared to other engineering plastics, PTFE is a relatively soft material with lower tensile strength and rigidity. While it has good impact resistance, it is more susceptible to abrasion and wear unless reinforced with fillers like glass or carbon.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts more than most materials with changes in temperature. Designs requiring tight tolerances must account for this dimensional change to avoid component failure.

Making the Right Choice for Your Application

Your choice should be guided by your primary engineering goal.

- If your primary focus is chemical inertness and fluid handling: PTFE is an unparalleled choice for valve seats, seals, and pump components exposed to corrosive media.

- If your primary focus is low-friction movement: PTFE is ideal for non-load-bearing bushings, slide plates, and other applications where minimal friction is the main goal.

- If your primary focus is electrical insulation: Its high dielectric strength makes it a superior material for insulators in cables, connectors, and printed circuit boards, especially at high frequencies.

- If your primary focus is high-load mechanical strength: Pure PTFE is likely the wrong choice; consider a filled-PTFE compound or a different polymer like PEEK.

Ultimately, selecting PTFE is a decision for unparalleled chemical and thermal stability, provided its mechanical limitations are respected in your design.

Summary Table:

| Key Property | Description |

|---|---|

| Chemical Resistance | Inert to virtually all industrial chemicals, acids, and bases. |

| Thermal Stability | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Friction | Possesses the lowest coefficient of friction of any known solid. |

| Electrical Insulation | Excellent dielectric strength, ideal for high-frequency applications. |

| Hydrophobicity | Repels water and resists moisture absorption and weathering. |

| Key Limitation | Susceptible to creep (cold flow) under sustained load. |

Leverage the full potential of PTFE for your most demanding applications.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including balls, seals, liners, and custom labware. Our expertise ensures you get components that deliver on the promise of PTFE's unparalleled chemical inertness and thermal stability, while our custom fabrication services help you design around its mechanical limitations.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we partner with you to achieve optimal performance.

Contact KINTEK today to discuss your PTFE component requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do Teflon bearings perform in demanding applications? Superior Performance in Harsh Environments

- How does CAD/CAM software enhance the precision of CNC machined PTFE parts? Master Digital Machining for Flawless Components

- How do PTFE lined check valves integrate with modern water pump systems? Boost Efficiency and Protect Your System

- What are the key properties of PTFE pipes? Unlock Unmatched Chemical & Thermal Resistance

- What are the key properties of Expanded PTFE (EPTFE) gaskets? Solve Leaks on Damaged Flanges

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What are the main benefits of using Teflon PTFE sheets? Achieve Superior Performance in Extreme Conditions

- How do Teflon bellow mechanical seals contribute to environmental protection in pulp and paper mills? Prevent Hazardous Leaks