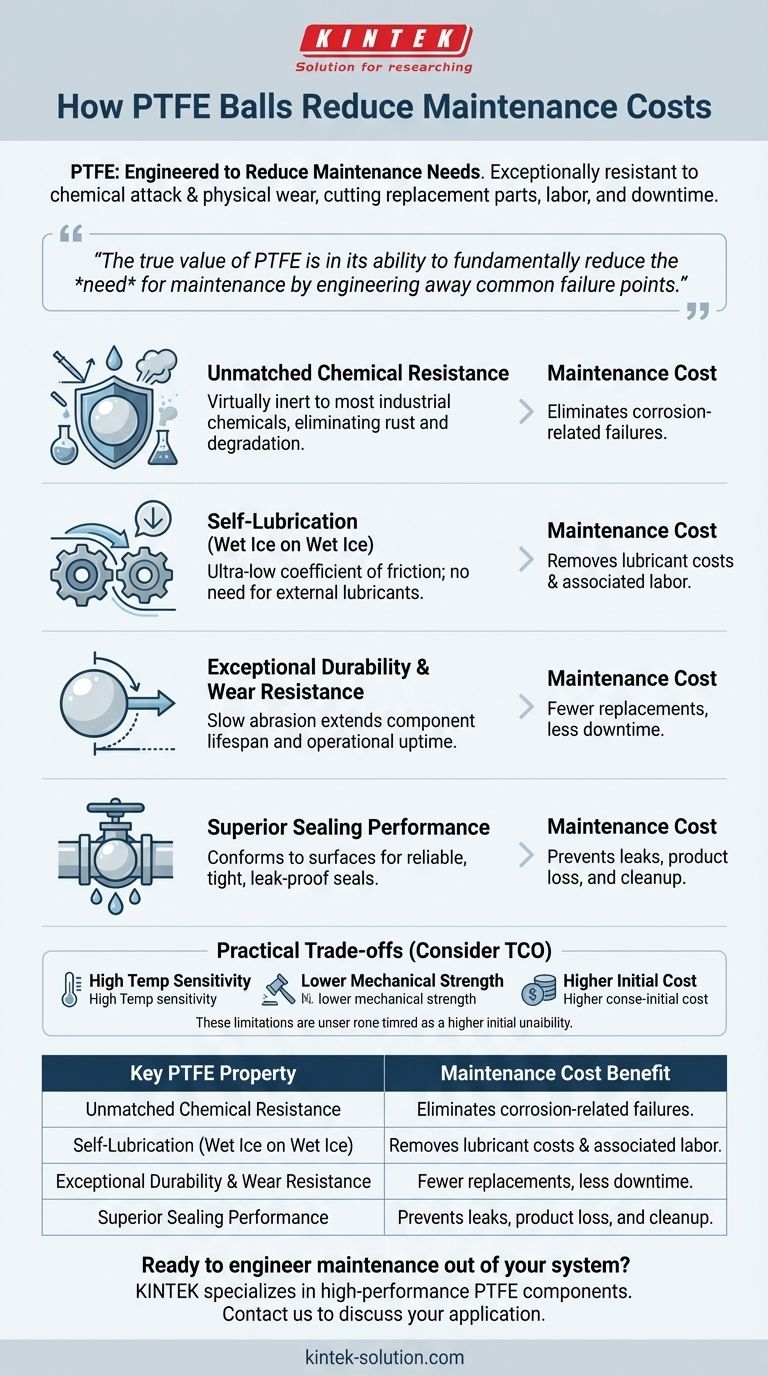

At its core, PTFE reduces maintenance costs by creating components that are exceptionally resistant to both chemical attack and physical wear. This inherent durability means parts made from PTFE, such as balls in valves, last significantly longer and require far less intervention, directly cutting down on replacement parts, labor, and system downtime.

The true value of PTFE is not just in its performance, but in its ability to fundamentally reduce the need for maintenance. Its unique properties engineer away common failure points related to corrosion, friction, and wear.

The Core Properties Driving Cost Reduction

To understand how PTFE achieves these savings, we must look at the specific material properties that translate directly into lower maintenance and operational expenses.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals and corrosive agents.

This means components like valve balls will not degrade, rust, or fail when exposed to harsh environments that would destroy traditional materials. This eliminates the primary reason for replacement in many chemical processing applications.

The Power of Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This self-lubricating nature dramatically reduces friction between moving parts. As a result, there is no need for external lubricants, saving both the cost of the lubricants and the labor required to apply them.

Exceptional Durability and Wear Resistance

The extremely low friction of PTFE directly contributes to its high wear resistance.

Because components slide past each other with minimal force, the material abrades very slowly. This extends the operational lifespan of the PTFE part and the equipment it is used in, leading to fewer replacement cycles and less planned downtime.

Superior Sealing Performance

In applications like valves, PTFE's ability to create a tight, reliable seal is critical.

Its composition allows it to conform to surfaces, preventing leaks. This reduces product loss, eliminates the need for frequent adjustments or repairs, and avoids the significant costs associated with cleaning up spills.

Understanding the Practical Trade-offs

While highly effective, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively and avoiding unexpected costs.

Sensitivity to High Temperatures

PTFE has a distinct operational temperature range. Exceeding its thermal limits can cause the material to deform or degrade, compromising its performance and leading to premature failure.

Lower Mechanical Strength

Compared to metals or harder engineering plastics, PTFE is a relatively soft material. It can be susceptible to "creep" or deformation under high static loads, making it unsuitable for certain high-pressure structural applications without reinforcement.

Initial Material Cost

PTFE components can have a higher upfront cost than parts made from conventional materials. The maintenance savings are realized over the component's lifecycle, so the total cost of ownership (TCO) must be the primary consideration, not just the initial purchase price.

Making the Right Choice for Your System

Selecting PTFE should be a strategic decision based on the specific demands of your operating environment.

- If your primary focus is reliability in corrosive environments: PTFE's chemical inertness is its greatest asset, virtually eliminating failures caused by material degradation.

- If your primary focus is reducing operational friction and wear: Its self-lubricating properties will extend the life of the entire mechanical assembly and remove the ongoing cost of lubrication.

- If your primary focus is lowering total cost of ownership: Balance the initial investment against the significant long-term savings from eliminated labor, fewer replacement parts, and drastically reduced system downtime.

Ultimately, integrating PTFE components is a strategic decision to engineer maintenance out of your system from the very beginning.

Summary Table:

| Key PTFE Property | Maintenance Cost Benefit |

|---|---|

| Chemical Resistance | Eliminates failures from corrosion and rust. |

| Self-Lubrication | Removes need for external lubricants and associated labor. |

| Wear Resistance | Extends component lifespan, reducing replacement frequency. |

| Superior Sealing | Prevents leaks and product loss, avoiding cleanup and repairs. |

Ready to engineer maintenance out of your system?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, labware, and balls—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures you get the durability and chemical resistance needed to significantly reduce your total cost of ownership.

Contact KINTEK today to discuss your application and discover how our PTFE solutions can lower your maintenance costs.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What factors should be considered when selecting PTFE seals? Ensure Perfect Sealing for Your Critical Applications

- What are O-rings and their primary function? The Key to Leak-Free Sealing in Any System

- Can PTFE washers be customized for specific needs? Achieve Perfect Fit and Functionality

- What are the key properties of PTFE for sliding bearings? Achieve Superior Load Support and Low Friction

- What are the disadvantages of PTFE gaskets? Key Limitations to Consider

- In which industries is porous PTFE applied? Solve Harsh Environment Challenges with KINTEK

- Why are PTFE lined ball valves suitable for the food and pharmaceutical industries? Ensuring Purity and Compliance

- What advantage does the PTFE lining provide in terms of environmental resistance? Unmatched Protection for Harsh Conditions