When selecting a PTFE valve, the design is fundamentally dictated by the specific demands of your application. The most critical factors influencing its variation are the required flow path (the number of "ways"), the method of system connection (port type), and the internal sealing mechanism used to control the fluid.

The "best" PTFE valve does not exist in isolation. The ideal choice is always the one whose flow configuration, port connections, and sealing style are precisely matched to the pressure, purity, and chemical requirements of your specific fluid handling system.

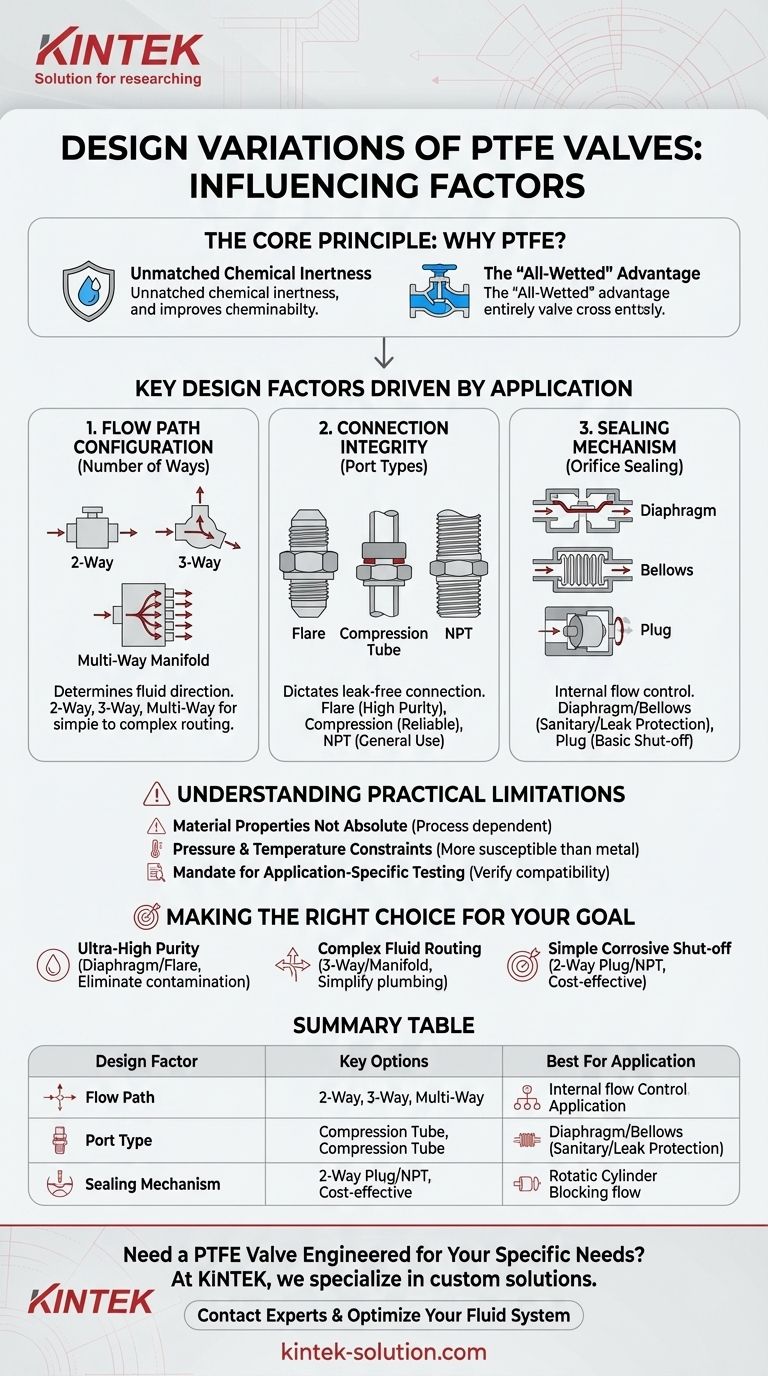

The Core Principle: Why PTFE?

Before examining design variations, it's crucial to understand why PTFE (Polytetrafluoroethylene) is chosen in the first place. Its properties define the context for every design decision.

Unmatched Chemical Inertness

The primary reason for using a PTFE valve is its extreme resistance to virtually all industrial chemicals and solvents. This makes it the material of choice for handling highly corrosive or reactive media.

The "All-Wetted" Advantage

In a true PTFE valve, all surfaces that come into contact with the fluid—the body, stem, and sealing components—are constructed from PTFE. This design ensures that the media is never exposed to materials that could corrode or introduce contaminants, which is critical for high-purity applications.

Key Design Factors Driven by Application

Your application's needs will directly determine the optimal combination of the following design features. Each choice impacts the valve's function, from simple on/off control to complex fluid routing.

1. Flow Path Configuration (Number of Ways)

This determines how the valve directs the flow of the media.

- 2-Way: This is the most common configuration, providing simple on/off or open/close functionality in a straight line.

- 3-Way: This design allows for more complex operations, such as diverting flow from one port to another or mixing two fluid streams.

- Multi-Way / Manifold: For highly complex systems, multiple valve paths can be integrated into a single manifold block, reducing connections and potential leak points.

2. Connection Integrity (Port Types)

The port type dictates how the valve physically connects to your tubing or piping. The choice is critical for ensuring a leak-free and contamination-free seal.

- Flare: Flare fittings create an extremely secure, metal-free seal ideal for ultra-high purity or aggressive chemical applications where minimizing contamination is paramount.

- Compression Tube: These fittings are common and provide a reliable seal by compressing a ferrule onto the tubing. They offer easier assembly than flare fittings.

- NPT (National Pipe Thread): Tapered pipe threads are a standard for general industrial applications but are typically avoided in high-purity systems due to the need for sealing tape or paste, which can introduce contaminants.

3. Sealing Mechanism (Orifice Sealing)

The internal mechanism that starts and stops flow is a defining feature, directly impacting performance and suitability.

- Diaphragm: This style uses a flexible PTFE diaphragm to isolate the valve's mechanical parts from the fluid path entirely. This is a top choice for sanitary and ultra-high purity applications.

- Bellows: Similar to a diaphragm, a bellows seal provides a hermetic barrier between the fluid and the valve's actuation components, offering excellent longevity and leak protection.

- Plug: A plug valve uses a simple rotating or lifting plug to block the flow path. This is a robust and straightforward design, often used for basic shut-off applications where absolute purity is less critical.

Understanding the Practical Limitations

While PTFE is a superior material, it is not without trade-offs. Acknowledging these limitations is key to successful implementation and avoiding failure.

Material Properties Are Not Absolute

The stated properties of PTFE can be influenced by the manufacturing process, the specific compound used, and other variables. The performance of a finished valve is not guaranteed by the raw material data alone.

Pressure and Temperature Constraints

Compared to metal valves, PTFE has lower tensile strength and is more susceptible to deformation under high pressure and temperature. Exceeding the manufacturer's specifications can lead to leaks or outright failure.

The Mandate for Application-Specific Testing

Ultimately, it is your responsibility to fully test and validate that the chosen valve is suitable for your specific operating conditions. Never assume compatibility; always verify performance within your actual system.

Making the Right Choice for Your Goal

To select the appropriate valve, start by defining your primary objective.

- If your primary focus is ultra-high purity: Prioritize valves with diaphragm or bellows sealing mechanisms and flare-type port connections to eliminate contamination risks.

- If your primary focus is complex fluid routing: A 3-way valve or a custom manifolded configuration will simplify your system plumbing and reduce potential leak points.

- If your primary focus is simple shut-off for a corrosive chemical: A basic 2-way plug valve with NPT or compression fittings may provide a perfectly reliable and cost-effective solution.

Understanding these core design pillars empowers you to select a valve that functions not just as a component, but as a seamless extension of your application's requirements.

Summary Table:

| Design Factor | Key Options | Best For Application |

|---|---|---|

| Flow Path | 2-Way, 3-Way, Multi-Way | Simple shut-off, flow diversion, or complex routing |

| Port Type | Flare, Compression, NPT | Ultra-high purity, reliable sealing, or general industrial use |

| Sealing Mechanism | Diaphragm, Bellows, Plug | Sanitary/High-purity, leak protection, or basic shut-off |

Need a PTFE Valve Engineered for Your Specific Needs?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom valves, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require ultra-high purity diaphragm valves with flare fittings for sensitive processes or robust plug valves for corrosive chemical handling, we deliver solutions tailored to your pressure, temperature, and fluid compatibility requirements.

Let us help you optimize your fluid system with reliable, contamination-free performance. Contact our experts today to discuss your application and receive a custom solution from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of using bronze as a filler in PTFE? Enhance Wear, Creep & Thermal Performance

- What lubrication benefits do PTFE bushes provide? Achieve Maintenance-Free, Low-Friction Performance

- What are the advantages of using PTFE guide strips in industrial applications? Enhance Equipment Life & Efficiency

- In which industries are PTFE O-Rings commonly used? Solve Extreme Sealing Challenges

- What advantages do PTFE expansion bellows have over metal bellows in corrosive environments? Superior Chemical Resistance for Longer Lifespan

- In which industries is RPTFE particularly suitable for throttle valves? Ensure Purity and Durability

- What are the unique properties of PTFE that make it suitable for CNC machining? Master Machining for Superior Components

- How many types of PTFE gaskets are there and what are their general uses? A Guide to Chemical-Resistant Sealing