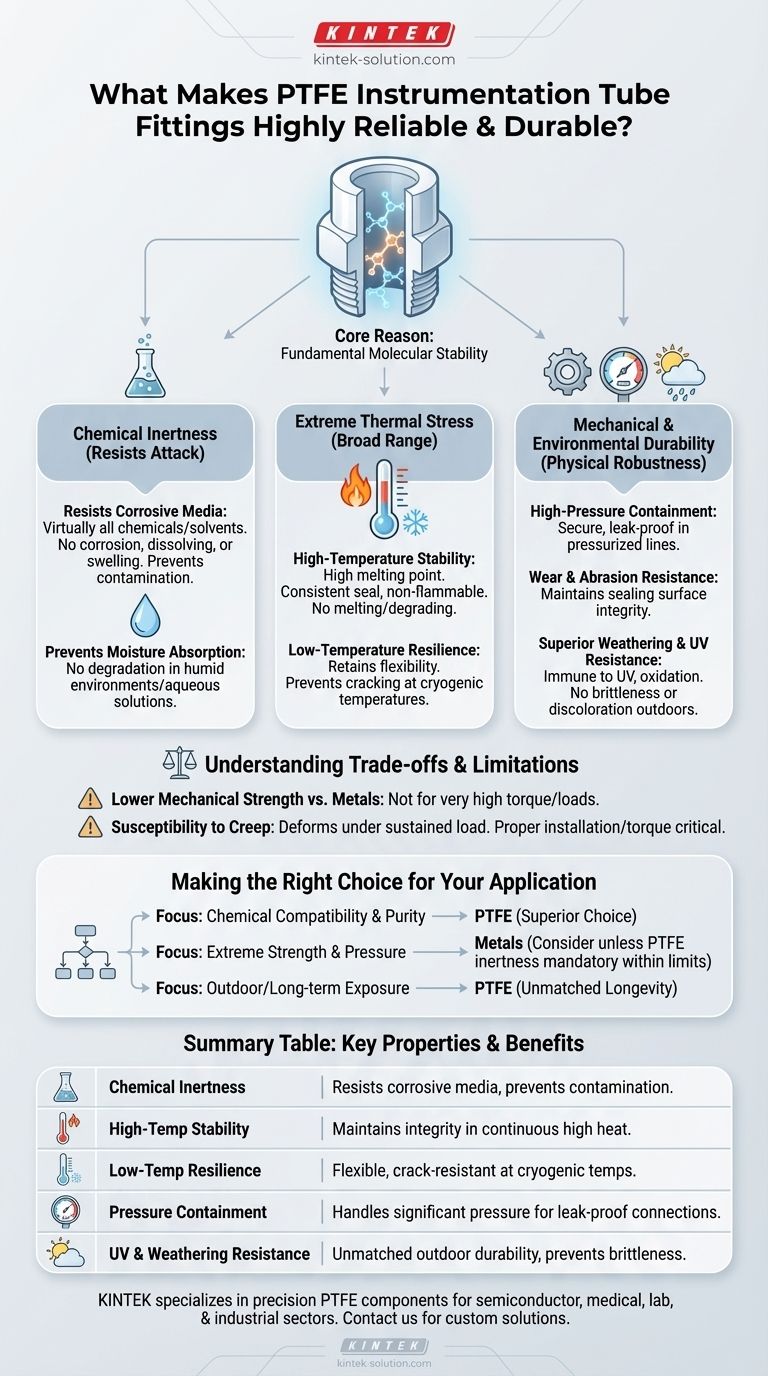

The exceptional reliability of PTFE instrumentation tube fittings is not due to a single property, but a powerful combination of core material characteristics. This includes near-universal chemical inertness, the ability to withstand extreme temperature ranges, and robust physical durability that resists wear, weathering, and high pressure.

The core reason to trust PTFE for critical applications lies in its fundamental molecular stability. This stability translates into a material that remains unchanged and effective when exposed to aggressive chemicals, high temperatures, and environmental stress, ensuring long-term, leak-free performance where other materials would degrade and fail.

The Foundation of PTFE's Reliability: Chemical Inertness

The primary reason PTFE is specified for demanding applications is its remarkable ability to resist chemical attack. This quality is not just a surface-level feature; it is integral to the material's structure.

Resisting Corrosive Media

PTFE is one of the most chemically inert polymers known. It resists nearly all industrial chemicals and solvents.

This means the fitting will not corrode, dissolve, or swell, maintaining its structural integrity and preventing contamination of the process media.

Preventing Moisture Absorption

The material is also highly resistant to moisture. This prevents degradation over time and ensures consistent performance in humid environments or with aqueous solutions.

Performance Under Extreme Thermal Stress

Instrumentation systems often operate in environments with significant temperature fluctuations. PTFE fittings are engineered to maintain their properties across a very broad thermal range.

High-Temperature Stability

PTFE has a high melting point and excellent thermal stability, allowing it to perform reliably in continuous high-temperature service without degrading, melting, or losing its shape.

This property is critical for ensuring a consistent seal and preventing component failure in heated process lines. It is also non-flammable, adding a crucial layer of safety.

Low-Temperature Resilience

Just as it performs well in heat, PTFE retains its properties, including some flexibility, at very low cryogenic temperatures.

Unlike many plastics that become brittle and crack in the cold, PTFE maintains its durability, making it suitable for a wide spectrum of applications.

Unpacking the Mechanical and Environmental Durability

Beyond chemical and thermal resistance, the physical robustness of PTFE ensures a long and predictable service life, even under mechanical and environmental stress.

High-Pressure Containment

Instrumentation tube fittings must reliably contain system pressure. PTFE is engineered to handle significant pressure ratings, ensuring a secure, leak-proof connection in pressurized gas and liquid lines.

Resistance to Wear and Abrasion

The material exhibits excellent wear resistance. This ensures that the fitting's sealing surfaces and threads maintain their integrity even with vibration or periodic disassembly and reassembly.

Superior Weathering and UV Resistance

For outdoor or exposed installations, PTFE is exceptionally durable. It is virtually immune to degradation from UV radiation, oxidation, and general weathering.

Unlike other plastics, it will not become brittle, discolor, or lose its essential properties when exposed to the elements over long periods.

Understanding the Trade-offs and Limitations

No material is perfect for every scenario. Acknowledging the limitations of PTFE is key to using it effectively and avoiding potential issues.

Lower Mechanical Strength vs. Metals

While durable for a polymer, PTFE does not possess the high tensile strength or rigidity of metal fittings like stainless steel. It is not the ideal choice for applications involving very high torque or significant external physical loads.

Susceptibility to Creep

Under a constant, sustained load (like a tightened connection), PTFE can slowly deform over time, a characteristic known as "creep."

This makes proper installation critical. Over-tightening a PTFE fitting can lead to a loss of sealing pressure and eventual leaks. Always follow the manufacturer's specified torque values.

Making the Right Choice for Your Application

Selecting the correct fitting material requires matching its properties to the primary demands of your system.

- If your primary focus is chemical compatibility and purity: PTFE is the superior choice for handling highly corrosive media or when preventing process contamination is critical.

- If your primary focus is extreme mechanical strength and pressure: Consider stainless steel or other metal alloys, unless the chemical inertness of PTFE is a mandatory requirement within its pressure limits.

- If your primary focus is outdoor or long-term environmental exposure: PTFE's unmatched resistance to UV and weathering ensures a significantly longer service life than almost any other polymer.

Ultimately, choosing PTFE is an investment in long-term stability and reliability for systems where chemical, thermal, and environmental resilience are paramount.

Summary Table:

| Key Property | Benefit for Instrumentation Fittings |

|---|---|

| Chemical Inertness | Resists virtually all corrosive media, preventing contamination and degradation. |

| High-Temp Stability | Maintains integrity and seal in continuous high-temperature service. |

| Low-Temp Resilience | Remains flexible and crack-resistant even at cryogenic temperatures. |

| Pressure Containment | Engineered to handle significant pressure ratings for leak-proof connections. |

| UV & Weathering Resistance | Unmatched durability for outdoor or exposed installations, preventing brittleness. |

Need reliable, high-purity fittings for your critical application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom instrumentation fittings—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems benefit from superior chemical resistance, thermal stability, and long-term durability, from prototype to high-volume production.

Contact KINTEK today to discuss your specific requirements and receive a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications