At their core, PTFE enveloped gaskets are composite seals designed to combine the superior chemical resistance of Polytetrafluoroethylene (PTFE) with the mechanical strength and resilience of a different core material. Their key characteristics are universal chemical inertness, a non-stick surface that prevents contamination, and the structural integrity provided by their inner core, making them a versatile solution for demanding sealing applications.

A PTFE enveloped gasket solves a critical engineering problem: pure PTFE offers unmatched chemical resistance but can fail under pressure, while stronger materials can corrode. By wrapping a robust core in a thin PTFE "envelope," you get the chemical-proof surface of PTFE combined with the mechanical sealing power of the core.

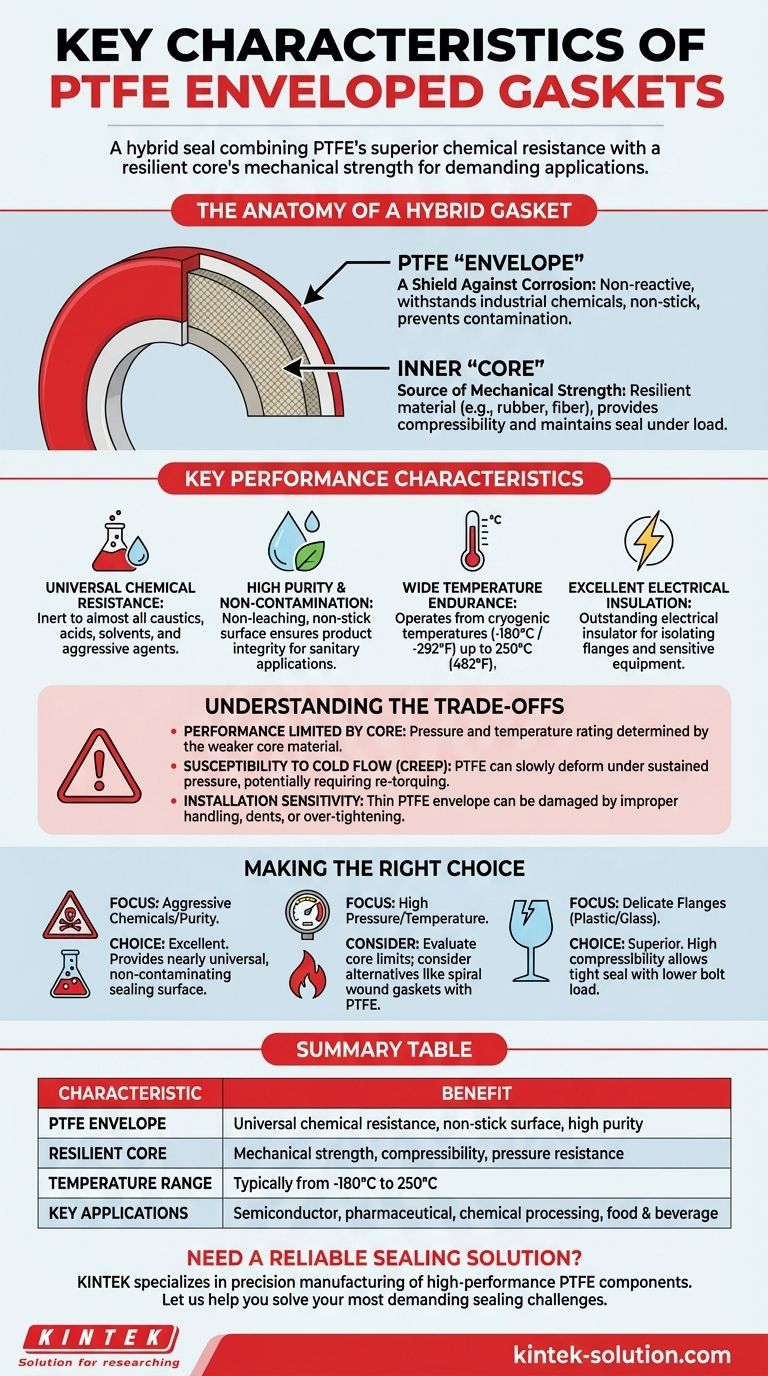

The Anatomy of a Hybrid Gasket

A PTFE enveloped gasket is not a single material but a two-part system. Understanding this structure is key to understanding its performance.

The PTFE "Envelope": A Shield Against Corrosion

The outer layer, or envelope, is made from PTFE. This is the part of the gasket that comes into contact with the process fluid.

This PTFE shell provides the gasket's signature properties: it is non-reactive and can withstand nearly all industrial chemicals.

Its surface is also non-adhesive and exceptionally smooth. This prevents process media from sticking to or contaminating the gasket surface, which is critical in food, beverage, and pharmaceutical industries.

The Inner "Core": The Source of Mechanical Strength

Inside the thin PTFE envelope sits a core insert. This core is typically made from a more compressible and resilient material, such as compressed non-asbestos fiber or a synthetic rubber like EPDM or FKM.

This inner core provides the mechanical strength that pure PTFE lacks. It allows the gasket to compress properly under bolt load, conform to flange imperfections, and maintain a tight, durable seal over time.

The core material is what gives the gasket its "memory" and resistance to the high pressures and bolt loads that would cause a solid PTFE gasket to deform or fail.

Key Performance Characteristics

The combination of the PTFE envelope and the resilient core results in a unique set of performance benefits.

Universal Chemical Resistance

Because the process fluid only touches the PTFE envelope, the gasket is protected from chemical attack across the entire pH range. It is inert to almost all caustics, acids, solvents, and other aggressive agents.

High Purity and Non-Contamination

PTFE is an inherently pure material that will not leach or contaminate the process. This, combined with its non-stick nature, ensures product integrity, making it an ideal choice for sanitary applications.

Wide Temperature Endurance

PTFE enveloped gaskets can operate across a broad temperature spectrum, typically from cryogenic temperatures around -180°C (-292°F) up to 250°C (482°F). The ultimate temperature limit is often determined by the core material.

Excellent Electrical Insulation

As a secondary benefit, PTFE is an outstanding electrical insulator. This property makes these gaskets suitable for use in isolating flanges or in sensitive electronic equipment where electrical conductivity is undesirable.

Understanding the Trade-offs

No sealing solution is perfect for every scenario. To use PTFE enveloped gaskets effectively, you must understand their limitations.

Performance is Limited by the Core Material

The gasket's overall pressure and temperature rating is dictated by the weaker of its two components. If the core material cannot handle the application temperature, it will degrade and fail, leading to a loss of seal integrity, even if the PTFE envelope remains intact.

Susceptibility to Cold Flow (Creep)

PTFE is a thermoplastic and is prone to "cold flow" or "creep"—a slow, continuous deformation under sustained pressure, especially at elevated temperatures. While the core provides support, high bolt loads can still cause the PTFE envelope to extrude, potentially requiring re-torquing to maintain a seal.

Installation Sensitivity

The PTFE envelope is relatively thin and can be damaged by improper handling or installation. Scratches, dents, or over-tightening can breach the protective layer, exposing the vulnerable core material to chemical attack and causing premature failure.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE enveloped gasket is the correct solution for your specific goal.

- If your primary focus is handling aggressive chemicals or ensuring process purity: A PTFE enveloped gasket is an excellent choice, providing a nearly universal, non-contaminating sealing surface.

- If your primary focus is high-pressure or high-temperature service: Carefully evaluate the core material's limits and consider PTFE's tendency to creep; a spiral wound gasket with PTFE filler may be a more robust alternative.

- If your primary focus is sealing delicate or non-metallic flanges (e.g., plastic or glass-lined): The high compressibility of these gaskets makes them a superior option, as they can create a tight seal with lower bolt load.

By leveraging the unique combination of a chemically inert surface and a mechanically resilient core, you can solve many of your most challenging sealing problems.

Summary Table:

| Characteristic | Benefit |

|---|---|

| PTFE Envelope | Universal chemical resistance, non-stick surface, high purity |

| Resilient Core | Mechanical strength, compressibility, pressure resistance |

| Temperature Range | Typically from -180°C to 250°C |

| Key Applications | Semiconductor, pharmaceutical, chemical processing, food & beverage |

Need a reliable sealing solution for aggressive chemicals or high-purity processes?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom PTFE enveloped gaskets. We understand the critical balance between chemical inertness and mechanical integrity required in semiconductor, medical, laboratory, and industrial applications.

Let us help you solve your most demanding sealing challenges with custom fabrication from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the compression and recovery characteristics of expanded PTFE gaskets? Achieve Superior Sealing for Delicate Flanges

- How did rotary lip seals evolve historically? From Leather to High-Performance Systems

- What role do Teflon machined parts play in chemical processing equipment? Ensure Purity & Prevent Corrosion

- What is the significance of the low friction coefficient in PTFE rotary shaft seals? Achieve Higher Speeds, Less Wear, and Lower Costs

- How does the self-lubricating property of PTFE rotary shaft seals benefit industrial applications? Achieve Maintenance-Free, High-Performance Sealing

- How can PTFE gaskets be shaped? A Guide to Cutting Methods for a Perfect Seal

- What are the advantages of mechanical seals with PTFE rings? Superior Chemical & Thermal Resistance

- What are the temperature ranges for PTFE, PEEK, and POM ball valve seats? A Guide to Material Selection