In short, mechanical seals with PTFE rings offer an unparalleled combination of chemical resistance, a wide operational temperature range, and an extremely low coefficient of friction. These properties make them the superior choice for sealing applications involving aggressive media or extreme temperatures where conventional materials would quickly fail.

The core advantage of PTFE in mechanical seals is its ability to provide reliable sealing in chemically and thermally extreme environments. However, this performance comes with a trade-off: its mechanical properties require careful consideration in high-load or high-pressure applications.

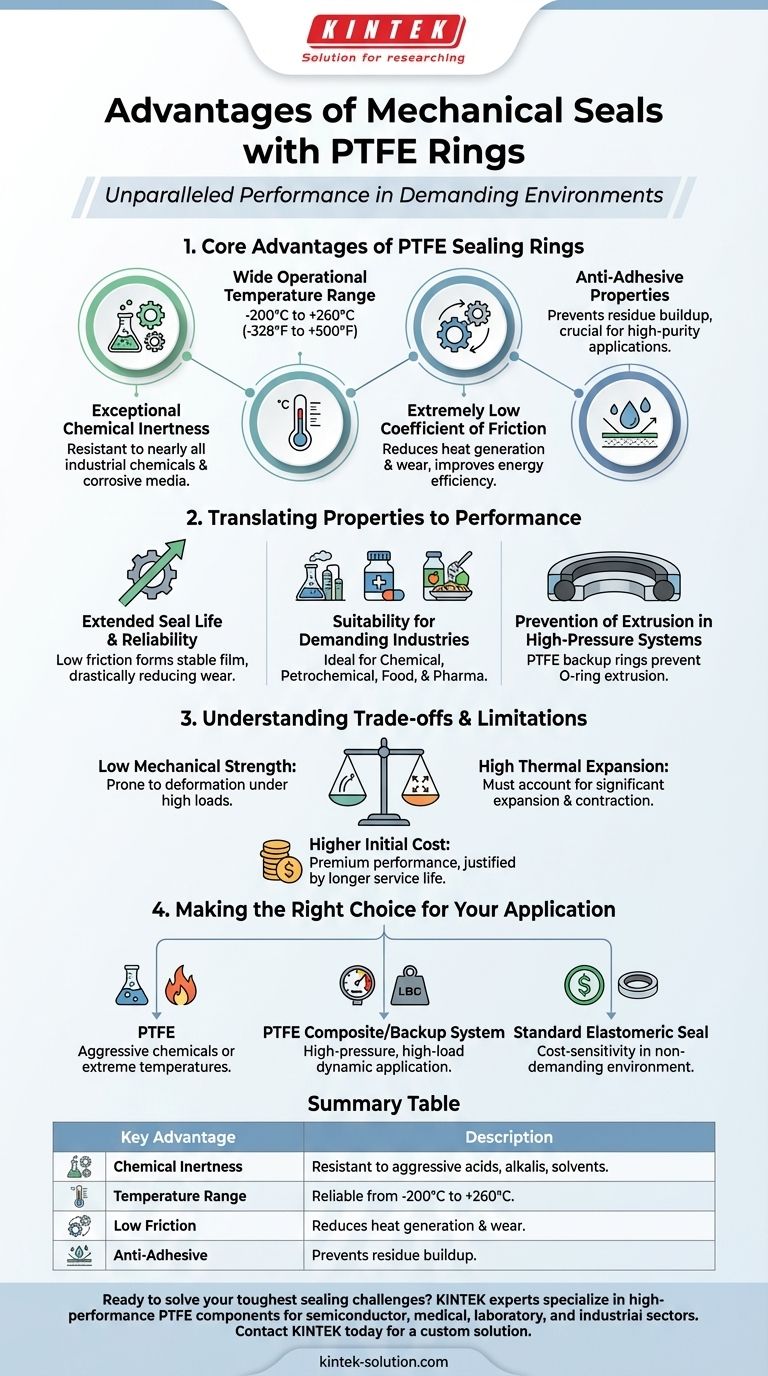

The Core Advantages of PTFE Sealing Rings

Polytetrafluoroethylene (PTFE) is a unique fluoropolymer whose molecular structure gives it a distinct set of properties highly valuable in demanding sealing applications.

Exceptional Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and corrosive media. This near-universal chemical stability ensures the seal's integrity is not compromised when handling acids, alkalis, solvents, and other aggressive substances.

Wide Operational Temperature Range

PTFE seals perform reliably across an exceptionally broad temperature spectrum, typically from –200°C to +260°C (–328°F to +500°F). This allows them to be used in cryogenic processes as well as high-temperature systems without significant degradation.

Extremely Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material. This property is critical in mechanical seals as it reduces heat generation, minimizes wear on rotating parts, and improves the overall energy efficiency of the equipment.

Anti-Adhesive Properties

The non-stick nature of PTFE prevents process media from adhering to the seal faces. This is crucial for preventing residue buildup, which can compromise seal performance and lead to premature failure, especially in food, pharmaceutical, or high-purity applications.

How These Properties Translate to Performance

The inherent advantages of PTFE directly result in superior operational performance, particularly in specialized industries.

Extended Seal Life and Reliability

The combination of low friction and chemical resistance creates a durable sealing solution. The low friction helps form a stable lubricating film between seal faces, drastically reducing wear and extending the operational life of the seal.

Suitability for Demanding Industries

Due to their properties, PTFE seals are indispensable in the chemical and petrochemical industries for handling aggressive media. Their physiological neutrality and non-stick surface also make them ideal for the food and pharmaceutical sectors, where purity is paramount.

Prevention of Extrusion in High-Pressure Systems

While PTFE itself can be a primary sealing element, it is also commonly used as a backup ring in conjunction with elastomeric O-rings. In high-pressure scenarios, PTFE backup rings prevent the softer O-ring from being extruded into clearance gaps, which is a common failure mode.

Understanding the Trade-offs and Limitations

No material is perfect. To make an informed decision, it is critical to understand the mechanical limitations of PTFE.

Low Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. It can be prone to deformation or "creep" under high mechanical loads, which makes it unsuitable for certain high-pressure or high dynamic load applications without proper engineering support, like fillers or backup rings.

High Coefficient of Thermal Expansion

PTFE expands and contracts more significantly with temperature changes than many other sealing materials. This thermal expansion must be accounted for in the seal design to ensure a consistent and effective seal across the entire operating temperature range.

Higher Initial Cost

PTFE is a premium performance material, and its initial cost is typically higher than that of standard elastomeric seals. This cost, however, is often justified by longer service life and reduced downtime in demanding applications.

Making the Right Choice for Your Application

Selecting the correct seal material depends entirely on the specific demands of your system.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is an outstanding choice due to its near-universal chemical inertness and wide temperature stability.

- If your primary focus is a high-pressure, high-load dynamic application: Pure PTFE may not be suitable, but a PTFE composite or a system using PTFE backup rings could provide the necessary performance.

- If your primary focus is cost-sensitivity in a non-demanding environment: A standard elastomeric seal may be a more economical and perfectly adequate solution.

Ultimately, choosing a PTFE sealing solution is an investment in reliability for applications where other materials simply cannot perform.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resistant to nearly all aggressive acids, alkalis, and solvents. |

| Temperature Range | Performs reliably from -200°C to +260°C (-328°F to +500°F). |

| Low Friction | Reduces heat generation and wear, improving energy efficiency. |

| Anti-Adhesive | Non-stick surface prevents residue buildup for high-purity applications. |

Ready to solve your toughest sealing challenges?

PTFE seals are critical for reliability in demanding environments. The experts at KINTEK specialize in manufacturing high-performance, precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production to ensure your seals meet exact specifications for chemical resistance, temperature stability, and longevity.

Contact KINTEB today to discuss your application and get a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability