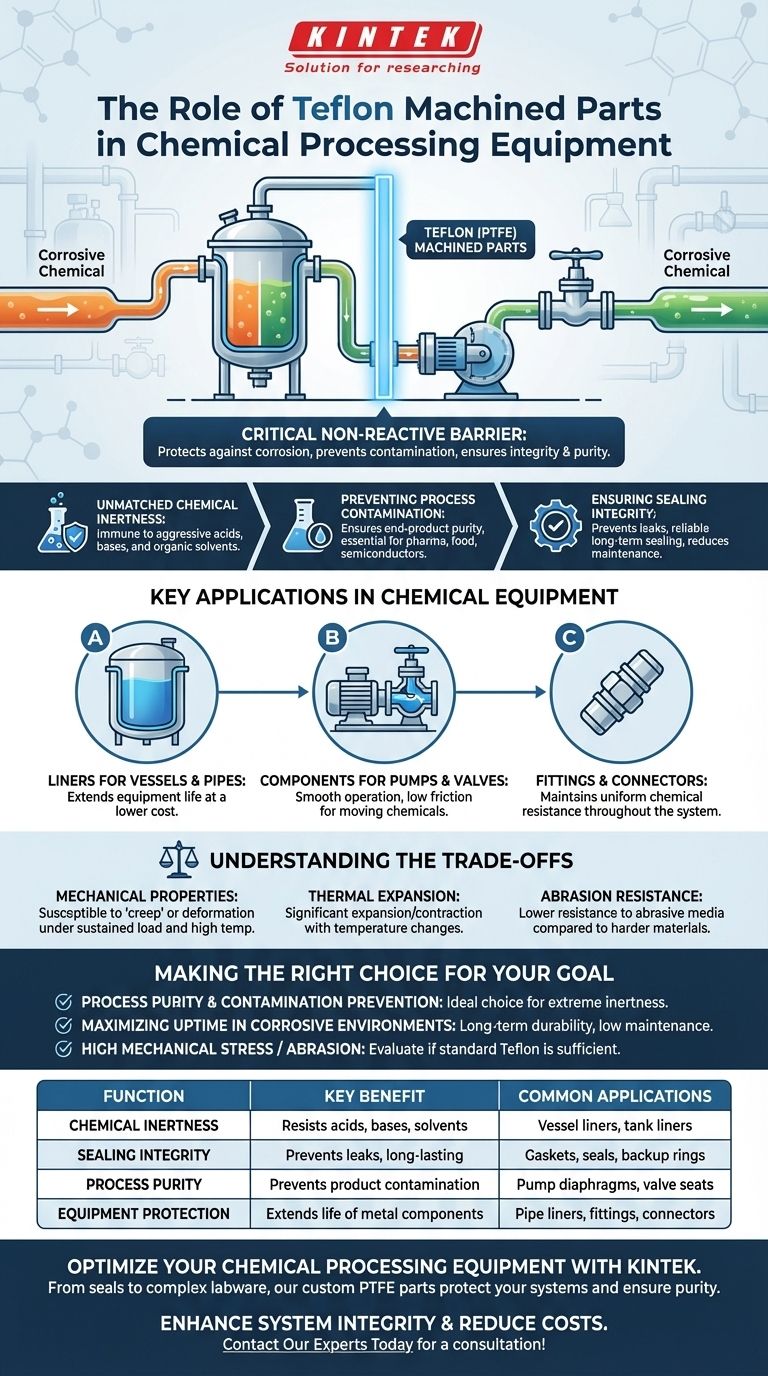

In chemical processing equipment, Teflon (PTFE) machined parts serve as a critical, non-reactive barrier, protecting system components from corrosion and preventing contamination of the chemicals being processed. Their primary role is to ensure the integrity, longevity, and purity of operations that involve aggressive acids, solvents, or other reactive substances.

The core function of Teflon in chemical processing is not merely to be a component, but to act as a strategic material choice that isolates sensitive equipment from corrosive media, thereby reducing maintenance costs and ensuring product quality.

The Core Function: A Barrier Against Chemical Attack

The value of Teflon stems from its unique molecular structure, which makes it one of the most chemically inert materials known. This property is the foundation for its use in demanding industrial environments.

Unmatched Chemical Inertness

Teflon is virtually immune to attack from the vast majority of industrial chemicals, including highly corrosive acids, bases, and organic solvents. This prevents the material itself from degrading, which is the primary cause of failure for less-resistant materials.

Preventing Process Contamination

Because Teflon does not react with or leach into the chemicals it contacts, it ensures the purity of the end product. This is critical in industries like pharmaceuticals, semiconductors, and food processing, where even trace amounts of contamination can ruin a batch.

Ensuring Sealing Integrity

In applications like backup rings, gaskets, and seals, Teflon’s chemical resistance prevents the sealing element from being eaten away. This ensures a reliable, long-lasting seal that prevents dangerous leaks and protects the system.

Key Applications in Chemical Equipment

Teflon is not a single-use solution; it is machined into various forms to solve specific problems throughout a chemical processing system. Its versatility allows it to be integrated at nearly every stage.

Liners for Vessels and Pipes

Large tanks, reactors, and pipes are often lined with a layer of Teflon. This protects the structural metal (like steel) from the corrosive contents, extending the life of major capital equipment at a fraction of the cost of building it entirely from exotic alloys.

Components for Pumps and Valves

Internal parts of pumps and valves, such as diaphragms, seats, and plugs, are frequently machined from Teflon. These components are in constant contact with moving chemicals, and Teflon’s low-friction and non-reactive properties ensure they operate smoothly without degrading.

Fittings and Connectors

Even small components like fittings can be a major point of failure if they corrode. Using Teflon for these parts ensures every point in the fluid path maintains the same high level of chemical resistance, preventing weak links in the system.

Understanding the Trade-offs

While its chemical properties are exceptional, Teflon is not a universal solution. An objective assessment requires understanding its limitations.

Mechanical Properties

Teflon is a relatively soft material and can be susceptible to "creep" or deformation under sustained load, especially at higher temperatures. It does not possess the structural strength of metals.

Thermal Expansion

Teflon has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This must be accounted for in the design of parts to avoid stress or failure when thermal cycling occurs.

Abrasion Resistance

Compared to harder plastics or metals, Teflon has lower resistance to abrasive media. It is not the ideal choice for transporting fluids containing hard, sharp particulates without proper system design.

Making the Right Choice for Your Goal

Selecting the right material is a balance of performance, safety, and cost. Teflon parts are a strategic investment where chemical compatibility is the primary concern.

- If your primary focus is process purity and preventing contamination: Teflon is an industry-standard choice due to its extreme inertness, which guarantees it will not interfere with your product.

- If your primary focus is maximizing equipment uptime in highly corrosive environments: The long-term durability and low maintenance of Teflon components provide a clear operational and financial advantage over less-resistant materials.

- If your application involves high mechanical stress or significant abrasion: You must evaluate if standard Teflon is sufficient or if a filled/reinforced grade or an entirely different material is necessary.

Ultimately, specifying Teflon machined parts is a decision to prioritize chemical resistance and long-term reliability in your most critical processes.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Vessel liners, tank liners |

| Sealing Integrity | Prevents leaks, long-lasting | Gaskets, seals, backup rings |

| Process Purity | Prevents product contamination | Pump diaphragms, valve seats |

| Equipment Protection | Extends life of metal components | Pipe liners, fittings, connectors |

Optimize your chemical processing equipment with precision-machined Teflon components from KINTEK.

Whether you are in the semiconductor, pharmaceutical, medical, or industrial sector, our custom PTFE parts—from seals and liners to complex labware—are engineered to protect your systems from corrosive media and ensure product purity. We specialize in custom fabrication, from prototypes to high-volume production, to meet your exact specifications.

Enhance your system's integrity and reduce maintenance costs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability