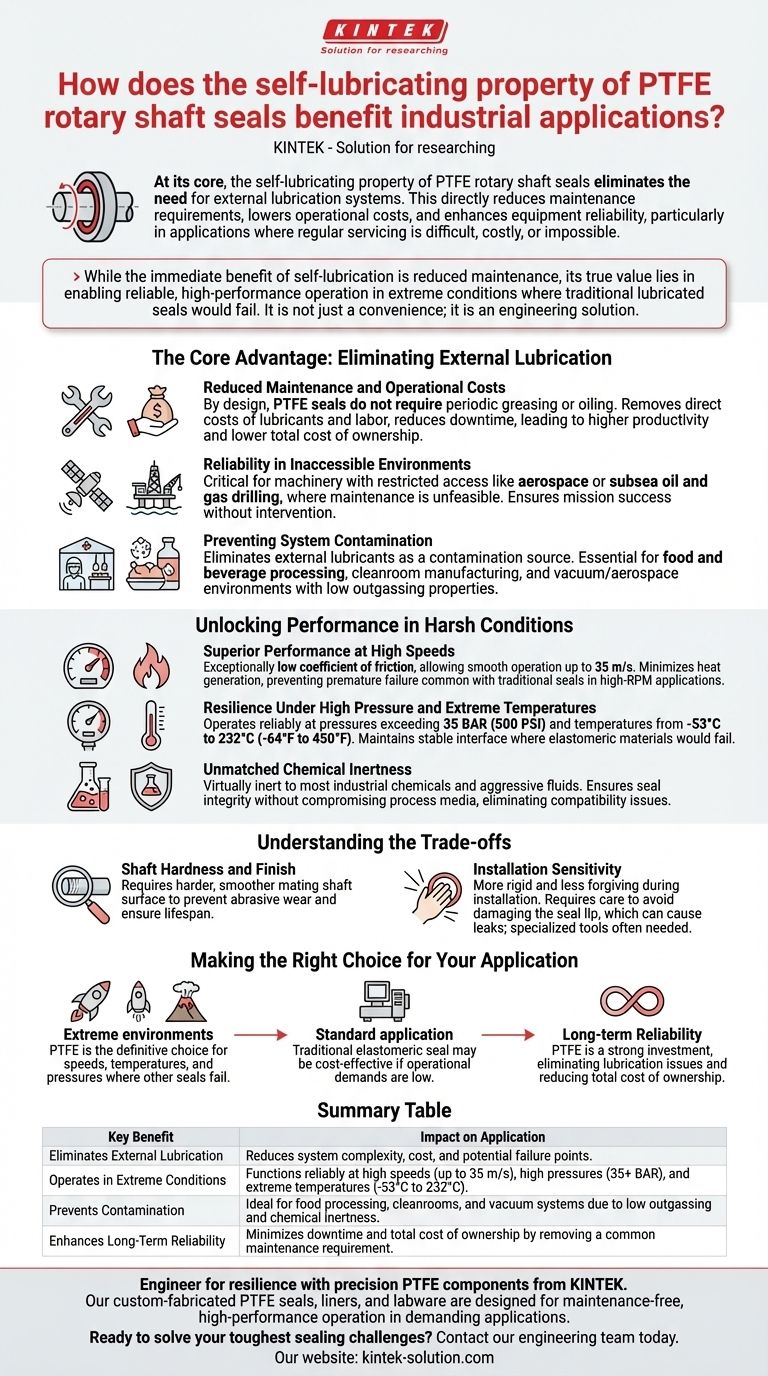

At its core, the self-lubricating property of PTFE rotary shaft seals eliminates the need for external lubrication systems. This directly reduces maintenance requirements, lowers operational costs, and enhances equipment reliability, particularly in applications where regular servicing is difficult, costly, or impossible.

While the immediate benefit of self-lubrication is reduced maintenance, its true value lies in enabling reliable, high-performance operation in extreme conditions where traditional lubricated seals would fail. It is not just a convenience; it is an engineering solution.

The Core Advantage: Eliminating External Lubrication

The most significant benefit of PTFE's self-lubricating nature is the removal of an entire system dependency. This simplifies machine design and eliminates multiple potential points of failure.

Reduced Maintenance and Operational Costs

By design, PTFE seals do not require periodic greasing or oiling. This removes the direct costs of lubricants and the labor required for application.

More importantly, it reduces equipment downtime scheduled for routine maintenance, leading to higher productivity and lower total cost of ownership.

Reliability in Inaccessible Environments

Self-lubrication is critical for machinery where access is severely restricted.

In industries like aerospace or subsea oil and gas drilling, performing maintenance on a seal is often not feasible. A PTFE seal's ability to function for its entire lifespan without intervention is essential for mission success.

Preventing System Contamination

External lubricants can themselves become a source of contamination. This is unacceptable in sensitive applications like food and beverage processing or cleanroom manufacturing.

Furthermore, in vacuum or aerospace environments, the low outgassing properties of PTFE prevent the release of volatile compounds that could contaminate sensitive optical or electronic components.

Unlocking Performance in Harsh Conditions

The self-lubricating characteristic works in concert with PTFE's other inherent properties to create a seal that excels under mechanical and chemical stress.

Superior Performance at High Speeds

PTFE has an exceptionally low coefficient of friction, allowing it to glide smoothly over rotating shafts. This minimizes heat generation, even at surface speeds up to 35 m/s.

In high-RPM applications, traditional seals can overheat, leading to material degradation and premature failure. PTFE's low-friction, self-lubricating surface effectively prevents this failure mode.

Resilience Under High Pressure and Extreme Temperatures

PTFE seals are engineered to operate reliably at pressures exceeding 35 BAR (500 PSI) and across a vast temperature range, typically from -53°C to 232°C (-64°F to 450°F).

The self-lubricating interface remains stable and effective across these extremes, ensuring a consistent seal where elastomeric materials would become brittle or degrade.

Unmatched Chemical Inertness

PTFE is virtually inert to most industrial chemicals and aggressive fluids.

This means the seal's integrity is not compromised by the process media it is sealing. It also means there is no need to find a specialized, system-wide lubricant that is compatible with both the seal and the potentially corrosive process fluid.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Acknowledging their specific requirements is key to successful implementation.

Shaft Hardness and Finish

To function correctly, the low-friction PTFE lip requires a mating shaft surface that is harder and smoother than what might be acceptable for a traditional rubber seal.

Failing to meet the specified shaft hardness and finish can lead to abrasive wear on the seal lip, compromising its lifespan and performance.

Installation Sensitivity

PTFE seals are more rigid than their elastomeric counterparts. This rigidity makes them less forgiving during installation.

Care must be taken to avoid scratching or nicking the seal lip during assembly, as any minor damage can create a significant leak path. Specialized installation tools are often required.

Making the Right Choice for Your Application

Selecting the right seal requires evaluating your specific operational demands against the material's capabilities.

- If your primary focus is extreme environments or high performance: PTFE is the definitive choice, as its self-lubricating nature enables operation at speeds, temperatures, and pressures where other seals cannot survive.

- If your primary focus is a standard, low-stress application: A traditional elastomeric seal may be more cost-effective for the initial purchase if the operational demands are well within its limits.

- If your primary focus is long-term reliability and minimal maintenance: PTFE is a strong investment, as it eliminates a common failure mode (lubrication system) and reduces the total cost of ownership over the equipment's life.

Ultimately, choosing a PTFE seal is a decision to engineer for resilience, especially when performance cannot be compromised.

Summary Table:

| Key Benefit | Impact on Application |

|---|---|

| Eliminates External Lubrication | Reduces system complexity, cost, and potential failure points. |

| Operates in Extreme Conditions | Functions reliably at high speeds (up to 35 m/s), high pressures (35+ BAR), and extreme temperatures (-53°C to 232°C). |

| Prevents Contamination | Ideal for food processing, cleanrooms, and vacuum systems due to low outgassing and chemical inertness. |

| Enhances Long-Term Reliability | Minimizes downtime and total cost of ownership by removing a common maintenance requirement. |

Engineer for resilience with precision PTFE components from KINTEK.

Our custom-fabricated PTFE seals, liners, and labware are designed to deliver maintenance-free, high-performance operation in the most demanding semiconductor, medical, laboratory, and industrial applications. We combine material expertise with precision production to ensure your equipment operates reliably, even in extreme conditions.

Ready to solve your toughest sealing challenges? Contact our engineering team today to discuss your specific requirements, from prototypes to high-volume orders.

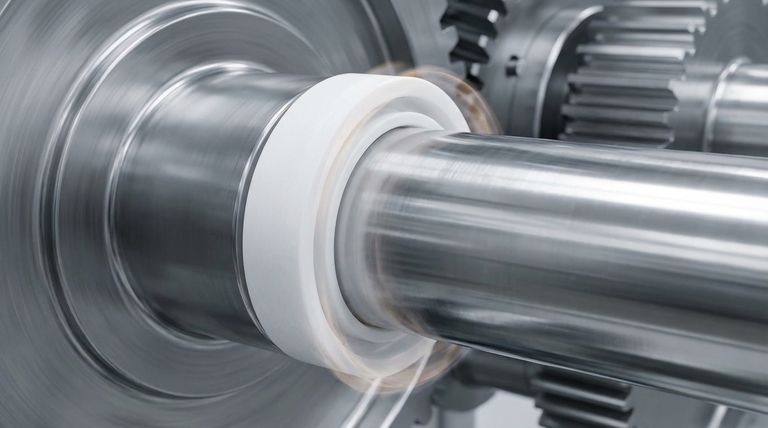

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability