The single most important property of a PTFE rotary shaft seal is its exceptionally low coefficient of friction. This characteristic is not merely a technical detail; it is the primary enabler of the seal's performance, directly translating to higher operational efficiency, significantly longer equipment life, and reduced long-term costs by minimizing energy loss and physical wear.

The core takeaway is that a PTFE seal's low friction is not just about being "slippery." It is a fundamental property that allows machinery to run faster, hotter, and with more aggressive chemicals while simultaneously reducing wear, maintenance, and the energy required to operate.

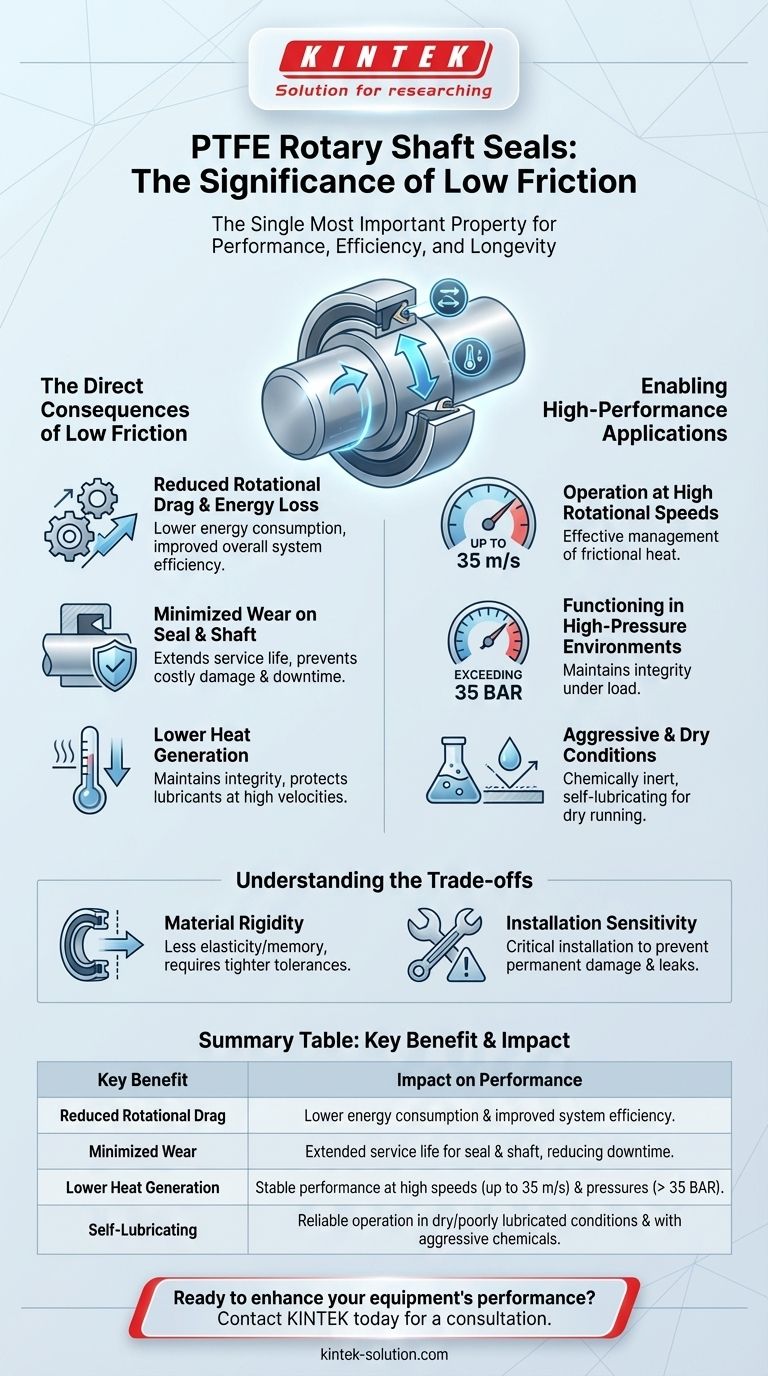

The Direct Consequences of Low Friction

The low friction coefficient of Polytetrafluoroethylene (PTFE) has several immediate and powerful effects on the performance of a rotating system. These benefits are interconnected, each amplifying the others.

Reduced Rotational Drag and Energy Loss

Friction is a direct source of resistance. By minimizing this resistance, PTFE seals allow the shaft to rotate more freely.

This translates directly into lower energy consumption for the entire system, leading to improved overall efficiency.

Minimized Wear on the Seal and Shaft

The primary cause of failure in a dynamic seal is physical wear. The low-friction nature of PTFE drastically reduces the abrasive forces between the seal lip and the rotating shaft surface.

This mutual protection extends the service life of both the seal and the shaft, preventing costly damage and downtime.

Lower Heat Generation

Friction generates heat. In a high-speed rotary application, this heat can become extreme, leading to the breakdown of lubricants and the degradation of seal materials.

Because PTFE generates very little frictional heat, it maintains its integrity and protects lubricants, ensuring stable performance even at high velocities.

How Low Friction Enables High-Performance Applications

The physical benefits of low friction allow PTFE seals to operate reliably in conditions where traditional elastomeric seals would quickly fail. This makes them essential in demanding industries like aerospace, oil and gas, and chemical processing.

Operation at High Rotational Speeds

The ability to manage heat generation is the limiting factor for seal performance at high speeds. PTFE's low friction allows it to operate effectively at surface velocities up to 35 m/s.

Functioning in High-Pressure Environments

While other material properties contribute, low friction helps the seal maintain its integrity under load. PTFE seals can reliably perform in systems with pressures exceeding 35 BAR.

Suitability for Aggressive and Dry Conditions

PTFE is chemically inert, making it compatible with nearly all industrial fluids and lubricants.

Furthermore, its self-lubricating properties mean it can perform exceptionally well even in dry-running or poorly lubricated applications where other seals would fail from excessive friction and wear.

Understanding the Trade-offs

While its low friction provides immense benefits, PTFE is not a universal solution. Understanding its unique material properties is key to successful implementation.

Material Rigidity

Compared to traditional rubber or elastomer seals, PTFE is a much more rigid polymer. It has less elasticity and "memory."

This means it is less forgiving of imperfections in the shaft or housing, requiring tighter tolerances for optimal performance.

Installation Sensitivity

The rigidity of PTFE seals makes proper installation critical. Unlike a flexible rubber seal that can be stretched into place, a PTFE seal can be easily damaged if not installed with the correct tools and procedures.

Scratches or deformation during installation can create a permanent leak path, compromising the seal's function from the start.

Making the Right Choice for Your Application

Selecting a seal material should be driven by the specific demands of your operating environment. The significance of PTFE's low friction becomes clear when viewed through the lens of your primary goal.

- If your primary focus is high-speed or high-pressure operation: PTFE's low friction is non-negotiable, as it is the key to managing the extreme heat and wear generated in these conditions.

- If your primary focus is chemical compatibility: While its low friction is a major benefit, PTFE's chemical inertness is the principal reason for its selection in aggressive environments.

- If your primary focus is minimizing long-term costs: The extended service life, reduced maintenance, and lower energy consumption driven by low friction offer a compelling total cost of ownership.

Ultimately, leveraging the low friction of a PTFE seal allows you to design and operate more efficient, powerful, and reliable mechanical systems.

Summary Table:

| Key Benefit | Impact on Performance |

|---|---|

| Reduced Rotational Drag | Lower energy consumption and improved system efficiency. |

| Minimized Wear | Extended service life for both the seal and the shaft, reducing downtime. |

| Lower Heat Generation | Stable performance at high speeds (up to 35 m/s) and pressures (exceeding 35 BAR). |

| Self-Lubricating | Reliable operation in dry or poorly lubricated conditions and with aggressive chemicals. |

Ready to enhance your equipment's performance with the superior properties of PTFE seals?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom rotary shaft seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal perfectly tailored to your application's speed, pressure, and chemical requirements.

Leverage our precision production to reduce energy loss, minimize wear, and extend the life of your machinery. Contact KINTEK today for a consultation and let our experts help you solve your most challenging sealing problems.

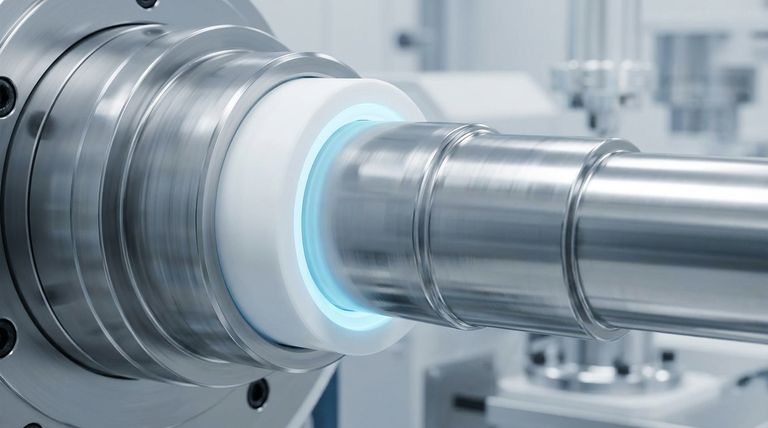

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- In what industries are Teflon lip seals commonly used? Essential for Extreme Chemical & Temperature Resistance

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- What are the properties of 10% PEEK-filled PTFE bushings? Enhance Wear Resistance & High-Temp Performance

- How do fillers improve the properties of PTFE? Boost Wear Resistance, Creep Resistance & Thermal Conductivity

- What other factors influence the CNC machining quality of PTFE parts? Master Material, Environment & Skill

- What are the key technical features of PTFE tri clamp gaskets? Unmatched Chemical & Thermal Resistance

- How can users obtain customized PTFE gaskets and sheets? Get Precision Parts for Your Industry

- What are the electrical insulation properties of PTFE caps? Superior Dielectric Performance for Demanding Applications