At a technical level, PTFE tri-clamp gaskets are defined by their exceptional chemical inertness and wide temperature tolerance. This unique combination makes them a superior choice for sterile processing environments involving aggressive media. Key features include an operational temperature range from -73°C to 260°C (-100°F to 500°F), near-universal chemical resistance, FDA compliance, and a non-stick, low-friction surface that ensures purity and longevity.

The central trade-off with PTFE is simple: you gain elite chemical and thermal resistance but sacrifice the mechanical forgiveness found in common elastomers. Understanding this balance is critical to using them effectively.

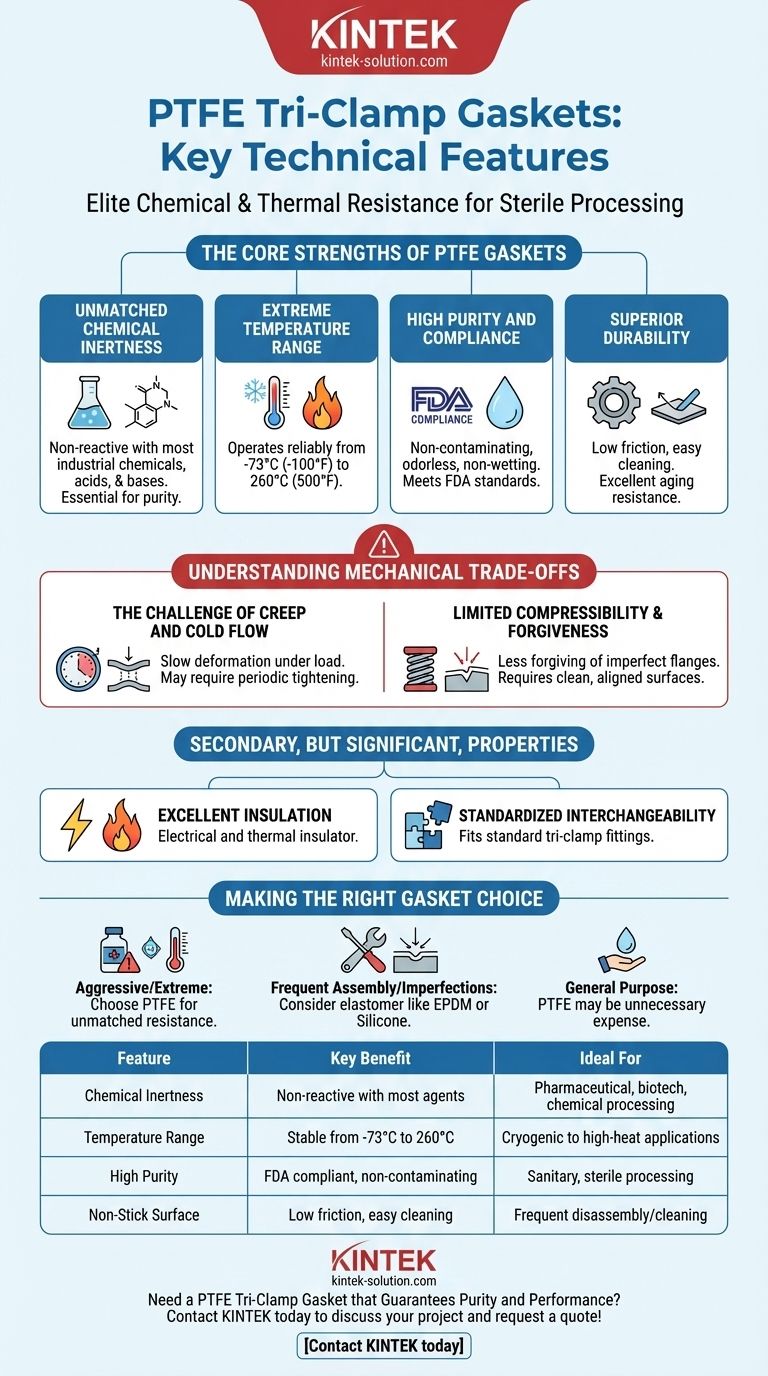

The Core Strengths of PTFE Gaskets

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer, and its inherent properties translate directly into the gaskets' primary advantages.

Unmatched Chemical Inertness

PTFE is non-reactive with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for pharmaceutical, biotech, and chemical processing where product purity is non-negotiable.

Unlike elastomers that can swell, degrade, or leach extractables, PTFE remains stable, ensuring it does not contaminate the process media.

Extreme Temperature Range

These gaskets operate reliably in a very broad temperature window, from cryogenic lows of -73°C (-100°F) up to sustained highs of 260°C (500°F).

This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures, a common failure point for gaskets made from silicone or EPDM.

High Purity and Compliance

PTFE is an inherently pure material that is non-contaminating, odorless, and non-wetting. These properties make it easy to clean and sterilize.

Virgin PTFE meets FDA standards for food and pharmaceutical contact, making it a default choice for sanitary tri-clamp applications where process integrity is paramount.

Superior Durability and Surface Properties

PTFE exhibits a very low coefficient of friction, creating a non-stick surface. This reduces wear during assembly and makes disassembly and cleaning significantly easier.

This material also has excellent aging resistance, meaning it does not degrade from exposure to UV light or weather, contributing to a longer service life compared to many elastomers.

Understanding the Mechanical Trade-offs

The immense chemical and thermal stability of PTFE comes at the cost of its mechanical properties. These limitations are crucial to understand for successful implementation.

The Challenge of Creep and Cold Flow

PTFE is susceptible to creep, which is the tendency of the material to slowly deform over time when under a constant compressive load (like a tightened clamp).

This phenomenon, also known as cold flow, can cause the seal to loosen over time, especially in systems with temperature or pressure cycles. It often necessitates periodic retightening of clamps.

Limited Compressibility and Forgiveness

Compared to rubber-like materials, PTFE is relatively rigid and has limited compressibility. It does not conform easily to minor imperfections, scratches, or misalignments in flange faces.

For a reliable seal, PTFE gaskets require clean, smooth, and perfectly aligned flange surfaces. They are less forgiving of imperfect connections than a more flexible EPDM or silicone gasket would be.

Secondary, But Significant, Properties

Beyond the primary features, two other technical aspects are relevant for specific applications.

Excellent Electrical and Thermal Insulation

In its virgin form, PTFE is an exceptional electrical insulator, making it useful in applications where electrical isolation is required.

It also serves as a good thermal insulator, which can be a factor in maintaining stable process temperatures across a connection point.

Standardized Interchangeability

PTFE tri-clamp gaskets are manufactured to standard industry sizes. This ensures they are fully interchangeable with any standard tri-clamp or tri-clover fitting, allowing for easy upgrades or replacements in existing systems.

Making the Right Gasket Choice

Your application's specific demands should dictate your material choice.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is almost certainly the correct technical choice due to its unmatched resistance.

- If your primary focus is frequent assembly/disassembly or you have older, slightly imperfect flange surfaces: You should carefully consider a more forgiving elastomer like EPDM or silicone, provided it is compatible with your process media.

- If your primary focus is a general-purpose application without chemical or thermal extremes: PTFE may be an unnecessary expense, and other materials can provide a reliable seal more cost-effectively.

Ultimately, choosing a PTFE gasket is a decision to prioritize chemical purity and thermal stability above all else.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Non-reactive with most acids, bases, and solvents | Pharmaceutical, biotech, chemical processing |

| Temperature Range | Stable from -73°C to 260°C (-100°F to 500°F) | Cryogenic to high-heat applications |

| High Purity | FDA compliant, non-contaminating, easy to sterilize | Sanitary, sterile processing environments |

| Non-Stick Surface | Low friction, easy cleaning, excellent aging resistance | Applications requiring frequent disassembly and cleaning |

Need a PTFE Tri-Clamp Gasket that Guarantees Purity and Performance?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your gaskets deliver unmatched chemical resistance and thermal stability, protecting your critical processes.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications. Let us provide the reliable, high-performance sealing solution your application demands.

Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability