Getting custom PTFE gaskets and sheets is a straightforward process. Thanks to modern manufacturing and online accessibility, users can order these materials directly from fabricators by providing a detailed list of specifications. This allows for the creation of components precisely tailored to meet unique industrial and engineering requirements.

The key to successful PTFE customization isn't just knowing you can change the size and shape. It's understanding how to specify the right material properties—like fillers, thickness, and form—to solve your specific engineering challenge effectively.

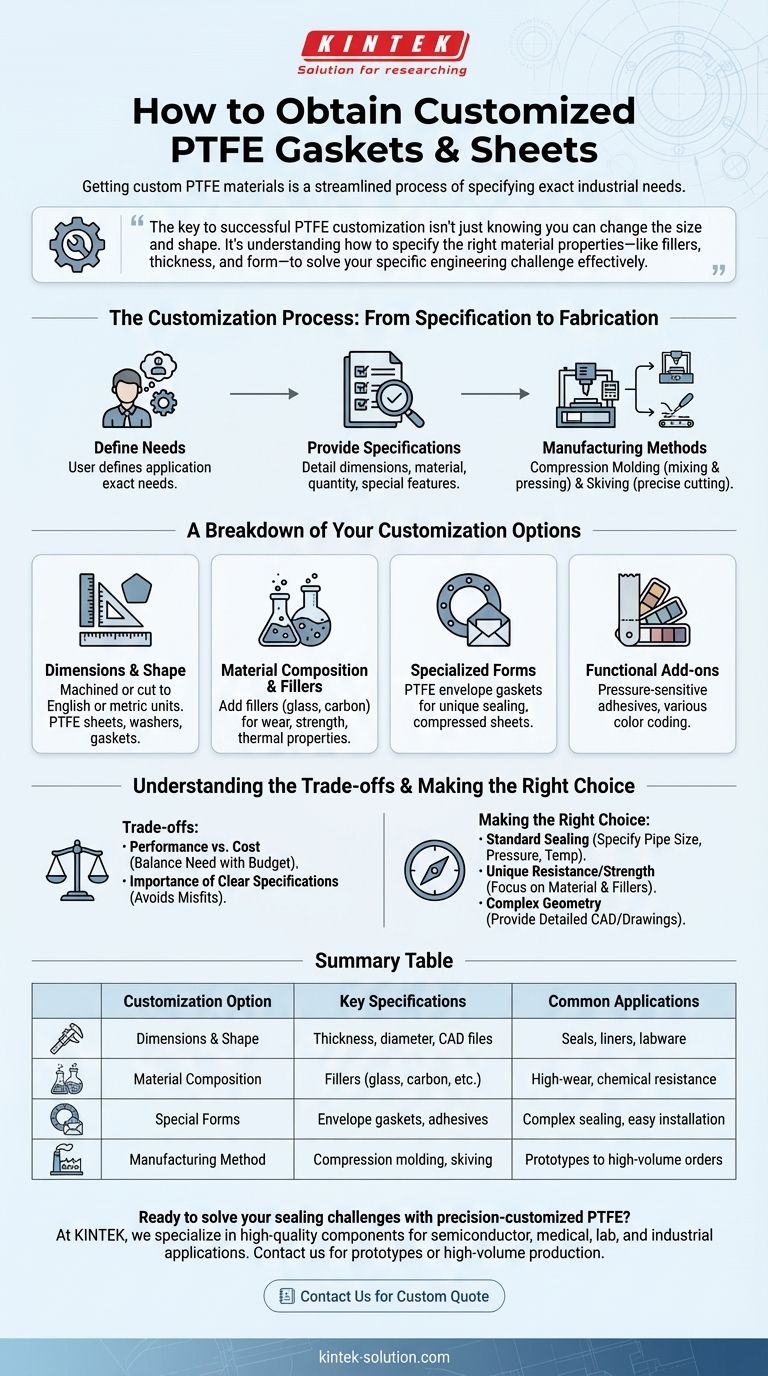

The Customization Process: From Specification to Fabrication

The process begins with you, the user, defining the exact needs of your application. The manufacturer then uses this information to create the final product.

Providing Your Specifications

The first and most critical step is providing the manufacturer with clear and detailed requirements. This includes dimensions, material grade, quantity, and any special features needed for your application.

Key Manufacturing Methods

Manufacturers typically use two primary methods to create custom parts. Compression molding involves mixing PTFE powder with a lubricant, pressing it into a preform, and then heating and compressing it into a solid shape. Skiving is a process where thin sheets are precisely cut from a larger block of PTFE to create gaskets or other flat profiles.

A Breakdown of Your Customization Options

PTFE's versatility allows for a wide range of modifications. Understanding these options is crucial for getting a part that performs optimally.

Dimensions and Shape

The most common customization is size and shape. PTFE sheets, washers, and gaskets can be machined or cut to virtually any specification, with dimensions provided in either English or metric units.

Material Composition and Fillers

Pure PTFE can be modified with various fillers to enhance specific properties like wear resistance, compressive strength, or thermal conductivity. You can specify a composition that best matches your operational demands.

Specialized Forms

Beyond simple sheets, you can order specialized forms. PTFE envelope gaskets, for example, can be custom-made for unique sealing challenges, while compressed sheets offer different performance characteristics.

Functional Add-ons

Further customization can include practical features. For instance, pressure-sensitive adhesives can be pre-applied to washers and gaskets for easier installation, and parts can be ordered in various colors for coding or identification.

Understanding the Trade-offs

While customization offers significant advantages, it's important to approach it with a clear understanding of the implications.

Performance vs. Cost

Customization allows you to create a perfect-fit solution, but this can come at a higher price. More complex geometries, tighter tolerances, or specialized fillers will influence the final cost. The goal is to balance operational need with budget.

The Importance of Clear Specifications

The quality of the final product depends entirely on the quality of the information you provide. Ambiguous or incomplete specifications can result in parts that don't fit or perform as expected. The responsibility for providing accurate details rests with you.

Making the Right Choice for Your Goal

To ensure you get the right product, align your specifications with your primary objective.

- If your primary focus is standard sealing: Specify the pipe size, pressure, and temperature, and a manufacturer can recommend a suitable gasket with minimal modification.

- If your primary focus is unique chemical resistance or mechanical strength: Concentrate your specifications on the material composition, including the type of filler required for your specific application.

- If your primary focus is complex geometry or a non-standard fit: Provide a detailed engineering drawing or CAD file to ensure the machined part meets your exact dimensional requirements.

By clearly defining your operational needs, you can leverage the versatility of PTFE customization to achieve an optimal and cost-effective solution.

Summary Table:

| Customization Option | Key Specifications | Common Applications |

|---|---|---|

| Dimensions & Shape | Thickness, diameter, CAD files | Seals, liners, labware |

| Material Composition | Fillers (glass, carbon, etc.) | High-wear, chemical resistance |

| Special Forms | Envelope gaskets, adhesives | Complex sealing, easy installation |

| Manufacturing Method | Compression molding, skiving | Prototypes to high-volume orders |

Ready to solve your sealing or component challenges with precision-customized PTFE?

At KINTEK, we specialize in manufacturing high-quality PTFE components—including seals, liners, gaskets, and labware—for semiconductor, medical, laboratory, and industrial applications. Whether you need prototypes or high-volume production, we deliver tailored solutions that meet your exact specifications for performance, durability, and cost-effectiveness.

Contact us today to discuss your project and get a custom quote!

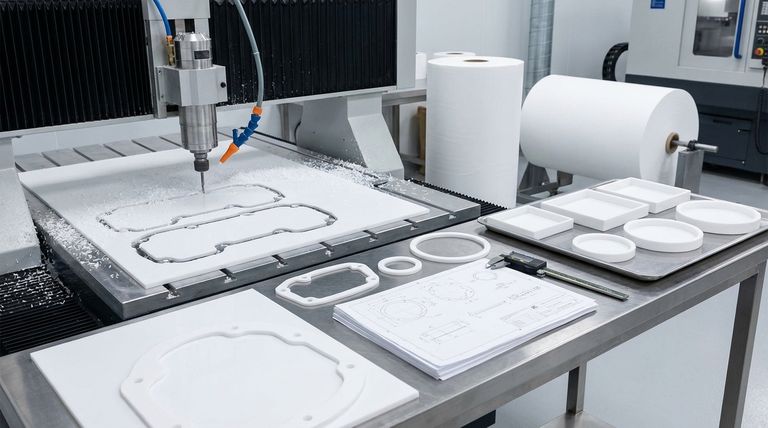

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications