In short, Teflon (PTFE) lip seals are used across nearly every demanding industrial sector. Their primary applications are in chemical processing, oil and gas, food and beverage, pharmaceutical, automotive, and aerospace industries where standard seals would quickly fail.

The widespread use of Teflon lip seals is not a matter of preference but a necessity. They are the go-to solution for any application involving extreme temperatures, aggressive chemicals, high speeds, or stringent purity requirements.

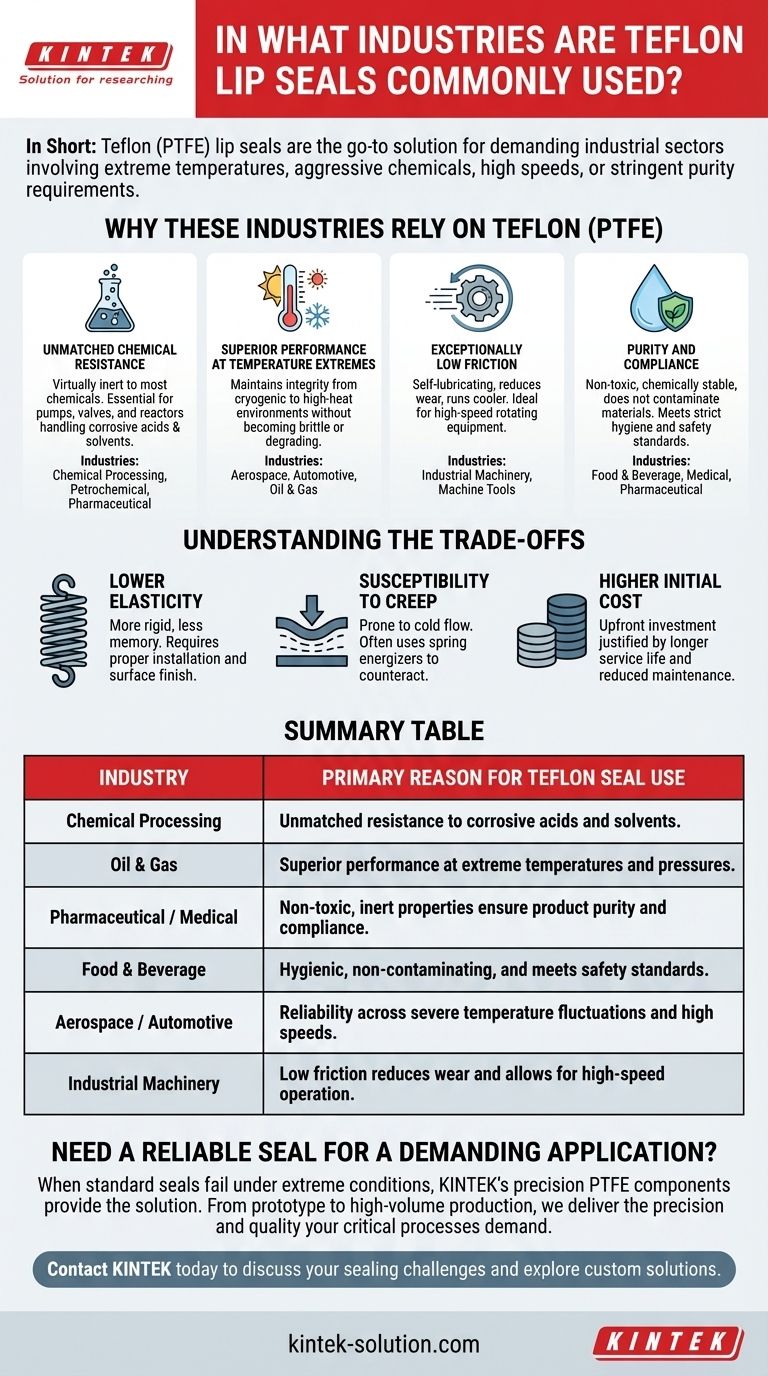

Why These Industries Rely on Teflon (PTFE)

The adoption of Teflon seals is driven by a unique combination of material properties that solve critical engineering challenges. Standard rubber or elastomeric seals simply cannot perform reliably under the conditions where PTFE excels.

Unmatched Chemical Resistance

Teflon is virtually inert, meaning it does not react with most chemicals. This makes it essential for equipment that handles corrosive acids, solvents, and other aggressive compounds.

This property is the primary reason for its dominance in the chemical processing, petrochemical, and pharmaceutical industries for sealing pumps, valves, and reactors.

Superior Performance at Temperature Extremes

PTFE seals maintain their integrity and sealing capability across an exceptionally wide temperature range. They do not become brittle in cryogenic conditions or degrade in high-heat environments.

This makes them indispensable in aerospace, automotive, and oil and gas applications, where components must endure severe operational temperature fluctuations.

Exceptionally Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is critical in high-speed rotating equipment.

It allows seals to run cooler, reduce wear on shafts, and even perform in dry or abrasive environments, making them ideal for industrial machinery and machine tools.

Purity and Compliance

Because PTFE is non-toxic and chemically stable, it does not contaminate the materials it comes into contact with. This is a non-negotiable requirement for certain sectors.

The food and beverage, medical, and pharmaceutical industries rely on Teflon seals to meet strict hygiene and safety compliance standards for their processing and packaging equipment.

Understanding the Trade-offs

While highly effective, Teflon seals are not a universal solution. Understanding their limitations is key to using them correctly.

Lower Elasticity

Compared to rubber seals, PTFE is a much more rigid material. It has less "memory" and is less forgiving of imperfections on a shaft or housing surface.

Proper installation and surface finish are critical to prevent leaks, as the seal is less able to conform to irregularities.

Susceptibility to Creep

Under sustained pressure and temperature, PTFE can be prone to "cold flow" or creep, where the material slowly deforms over time.

Seal design often incorporates spring energizers or specialized fillers in the PTFE blend to counteract this effect and maintain a consistent sealing force.

Higher Initial Cost

Teflon lip seals typically have a higher upfront cost than their standard elastomeric counterparts.

However, this cost is often justified by significantly longer service life, reduced maintenance, and the prevention of costly failures in critical applications.

Making the Right Choice for Your Goal

Selecting a seal requires matching its properties to the demands of the operating environment.

- If your primary focus is resisting aggressive chemicals: Teflon is the default choice, offering unparalleled protection against corrosive media.

- If your primary focus is operating at extreme temperatures: PTFE's stability across a vast temperature range makes it a superior choice over most elastomers.

- If your primary focus is minimizing friction in high-speed machinery: The self-lubricating nature of Teflon reduces wear and energy consumption.

- If your primary focus is ensuring absolute purity: Teflon's inert and non-toxic properties are essential for food, medical, and pharmaceutical compliance.

Ultimately, choosing a Teflon seal is an investment in reliability for environments where failure is not an option.

Summary Table:

| Industry | Primary Reason for Teflon Seal Use |

|---|---|

| Chemical Processing | Unmatched resistance to corrosive acids and solvents |

| Oil & Gas | Superior performance at extreme temperatures and pressures |

| Pharmaceutical / Medical | Non-toxic, inert properties ensure product purity and compliance |

| Food & Beverage | Hygienic, non-contaminating, and meets safety standards |

| Aerospace / Automotive | Reliability across severe temperature fluctuations and high speeds |

| Industrial Machinery | Low friction reduces wear and allows for high-speed operation |

Need a reliable seal for a demanding application?

When standard seals fail under extreme temperatures, aggressive chemicals, or stringent purity requirements, KINTEK's precision PTFE components provide the solution. We manufacture high-performance Teflon lip seals, custom-designed to meet the specific challenges of your industry—from semiconductor and medical to laboratory and industrial applications.

Our expertise ensures your equipment operates reliably, reducing downtime and preventing costly failures. From prototype to high-volume production, we deliver the precision and quality your critical processes demand.

Contact KINTEK today to discuss your sealing challenges and explore custom solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers