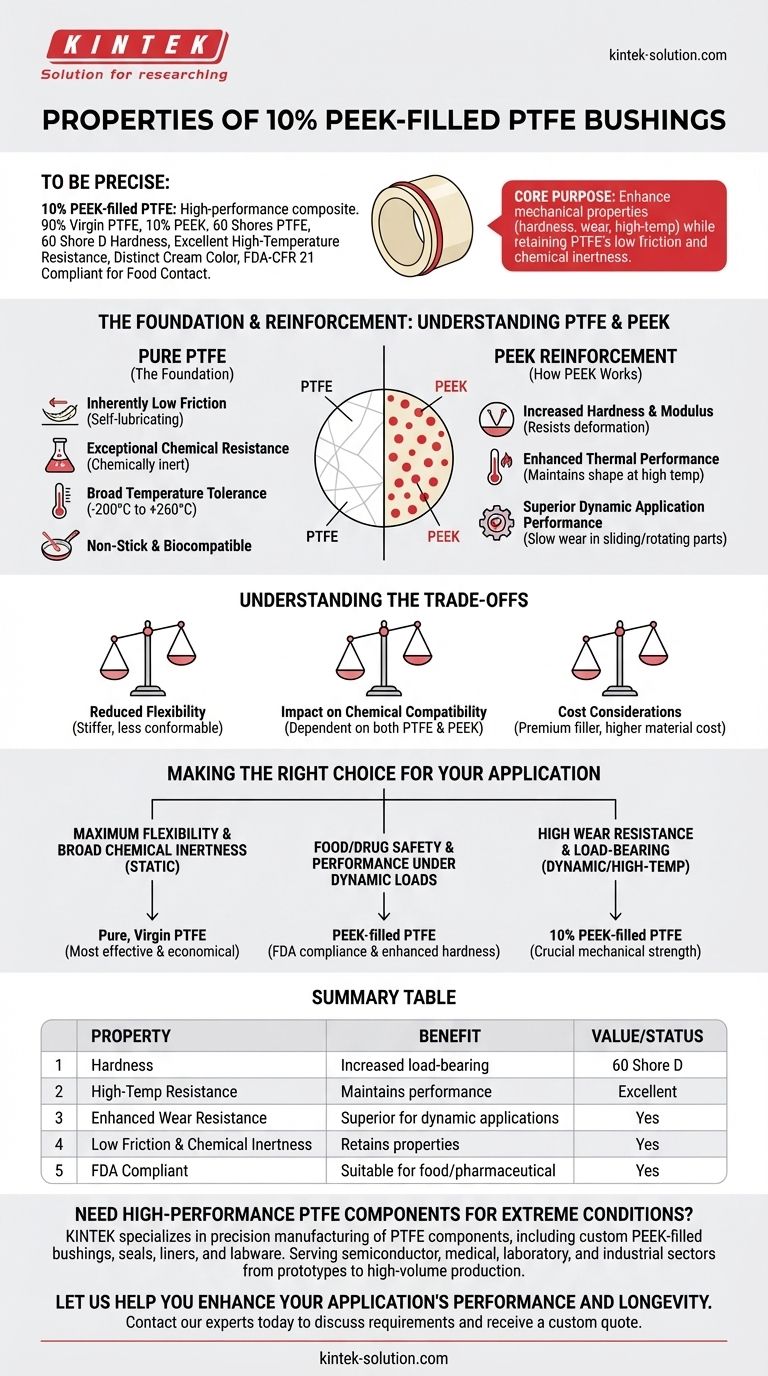

To be precise, 10% PEEK-filled PTFE is a high-performance composite material combining 90% virgin Polytetrafluoroethylene (PTFE) with 10% Polyetheretherketone (PEEK). This blend results in a high modulus material with a hardness of 60 Shore D, excellent high-temperature resistance, and a distinct cream color. It is often used for demanding applications like back-up rings and is compliant with FDA-CFR 21 standards for food contact.

The core purpose of adding 10% PEEK to PTFE is to significantly enhance its mechanical properties—specifically hardness, wear resistance, and high-temperature performance—while retaining PTFE's fundamental benefits of low friction and chemical inertness.

The Foundation: Understanding Pure PTFE

To appreciate the PEEK-filled variant, we must first understand the base material. Pure PTFE is a remarkable polymer known for a unique combination of properties.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This allows for self-lubricating performance, eliminating the need for external lubricants and preventing stick-slip issues in moving parts.

Exceptional Chemical Resistance

The material is chemically inert and insoluble, making it highly resistant to a vast range of chemicals and moisture. This property is critical for applications in corrosive environments.

Broad Temperature Tolerance

Virgin PTFE operates reliably across a huge temperature range, typically from -200°C to +260°C (-328°F to +500°F), without significant degradation.

Non-Stick and Biocompatible

Its non-adhesive surface prevents contamination and simplifies cleaning. Because it is chemically unreactive and non-toxic, it is suitable for use in food, pharmaceutical, and medical applications.

How PEEK Reinforces the PTFE Matrix

While pure PTFE is excellent, it is also relatively soft and can deform under load (a phenomenon known as "cold flow"). Adding a high-performance filler like PEEK directly addresses these mechanical limitations.

Increased Hardness and Modulus

PEEK is a much harder, more rigid polymer than PTFE. Blending it into the PTFE matrix significantly increases the composite's surface hardness and stiffness, allowing it to withstand higher loads and resist deformation.

Enhanced Thermal Performance

The addition of PEEK improves the material's thermal resistance. This means the bushing maintains its shape and strength better at elevated temperatures, especially under mechanical stress.

Superior Dynamic Application Performance

The increased hardness and wear resistance make PEEK-filled PTFE far superior to pure PTFE in dynamic applications involving sliding or rotating parts. It wears down much more slowly, extending the service life of the component.

Understanding the Trade-offs

No material choice is without compromise. Acknowledging the trade-offs is key to making an informed engineering decision.

Reduced Flexibility

Pure PTFE is known for its flexibility. The addition of a rigid filler like PEEK makes the resulting composite stiffer and less conformable. This must be considered for applications requiring sealing or fitting over complex geometries.

Impact on Chemical Compatibility

While the overall chemical resistance remains excellent, it is now dependent on the properties of both PTFE and PEEK. For extremely aggressive or unusual chemical environments, the compatibility of PEEK must also be verified.

Cost Considerations

PEEK is a premium, high-performance polymer. Introducing it as a filler will invariably increase the material cost compared to unfilled, virgin PTFE or PTFE with less expensive fillers.

Making the Right Choice for Your Application

Selecting the correct material depends entirely on the specific demands of your operating environment.

- If your primary focus is maximum flexibility and broad chemical inertness in a static application: Pure, virgin PTFE is often the most effective and economical choice.

- If your primary focus is high wear resistance and load-bearing capability, especially at elevated temperatures: 10% PEEK-filled PTFE provides the crucial mechanical strength that pure PTFE lacks.

- If your application requires food or drug safety combined with performance under dynamic loads: The FDA compliance and enhanced hardness of this specific blend make it an ideal candidate.

Ultimately, choosing 10% PEEK-filled PTFE is a deliberate decision to upgrade the mechanical integrity of a component for more demanding service conditions.

Summary Table:

| Property | Benefit |

|---|---|

| Hardness (60 Shore D) | Increased load-bearing capacity & resistance to deformation |

| High-Temp Resistance | Maintains performance at elevated temperatures |

| Enhanced Wear Resistance | Superior for dynamic applications with sliding/rotating parts |

| Low Friction & Chemical Inertness | Retains PTFE's self-lubricating and corrosion-resistant properties |

| FDA Compliant | Suitable for food, pharmaceutical, and medical applications |

Need high-performance PTFE components that can handle extreme conditions?

KINTEK specializes in precision manufacturing of PTFE components, including custom PEEK-filled bushings, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume production.

Let us help you enhance your application's performance and longevity. Contact our experts today to discuss your specific requirements and receive a custom quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability