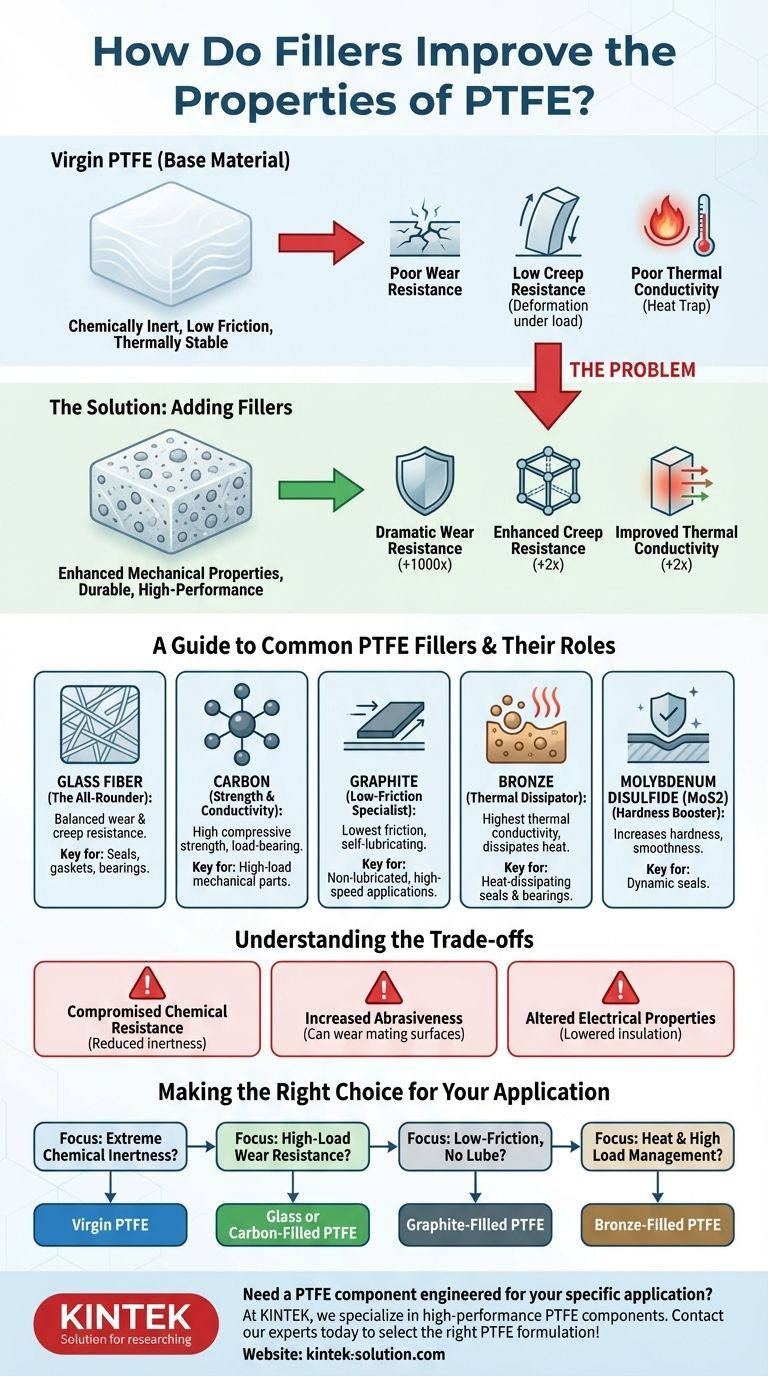

In short, fillers are added to Polytetrafluoroethylene (PTFE) to overcome its inherent mechanical weaknesses. While virgin PTFE offers remarkable chemical resistance and a low coefficient of friction, it suffers from poor resistance to wear and deformation under load. Adding fillers like glass, carbon, or bronze fundamentally enhances its mechanical properties, creating a tougher, more durable material for demanding applications.

The core purpose of adding fillers to PTFE is to transform it from a soft, compliant material into a high-performance engineering plastic. This is achieved by drastically improving its wear resistance, creep resistance (deformation under load), and thermal conductivity, making it suitable for mechanical components like seals, bearings, and gaskets.

The Foundation: Understanding Virgin PTFE's Limitations

To appreciate what fillers bring to PTFE, we must first understand the base material's unique profile of strengths and weaknesses.

Exceptional Chemical and Thermal Resistance

Virgin PTFE is renowned for its properties. It is almost universally chemically inert, meaning it resists corrosion and degradation from nearly all chemicals.

It also boasts an extremely low coefficient of friction, making it one of the most slippery materials known. Combined with its ability to withstand a wide range of temperatures (up to 260°C / 500°F), it's a premier choice for non-stick surfaces and low-friction environments.

The Core Weakness: Low Mechanical Strength

Despite its advantages, virgin PTFE is mechanically soft. Its primary limitations are poor abrasion resistance and low creep resistance.

This means it wears down quickly under friction and can slowly deform or "flow" out of shape when subjected to a constant load, especially at elevated temperatures.

Poor Thermal Conductivity

PTFE is an excellent thermal insulator. While this is an advantage in some applications, it can be a significant drawback in high-speed or high-load mechanical systems.

Friction generates heat, and without a way to dissipate it, the PTFE component can overheat, expand, and fail prematurely.

How Fillers Fundamentally Change PTFE

Fillers act as a reinforcing matrix within the PTFE, directly addressing its core mechanical and thermal deficiencies.

A Dramatic Boost in Wear Resistance

The single most significant improvement is in durability. Research shows that filled PTFE compounds can offer up to 1000 times greater abrasion resistance than virgin PTFE.

The filler particles bear the brunt of the frictional forces, protecting the softer PTFE matrix from being worn away.

Enhanced Creep Resistance

Fillers provide a rigid skeleton that helps the material resist deformation. A properly filled PTFE can have twice the creep resistance of its unfilled counterpart.

This makes it far more suitable for components like seals and gaskets that are under constant compressive force.

Improved Thermal Conductivity

Fillers like bronze or carbon create a pathway for heat to escape. Filled PTFE can have twice the thermal conductivity, allowing it to run cooler in dynamic applications.

This enhanced heat dissipation reduces thermal expansion and significantly increases the operational limits of bearings and seals.

A Guide to Common PTFE Fillers and Their Roles

The choice of filler depends entirely on the specific problem you need to solve. Each one imparts a different set of properties.

Glass Fiber: The All-Rounder

Glass fiber is one of the most common fillers. It provides an excellent balance of improved wear and creep resistance while maintaining good chemical and electrical properties.

Carbon: For Strength and Conductivity

Carbon enhances compressive strength and hardness, making PTFE more rigid and load-bearing. It also improves thermal conductivity and provides some electrical conductivity.

Graphite: The Low-Friction Specialist

While all PTFE is low-friction, adding graphite creates a self-lubricating compound. It is ideal for non-lubricated, high-speed applications where the lowest possible coefficient of friction is critical.

Bronze: The Thermal Dissipator

Bronze provides the highest thermal conductivity of all common fillers, making it the best choice for dissipating heat. It also offers excellent wear and creep resistance but has lower chemical resistance than other options.

Molybdenum Disulfide (MoS2): The Hardness Booster

Often used in combination with other fillers, MoS2 increases the hardness and smoothness of the material. It reduces the coefficient of friction and is excellent for dynamic seals.

Understanding the Trade-offs

Adding fillers is not a universal upgrade. You are always trading one property for another, and it's critical to understand these compromises.

Compromised Chemical Resistance

The primary trade-off is a reduction in chemical inertness. Fillers like bronze can be attacked by chemicals that would not affect virgin PTFE, limiting the applications where they can be used.

Increased Abrasiveness

Some fillers, particularly glass fiber, can be abrasive to softer mating surfaces like aluminum or other plastics. This must be considered in the overall system design.

Altered Electrical Properties

Virgin PTFE is an outstanding electrical insulator. Adding conductive fillers like carbon or bronze will dramatically lower its electrical resistance, making it unsuitable for applications requiring high dielectric strength.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation requires matching the material's properties to the demands of your environment.

- If your primary focus is extreme chemical inertness or FDA compliance: Virgin PTFE is the only suitable choice.

- If your primary focus is wear resistance in a high-load mechanical application: A glass or carbon-filled PTFE provides the necessary durability.

- If your primary focus is low friction in a non-lubricated, dynamic environment: Graphite-filled PTFE offers superior self-lubricating performance.

- If your primary focus is managing heat and high compressive loads: Bronze-filled PTFE provides the best thermal conductivity and strength.

By understanding the role of each filler, you can specify a PTFE compound perfectly engineered to your specific performance requirements.

Summary Table:

| Filler Type | Primary Benefits | Key Applications |

|---|---|---|

| Glass Fiber | Excellent wear & creep resistance, good chemical properties | Seals, gaskets, bearings |

| Carbon | High compressive strength, improved thermal & electrical conductivity | High-load mechanical parts |

| Graphite | Lowest coefficient of friction, self-lubricating | Non-lubricated, high-speed applications |

| Bronze | Highest thermal conductivity, excellent wear resistance | Heat-dissipating seals and bearings |

| Molybdenum Disulfide (MoS2) | Increased hardness, reduced friction | Dynamic seals |

Need a PTFE component engineered for your specific application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from custom seals and liners to specialized labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require virgin PTFE for unmatched chemical resistance or a filled compound for superior mechanical strength, our precision production and custom fabrication services ensure you get the exact solution, from prototypes to high-volume orders.

Let us help you select the right PTFE formulation to maximize performance and durability. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications