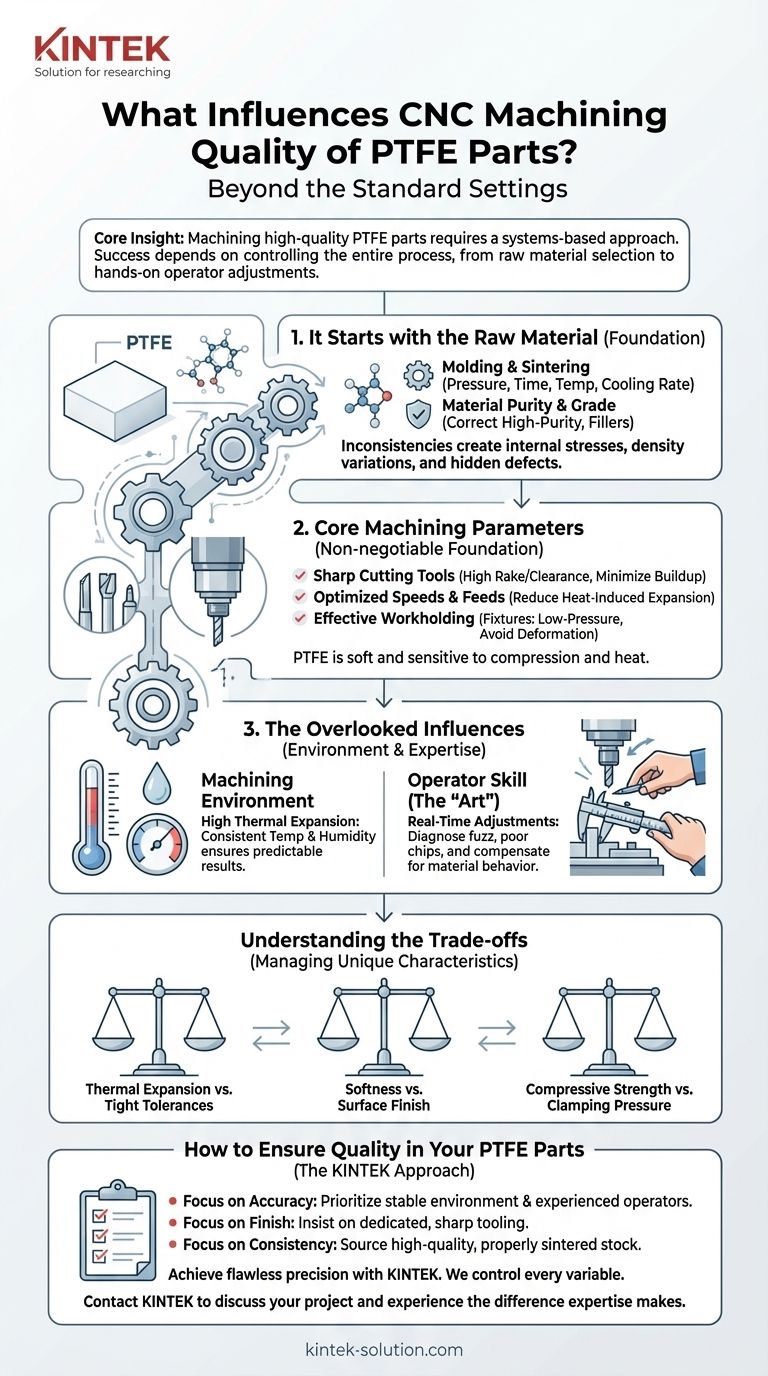

Beyond the standard machine settings, the final quality of a CNC machined PTFE part is profoundly influenced by the consistency of the raw material, the stability of the machining environment, and the expertise of the machine operator. These factors control variables like thermal expansion and material stress, which are critical when working with a soft, sensitive polymer like PTFE.

The core insight is that machining high-quality PTFE parts requires a systems-based approach. Success depends not just on programming the machine correctly, but on controlling the entire process from raw material selection to the hands-on adjustments made by a skilled operator.

It Starts with the Raw Material

Before a tool ever touches the workpiece, the quality of the raw PTFE stock sets the ultimate ceiling for the quality of the final part. PTFE is typically formed through compression molding and sintering, and variations in this initial process have downstream effects.

The Impact of Molding and Sintering

The properties of the PTFE block you start with are determined by its manufacturing process. Key variables include preforming pressure, sintering time and temperature, and the cooling rate.

Inconsistencies in these parameters can create internal stresses, density variations, or poor molecular fusion within the material. These hidden defects can later manifest as warping or dimensional instability during machining.

Material Purity and Grade

Different applications require different grades of PTFE, sometimes with fillers like glass, carbon, or bronze to enhance specific properties. Ensuring you are using the correct, high-purity grade for your application is a foundational step that prevents performance failures later.

Core Machining Parameters: The Foundation of Quality

While the user's question looks beyond these factors, it's crucial to acknowledge that they form the non-negotiable foundation for any quality part.

The Right Cutting Tools

PTFE is soft and abrasive, meaning tools must be exceptionally sharp to shear the material cleanly rather than pushing or tearing it. Tools with high rake and clearance angles are essential to prevent material buildup and ensure a smooth surface finish.

Optimized Speeds and Feeds

The goal is to cut the material without generating excessive heat. High spindle speeds combined with appropriate feed rates allow for efficient material removal while minimizing heat-induced expansion, which is a primary cause of dimensional inaccuracy in PTFE parts.

Effective Workholding (Fixtures)

Because PTFE is soft and easily compressed, the fixture design is critical. Fixtures must hold the part securely without deforming it. Over-tightening a clamp can compress the material, leading to an out-of-spec part once it's released and "relaxes."

The Overlooked Influences: Environment and Expertise

This is where many machining operations fail to achieve consistent quality with PTFE. The machine and the material do not exist in a vacuum.

The Machining Environment

PTFE has a very high coefficient of thermal expansion. Small changes in ambient temperature can cause the material to expand or contract enough to push it outside of tight tolerance bands.

Maintaining a consistent temperature and humidity in the machining environment reduces these variables, leading to more predictable and repeatable results.

The Role of Operator Skill

An experienced operator is arguably one of the most critical factors. They can visually inspect for signs of material "fuzz" or poor chip formation and make real-time adjustments to cutting parameters.

This hands-on expertise to diagnose and correct issues as they happen is something that cannot be fully programmed. It turns the art of machining into a reliable science, significantly improving both quality and efficiency.

Understanding the Trade-offs

Machining PTFE involves managing its unique, and sometimes challenging, characteristics. Acknowledging these trade-offs is key to successful part design and production.

Thermal Expansion vs. Tight Tolerances

The most significant trade-off is managing PTFE's high thermal expansion while trying to hold tight tolerances. This requires a climate-controlled environment, sharp tools to minimize cutting heat, and potentially letting the part normalize to room temperature before taking final measurements.

Softness vs. Surface Finish

PTFE’s softness makes it easy to cut but difficult to achieve a perfectly smooth, burr-free finish. It has a tendency to tear or create fine "hairs" rather than clean chips. This is counteracted with extremely sharp tooling and optimized toolpaths, but it remains a constant challenge.

Compressive Strength vs. Clamping Pressure

The material's low compressive strength means it can be easily crushed or deformed by workholding fixtures. The trade-off is between holding the part securely enough for aggressive machining versus using a light touch to prevent any deformation. This often requires custom, low-pressure fixture solutions.

How to Ensure Quality in Your PTFE Parts

To achieve consistent, high-quality results, you must consider the entire system of factors at play.

- If your primary focus is dimensional accuracy: Prioritize a stable, temperature-controlled machining environment and work with experienced operators who know how to compensate for thermal expansion.

- If your primary focus is surface finish: Insist on the use of exceptionally sharp, dedicated tooling designed specifically for soft polymers.

- If your primary focus is material consistency and performance: Begin by sourcing high-quality, properly sintered PTFE stock from a reputable supplier to eliminate material defects before machining even starts.

Ultimately, controlling every variable from the raw material to the final inspection is the only way to guarantee a truly high-quality machined PTFE component.

Summary Table:

| Factor | Key Influence on PTFE Machining Quality |

|---|---|

| Raw Material | Consistency from molding/sintering affects warping and dimensional stability. |

| Machining Environment | Temperature/humidity control minimizes PTFE's high thermal expansion. |

| Operator Skill | Real-time adjustments prevent fuzz, tearing, and ensure tight tolerances. |

| Cutting Tools | Sharp, high-rake tools are essential for a clean surface finish on soft PTFE. |

Achieve flawless precision for your PTFE components with KINTEK.

Machining sensitive polymers like PTFE requires a partner who controls every variable. KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We combine premium raw materials, climate-controlled facilities, and expert machinists to deliver custom parts that meet your tightest specifications—from prototypes to high-volume production.

Contact KINTEK today to discuss your project and experience the difference expertise makes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining