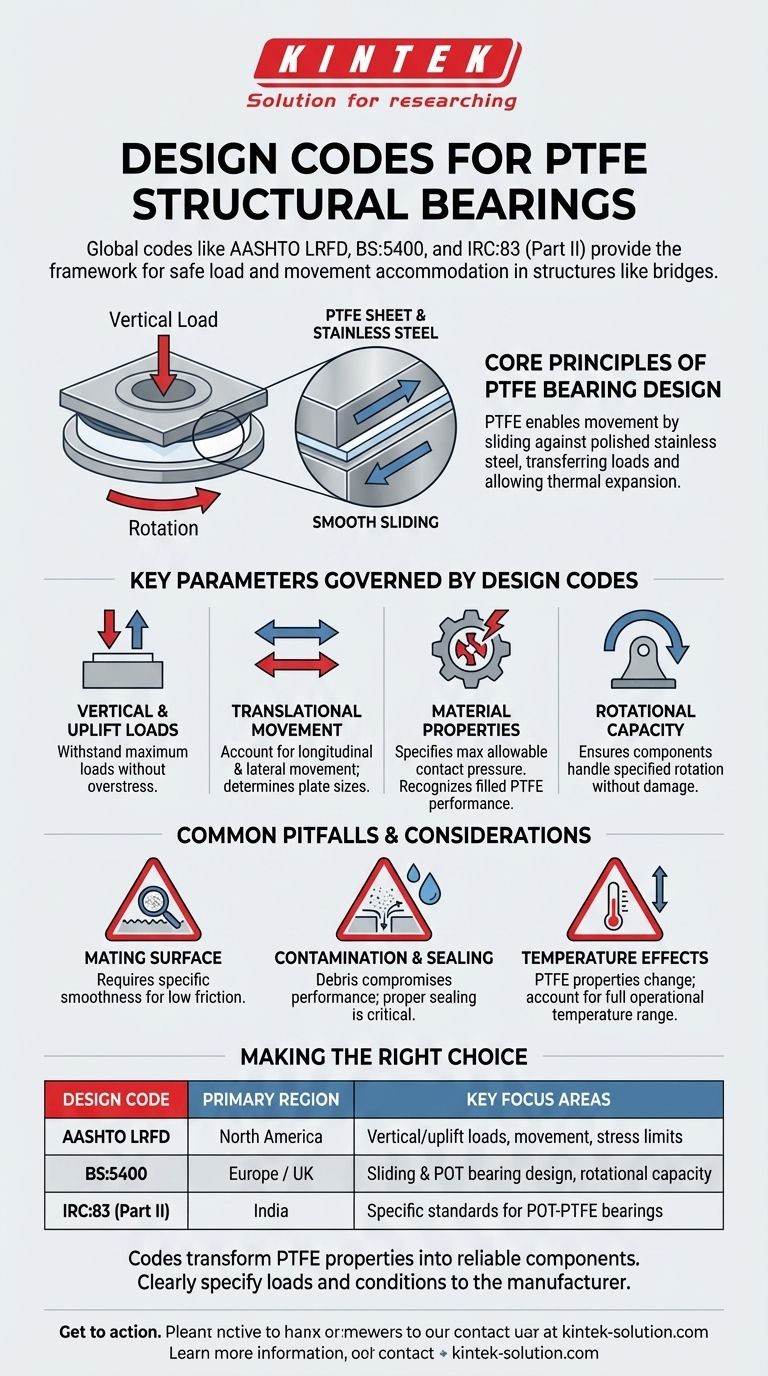

For PTFE structural bearings, the primary design codes used globally are AASHTO LRFD Bridge Design Specifications, the European standard BS:5400, and India's IRC:83 (Part II). These codes provide the essential framework for designing bearings that safely accommodate loads and movements in structures like bridges.

The specific design code you use is determined by project location and regulations, but all share a common goal: to provide a systematic method for designing a bearing that manages vertical loads, allows for specified movements, and accounts for the unique low-friction properties of PTFE.

The Core Principles of PTFE Bearing Design

A structural bearing's job is to transfer massive loads from one part of a structure to another while allowing for controlled movement. PTFE is essential to this process.

How PTFE Enables Movement

At its core, a sliding bearing consists of a PTFE sheet bonded to a backing plate. A highly polished stainless-steel plate rests on the PTFE.

This combination allows for smooth, near-frictionless sliding to accommodate thermal expansion, contraction, and other structural deformations.

Accommodating Loads and Rotation

Beyond simple sliding, these bearings are designed to handle immense vertical loads from the superstructure. They must also accommodate rotational movements, which occur when a beam deflects under load.

Key Parameters Governed by Design Codes

Design codes provide engineers with a standardized methodology for verifying that a bearing design is sufficient for the demands of a specific project. They focus on several critical parameters.

Vertical and Uplift Loads

The bearing must be designed to withstand the maximum calculated vertical load without being overstressed. Codes also provide guidance for handling potential uplift loads, which can occur from wind or seismic activity.

Translational Movement

The design must account for the total expected movement in both the longitudinal (along the length of the beam) and lateral (side-to-side) directions. The size of the PTFE and stainless-steel plates is directly calculated based on these movement requirements.

Material Properties and Stress Limits

Codes like AASHTO and BS:5400 specify the maximum allowable contact pressure (stress) on the PTFE material. They also recognize the superior performance of filled PTFE, which can handle significantly higher pressures and PV (Pressure-Velocity) values than pure PTFE.

Rotational Capacity

The bearing assembly, particularly in POT-PTFE types, must be designed to allow for a specified degree of rotation. The codes provide the formulas to ensure the components can handle this movement without binding or damage.

Common Pitfalls and Design Considerations

While the concept is straightforward, successful implementation requires careful attention to detail as outlined in the design standards.

The Critical Mating Surface

The extremely low coefficient of friction is only achieved when the PTFE slides against a compatible surface. Design codes specify the required smoothness (surface finish) of the stainless-steel plate, as any imperfection can increase friction and wear.

Contamination and Sealing

The effectiveness of a PTFE bearing can be severely compromised if dust, water, or debris gets between the sliding surfaces. Proper sealing and installation procedures are a critical part of the overall design to ensure long-term performance.

Temperature Effects

The properties of PTFE, including its dimensions and friction coefficient, can change with temperature. Engineering codes require the designer to account for the full operational temperature range at the project site.

Making the Right Choice for Your Project

The design of a PTFE bearing is a collaborative process between the structural engineer and the bearing manufacturer, guided by the governing code.

- If your project is in North America or follows U.S. standards: The AASHTO LRFD specifications will be your primary design guide.

- If your project adheres to British or European standards: BS:5400 provides the comprehensive framework for designing sliding and POT bearings.

- If your project is in India: IRC:83 (Part II) is the specific standard you must follow for POT-PTFE bearings.

- Regardless of the code: Your most critical task is to clearly specify all loads, movements, rotations, and site conditions to the manufacturer for a compliant design.

Ultimately, these codes transform the unique material properties of PTFE into a reliable and predictable structural component.

Summary Table:

| Design Code | Primary Region of Use | Key Focus Areas |

|---|---|---|

| AASHTO LRFD | North America | Vertical/uplift loads, movement, stress limits |

| BS:5400 | Europe / UK | Sliding & POT bearing design, rotational capacity |

| IRC:83 (Part II) | India | Specific standards for POT-PTFE bearings |

Need precision PTFE components for your structural bearing design?

KINTEK specializes in manufacturing high-performance, custom PTFE seals, liners, and components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production ensures your bearings meet the exacting requirements of AASHTO, BS:5400, and other global standards—from prototype to high-volume orders.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech