At its core, Polytetrafluoroethylene (PTFE) excels in anti-seize applications due to a unique combination of three fundamental properties: an exceptionally low coefficient of friction, high thermal stability, and remarkable chemical inertness. This trifecta ensures that threaded fasteners and metal components remain separate and adjustable, even under the most extreme operating conditions.

PTFE's effectiveness isn't just about simple lubrication; it's about creating a durable, non-reactive physical barrier between metal surfaces. This barrier remains stable across a wide range of temperatures and chemical environments, fundamentally preventing the metallurgical bonding and corrosion that cause seizing.

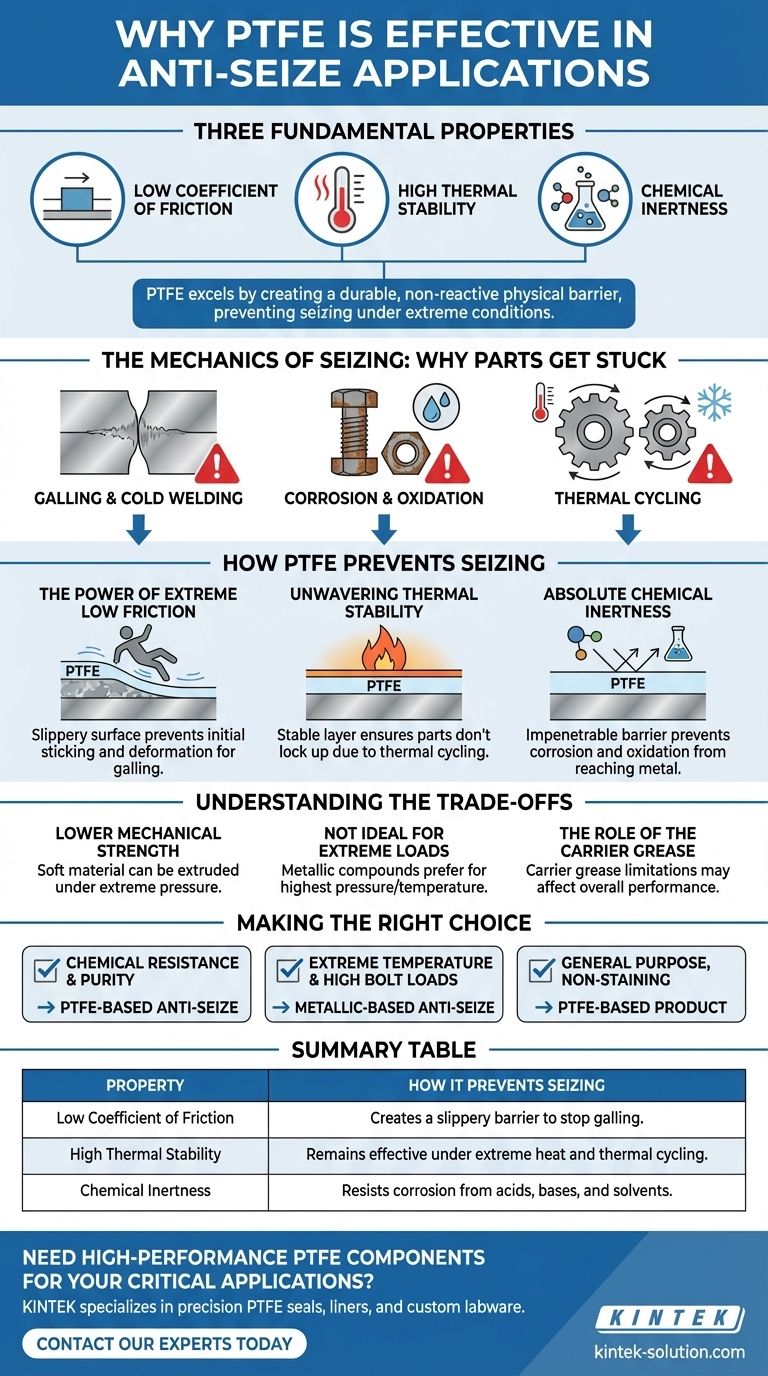

The Mechanics of Seizing: Why Parts Get Stuck

To understand why PTFE works, it's essential to first understand the problem it solves. Seizing is not a single issue but a combination of forces working to fuse components together.

Galling and Cold Welding

Under high pressure, such as when tightening a bolt, the microscopic peaks on two metal surfaces can deform and fuse. This phenomenon, known as galling or cold welding, creates a metallurgical bond that can make disassembly impossible without destroying the fastener.

Corrosion and Oxidation

When exposed to moisture and oxygen, metal surfaces can corrode or rust. This process creates a layer of oxide that can act like a cement, chemically locking threads and mating surfaces together.

Thermal Cycling

In high-temperature environments, components expand and contract. Different metals do this at different rates, which can create immense pressure and lock parts together over time.

How PTFE Prevents Seizing at a Molecular Level

PTFE systematically counteracts each of the primary causes of seizing by leveraging its unique molecular structure.

The Power of Extreme Low Friction

PTFE has one of the lowest coefficients of friction of any known solid. This creates an incredibly slippery surface between metal parts.

This physical slipperiness prevents the initial "sticking" and microscopic deformation required for galling and cold welding to occur, even under high clamping forces.

Unwavering Thermal Stability

PTFE exhibits high thermal stability, meaning it does not easily melt, burn, or degrade at the high temperatures found in engines, exhaust systems, and industrial machinery.

While other lubricants might burn off or carbonize into a solid, PTFE remains a stable, functional separating layer, ensuring parts don't lock up due to thermal cycling.

Absolute Chemical Inertness

PTFE is one of the most non-reactive substances known. It is virtually immune to degradation from acids, bases, solvents, oils, and other aggressive chemicals.

By acting as a perfect seal, it creates an impenetrable barrier that prevents corrosive agents from ever reaching the metal surfaces. This directly blocks the corrosion and oxidation processes that would otherwise fuse the parts.

Understanding the Trade-offs

While highly effective, PTFE-based anti-seize compounds are not a universal solution. Understanding their limitations is key to proper application.

Lower Mechanical Strength

PTFE is a soft material. In extremely high-pressure applications, it can be physically pushed, or "extruded," out from between the threads, reducing its effectiveness over time.

Not Ideal for Extreme Loads

For the highest-pressure and highest-temperature applications, metallic anti-seize compounds (containing copper, nickel, or aluminum) are often preferred. The metal particles provide a final physical barrier even if the grease carrier and PTFE are compromised.

The Role of the Carrier Grease

It's important to remember that PTFE is a solid additive within a grease base. The overall performance and temperature rating of the anti-seize product are often determined by the limitations of this carrier grease, which may break down at temperatures lower than the PTFE itself.

Making the Right Choice for Your Application

Selecting the right anti-seize compound depends entirely on the specific demands of your environment.

- If your primary focus is chemical resistance and purity: A PTFE-based anti-seize is an ideal choice, especially in food processing or electronics, where metallic contamination is unacceptable.

- If your primary focus is extreme temperature and high bolt loads: Consider a metallic-based anti-seize (like nickel or copper), as the metal particles provide a more robust physical barrier against galling.

- If you need a general-purpose, non-staining solution: A PTFE-based product offers excellent versatility for standard threaded fasteners where preventing corrosion and ensuring easy disassembly is the main goal.

Understanding these core principles allows you to select the precise compound that will protect your critical components and ensure their long-term serviceability.

Summary Table:

| Property | How It Prevents Seizing |

|---|---|

| Low Coefficient of Friction | Creates a slippery barrier to stop galling and cold welding. |

| High Thermal Stability | Remains effective under extreme heat and thermal cycling. |

| Chemical Inertness | Resists corrosion from acids, bases, and solvents. |

Need high-performance PTFE components for your critical applications?

KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware. Our components leverage the very properties discussed here—low friction, thermal stability, and chemical resistance—to solve complex challenges in the semiconductor, medical, laboratory, and industrial sectors.

Whether you require prototypes or high-volume production, we deliver solutions that ensure reliability and prevent failure. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability