In terms of performance, expanded PTFE (ePTFE) sheet is fundamentally superior to other PTFE-based gaskets for most demanding sealing applications. Its unique manufacturing process creates a soft, compressible material that excels in creating a tight, durable seal, especially on irregular or delicate surfaces, while overcoming the primary weaknesses of standard PTFE.

The core difference lies in structure: standard PTFE is a solid material prone to deformation (creep), while expanded PTFE is a porous, fibrous material that compresses to form a tight seal and strongly resists creep, ensuring long-term sealing integrity.

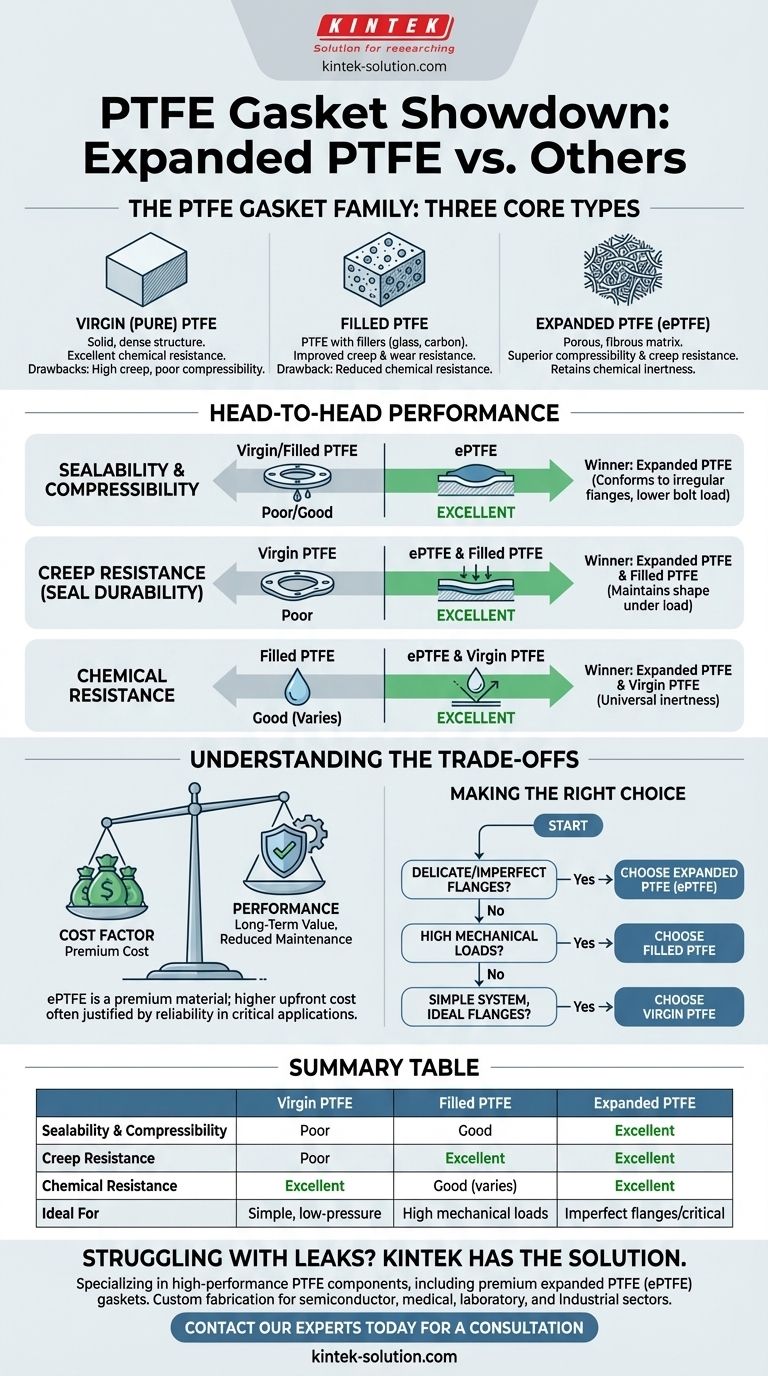

The PTFE Gasket Family: Three Core Types

To understand the comparison, it's essential to recognize the three primary forms of PTFE gasket material. Each originates from the same base polymer but is processed differently to achieve specific performance characteristics.

Virgin (or Pure) PTFE

This is the original, unadulterated form of PTFE. It is a solid, dense material known for its almost universal chemical resistance and exceptionally low coefficient of friction.

However, as a gasket, it suffers from two significant drawbacks: high creep (or "cold flow") and poor compressibility. It tends to deform and flow away from the flange load over time, leading to a loss of bolt torque and potential leaks.

Filled PTFE

To combat the weaknesses of virgin PTFE, manufacturers add filler materials like glass, silica, or carbon. This process creates "filled PTFE."

These fillers dramatically improve the gasket's resistance to creep and wear. The trade-off is that the filler material can slightly reduce the overall chemical resistance of the gasket, as it may not be as inert as the PTFE itself.

Expanded PTFE (ePTFE)

Expanded PTFE is created through a special process that stretches the PTFE, transforming its dense structure into a porous, fibrous, and multi-directional matrix.

This soft, malleable structure is the key to its superior performance. It retains the exceptional chemical and thermal resistance of virgin PTFE but adds outstanding compressibility and excellent creep resistance.

Head-to-Head Performance Comparison

When selecting a gasket, three properties are paramount: the ability to create an initial seal, the ability to maintain that seal over time, and chemical compatibility.

Winner in Sealability and Compressibility: Expanded PTFE

Expanded PTFE is the undisputed leader here. Its soft, porous structure allows it to conform easily to surface imperfections, scratches, or waviness in a flange.

This means ePTFE can create a highly reliable seal with much lower bolt-clamping force compared to solid gaskets. This makes it ideal for delicate or non-metallic flanges (e.g., glass-lined steel, plastic). Virgin PTFE is particularly poor in this regard.

Winner in Creep Resistance (Seal Durability): Expanded PTFE & Filled PTFE

Creep is the tendency of a material to deform under a constant load, and it is the primary cause of gasket failure in standard PTFE.

Filled PTFE was specifically designed to solve this problem and offers excellent creep resistance. However, the fibrous, interlocking structure of expanded PTFE also gives it exceptional resistance to creep, ensuring it maintains its shape and the integrity of the seal over long periods and through thermal cycles.

Winner in Chemical Resistance: Virgin PTFE & Expanded PTFE

Virgin PTFE is the benchmark for chemical inertness, resistant to nearly all industrial chemicals.

Expanded PTFE is made from pure PTFE and therefore retains this same outstanding chemical resistance across the full pH range. Filled PTFE gaskets are generally excellent but can be vulnerable if the specific chemical in service attacks the filler material.

Understanding the Trade-offs

No single material is perfect for every scenario. While ePTFE offers superior performance, there are practical considerations to keep in mind.

The Cost Factor

The advanced manufacturing process for ePTFE makes it a premium material. It is generally more expensive than virgin or most standard filled PTFE grades.

This higher upfront cost is often justified by reduced maintenance, longer service life, and the prevention of costly leaks, especially in critical or hazardous service.

When Simpler Is Better

For non-critical applications with perfect, rigid steel flanges and stable operating conditions, the high performance of ePTFE may be unnecessary.

In these situations, a less expensive filled or virgin PTFE gasket may provide perfectly adequate performance, making it a more cost-effective choice.

Making the Right Choice for Your Application

Your final decision should be driven by the specific demands of your equipment and process fluid.

- If your primary focus is maximum sealability on imperfect, damaged, or delicate flanges: Choose expanded PTFE (ePTFE) for its unmatched compressibility and ability to seal with low bolt load.

- If your primary focus is resisting high mechanical loads and creep in a standard application: A specific grade of filled PTFE is likely your most cost-effective, high-performance option.

- If your primary focus is universal chemical inertness in a simple, low-pressure system with ideal flanges: Virgin PTFE is a suitable and economical choice.

Ultimately, selecting the right gasket is about matching the material's mechanical properties to the unique demands of your sealing challenge.

Summary Table:

| Property | Virgin PTFE | Filled PTFE | Expanded PTFE (ePTFE) |

|---|---|---|---|

| Sealability & Compressibility | Poor | Good | Excellent |

| Creep Resistance | Poor | Excellent | Excellent |

| Chemical Resistance | Excellent | Good (varies by filler) | Excellent |

| Ideal For | Simple, low-pressure systems | High mechanical loads | Imperfect/delicate flanges, critical seals |

Struggling with flange leaks or unreliable seals? KINTEK specializes in manufacturing high-performance PTFE components, including premium expanded PTFE (ePTFE) gaskets, seals, and liners. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the perfect sealing solution for your specific application in the semiconductor, medical, laboratory, and industrial sectors.

Let us help you enhance your sealing integrity and operational efficiency. Contact our experts today for a consultation to discuss your requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts