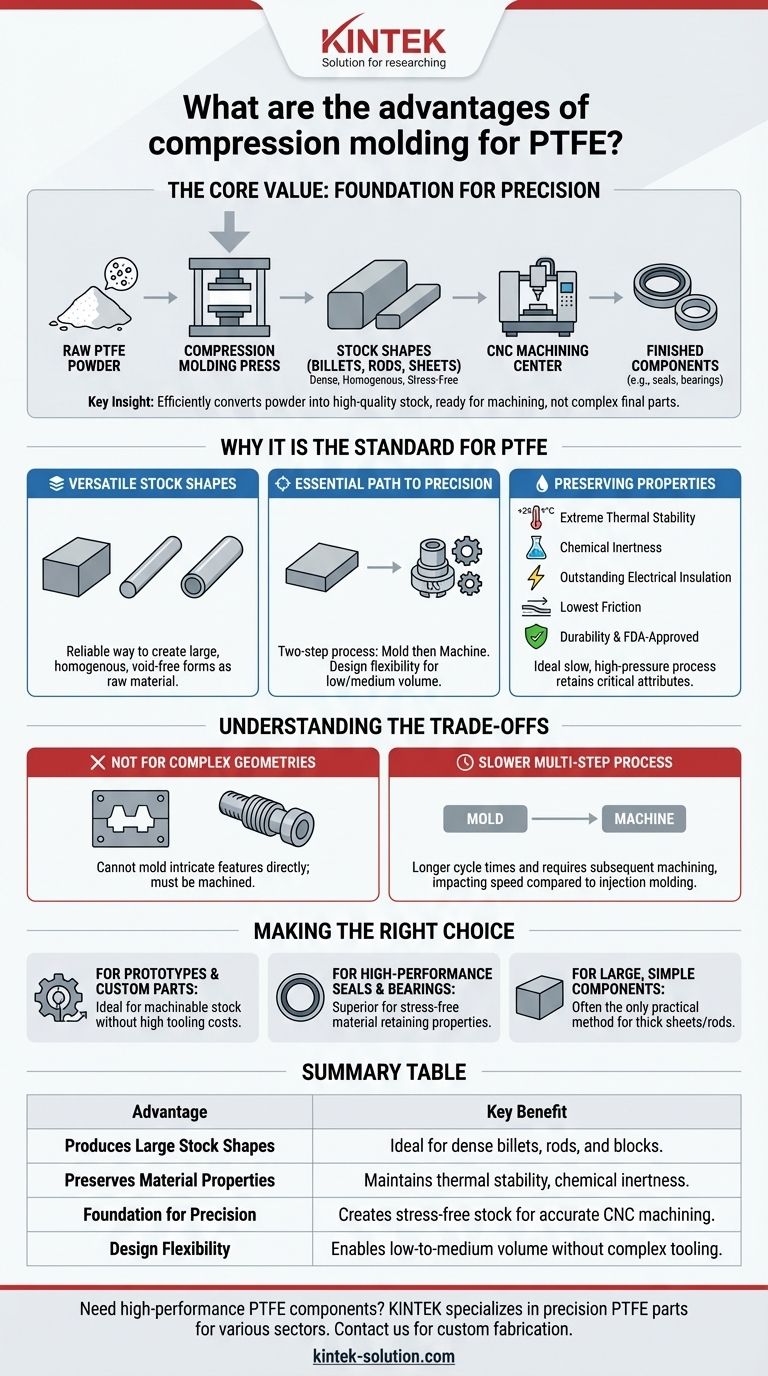

The primary advantage of compression molding for PTFE is its unmatched capability for producing large, dense, and simple stock shapes like rods, sheets, and blocks. This method is the foundational step for creating high-quality, stress-free billets from raw PTFE powder, which can then be precision machined into finished components.

The core value of compression molding for PTFE isn't in creating a finished, complex part directly. Its true advantage lies in efficiently converting raw PTFE powder into a solid, high-quality billet that fully preserves the material's exceptional properties, making it ready for precision machining.

Why Compression Molding is the Standard for PTFE

Polytetrafluoroethylene (PTFE) has a unique combination of properties that make it difficult to process with common melt-based methods like injection molding. Compression molding is perfectly suited to the material's nature.

Creating Versatile Stock Shapes

The most common output of PTFE compression molding is not a final part, but a stock shape. These large, solid forms—such as billets, tubes, and sheets—serve as the raw material for a subsequent manufacturing step.

This is the most reliable way to create a large, homogenous, and void-free piece of PTFE.

The Essential Path to Precision

Because compression molding produces simple shapes, CNC machining is almost always the next step. The molded stock is machined to create the final part with tight tolerances and specific features.

This two-step process—mold then machine—provides immense design flexibility for low-to-medium volume production without the need for expensive and complex tooling.

Preserving PTFE's Unmatched Properties

PTFE is valued for its extraordinary characteristics, and compression molding is the ideal process to preserve them. The slow, high-pressure process ensures the finished billet retains these key attributes.

These properties include:

- Extreme Thermal Stability: PTFE offers a continuous working temperature of up to +260°C, the highest of any fluoroplastic.

- Near-Universal Chemical Inertness: It is resistant to nearly all chemicals, acids, and bases.

- Outstanding Electrical Insulation: It has a very high dielectric strength, making it a top-tier electrical insulator.

- Lowest Coefficient of Friction: Its surface is famously non-stick and low-friction, critical for bearings and seals.

- Durability and Purity: The material is weatherable, hydrophobic, and often FDA-approved for food-grade applications.

Understanding the Trade-offs

While it is the standard for PTFE, compression molding has clear limitations that are important to understand. It is a specific tool for a specific job.

Not Suited for Complex Geometries

This process is not designed to create intricate parts directly from the mold. Features like threads, sharp internal corners, or complex surface details cannot be molded in.

Such features must be added later through machining. This stands in contrast to injection molding, which can produce highly complex parts in a single step for other types of plastics.

A Two-Step Manufacturing Process

The reliance on subsequent machining means that creating a finished PTFE part is inherently a multi-step process. This can impact production time and cost compared to single-shot manufacturing methods.

Slower Cycle Times

Compression molding is a deliberate and relatively slow process. It is not suited for the kind of high-volume, rapid-cycle production associated with other molding techniques.

Making the Right Choice for Your Application

Selecting the right process depends entirely on your material and final goal. For PTFE, the choice is clear when your priorities align with the process's strengths.

- If your primary focus is prototypes or custom parts: Compression molding is ideal because it creates machinable stock without the high upfront cost of complex tooling.

- If your primary focus is high-performance seals, insulators, or bearings: This method is superior because it produces stress-free material that fully retains PTFE's critical thermal, chemical, and electrical properties.

- If your primary focus is large, simple components: For producing a thick sheet, a large-diameter rod, or a block of PTFE, compression molding is often the only practical and reliable manufacturing method.

Ultimately, choosing compression molding is about leveraging a straightforward process to unlock the full, uncompromising performance of PTFE.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Produces Large Stock Shapes | Ideal for creating dense rods, sheets, and blocks (billets). |

| Preserves Material Properties | Maintains PTFE's extreme thermal stability, chemical inertness, and low friction. |

| Foundation for Precision | Creates stress-free billets ready for accurate CNC machining. |

| Design Flexibility | Enables low-to-medium volume production without complex tooling. |

Need high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in compression molding ensures your parts deliver unmatched chemical resistance, thermal stability, and durability.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the material properties you depend on.

Contact KINTEK today to discuss your PTFE project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability