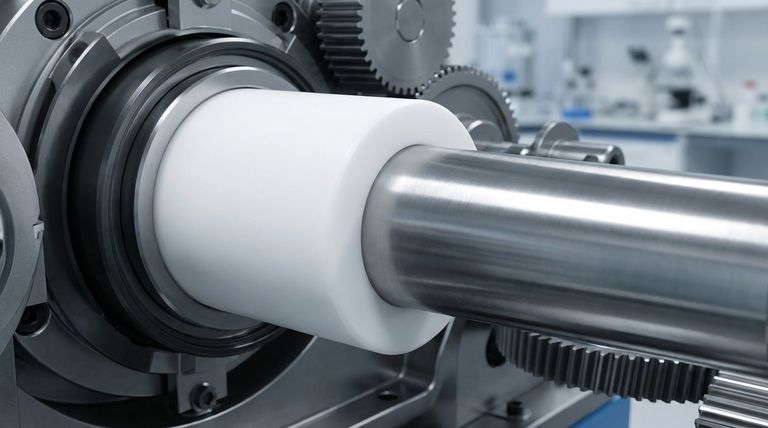

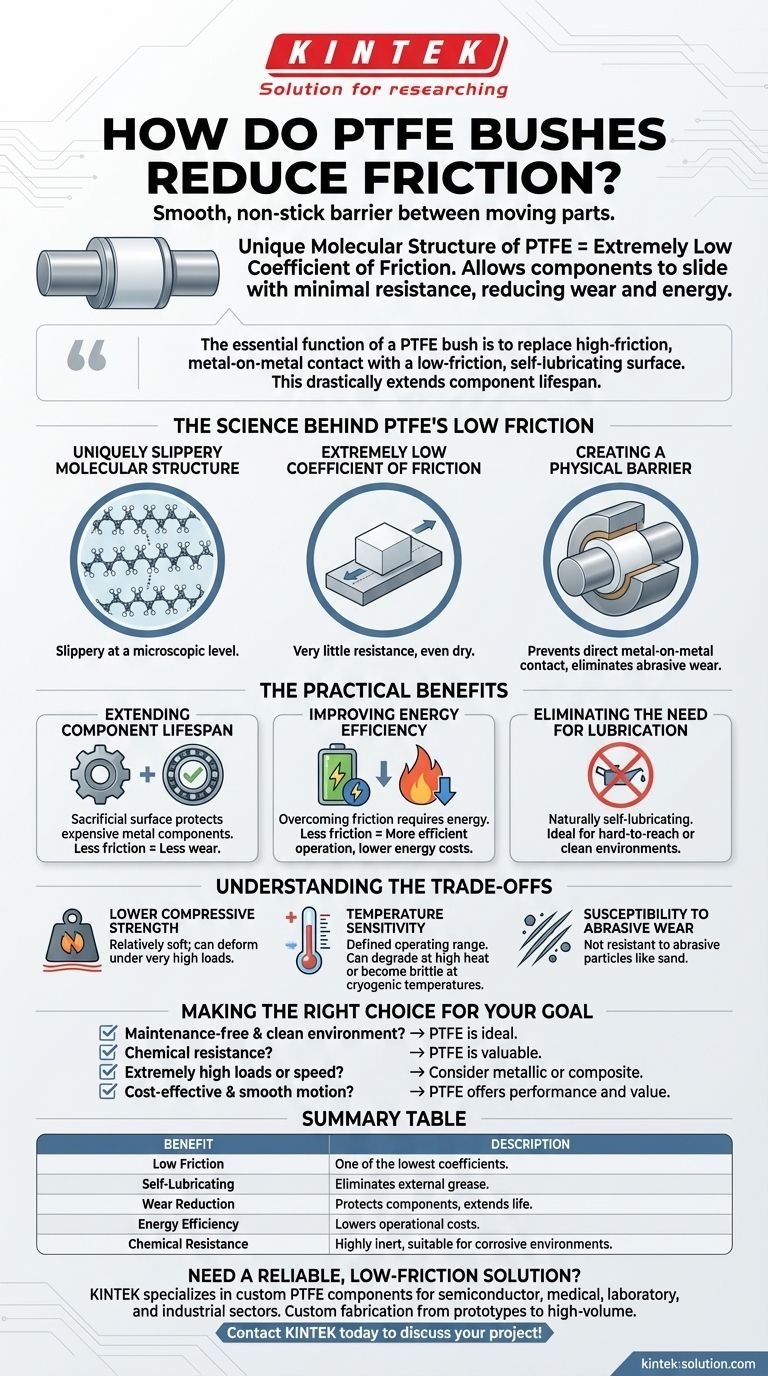

At its core, a PTFE bush reduces friction by acting as an extremely smooth, non-stick barrier between two moving parts. Its effectiveness comes from the unique molecular structure of Polytetrafluoroethylene (PTFE), which gives it one of the lowest coefficients of friction of any solid material. This allows components to slide against each other with minimal resistance, significantly reducing both wear and the energy required for movement.

The essential function of a PTFE bush is to replace high-friction, metal-on-metal contact with a low-friction, self-lubricating surface. This not only makes movement easier but also drastically extends the lifespan of the components involved.

The Science Behind PTFE's Low Friction

To understand why PTFE is so effective, we need to look beyond its role as a simple barrier and examine its fundamental properties. Its performance is rooted in its chemistry and physical characteristics.

A Uniquely "Slippery" Molecular Structure

The material known as PTFE has a unique molecular structure that results in very weak forces between its molecules. This inherent property is what gives it the famous non-stick quality seen in cookware and is the primary reason it is so "slippery" at a microscopic level.

An Extremely Low Coefficient of Friction

Coefficient of friction is a measure of how much force is required to move two surfaces against each other. PTFE has an exceptionally low coefficient, meaning parts slide past it with very little resistance. This property holds true even in dry, non-lubricated conditions where traditional metal bearings would fail.

Creating a Physical Barrier

The most straightforward function of the bush is to physically separate two components, typically metal shafts and housings. By preventing direct metal-on-metal contact, the bush immediately eliminates a primary source of abrasive wear, galling, and heat generation.

The Practical Benefits of Reduced Friction

Lowering friction isn't just a technical goal; it produces tangible improvements in a machine's performance, longevity, and efficiency.

Extending Component Lifespan

By acting as a sacrificial, low-wear surface, a PTFE bush protects more critical and expensive metal components from damage. Less friction directly translates to less wear and tear, which significantly extends the operational life of the entire assembly.

Improving Energy Efficiency

Overcoming friction requires energy. In any mechanical system, from a simple hinge to a complex industrial valve, reducing friction means less energy is wasted as heat. This results in more efficient operation and lower energy costs over time.

Eliminating the Need for Lubrication

Many traditional bearing systems require regular application of grease or oil to function correctly. Because PTFE is naturally self-lubricating, it is an ideal choice for applications where maintenance is difficult or where lubricants could contaminate the product.

Understanding the Trade-offs

While PTFE is an exceptional material, it is not the solution for every application. Understanding its limitations is critical for proper engineering design.

Lower Compressive Strength

Compared to metal bearings (like bronze or steel), PTFE is a relatively soft material. Under very high loads, it can deform or "creep" over time, which may not be suitable for high-stress structural applications.

Temperature Sensitivity

PTFE has a defined operating temperature range. At excessively high temperatures, it can degrade, while at cryogenic temperatures, it can become brittle. Metal bearings often have a much wider operating temperature window.

Susceptibility to Abrasive Wear

While PTFE excels at reducing sliding friction, it is not as resistant to abrasive particles (like sand or grit) as hardened metals. In dirty or abrasive environments, a different material or a sealed bearing design may be necessary.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the demands of your specific application.

- If your primary focus is maintenance-free operation in a clean environment: PTFE is an ideal choice due to its self-lubricating properties.

- If your primary focus is chemical resistance: PTFE's inertness makes it invaluable for machinery handling corrosive liquids or gases.

- If your primary focus is handling extremely high loads or high-speed rotation: A metallic or composite bearing may be a more durable solution.

- If your primary focus is cost-effective, smooth motion for light-to-medium loads: PTFE bushes offer an excellent balance of performance and value.

By understanding its fundamental properties and limitations, you can leverage PTFE to create more efficient, reliable, and durable mechanical systems.

Summary Table:

| Benefit | Description |

|---|---|

| Low Friction | PTFE has one of the lowest coefficients of friction of any solid material. |

| Self-Lubricating | Eliminates the need for external grease or oil, ideal for maintenance-free operation. |

| Wear Reduction | Acts as a sacrificial barrier, protecting expensive metal components and extending lifespan. |

| Energy Efficiency | Less friction means less energy is wasted as heat, lowering operational costs. |

| Chemical Resistance | Highly inert, making it suitable for corrosive environments in semiconductor, medical, and lab settings. |

Need a reliable, low-friction solution for your application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom bushes, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you achieve maintenance-free operation, extend component life, and improve energy efficiency.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs.

Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is high temperature stability important for Teflon gland fillers? Ensuring Leak-Free Seals in Harsh Chemical Processes

- What are the key steps in the manufacturing process of PTFE coated fasteners? Build a Durable, Corrosion-Resistant Shield

- What are the key benefits of PTFE (Teflon) gaskets? Superior Chemical & Temperature Resistance

- What environmental factors do PTFE bellows resist? Superior Chemical and Thermal Resilience for Demanding Applications

- What are the key properties of PTFE balls? Unlock Superior Performance for Demanding Applications

- What additional safety feature do PTFE compensators provide? Prevent Electrical Sparks in Hazardous Environments

- Why are PTFE expansion bellows considered versatile in technology? Mastering Chemical, Thermal, and Mechanical Challenges

- Why does the spring PTFE sealing ring maintain effective sealing across its working pressure range? Discover the Engineering Secret