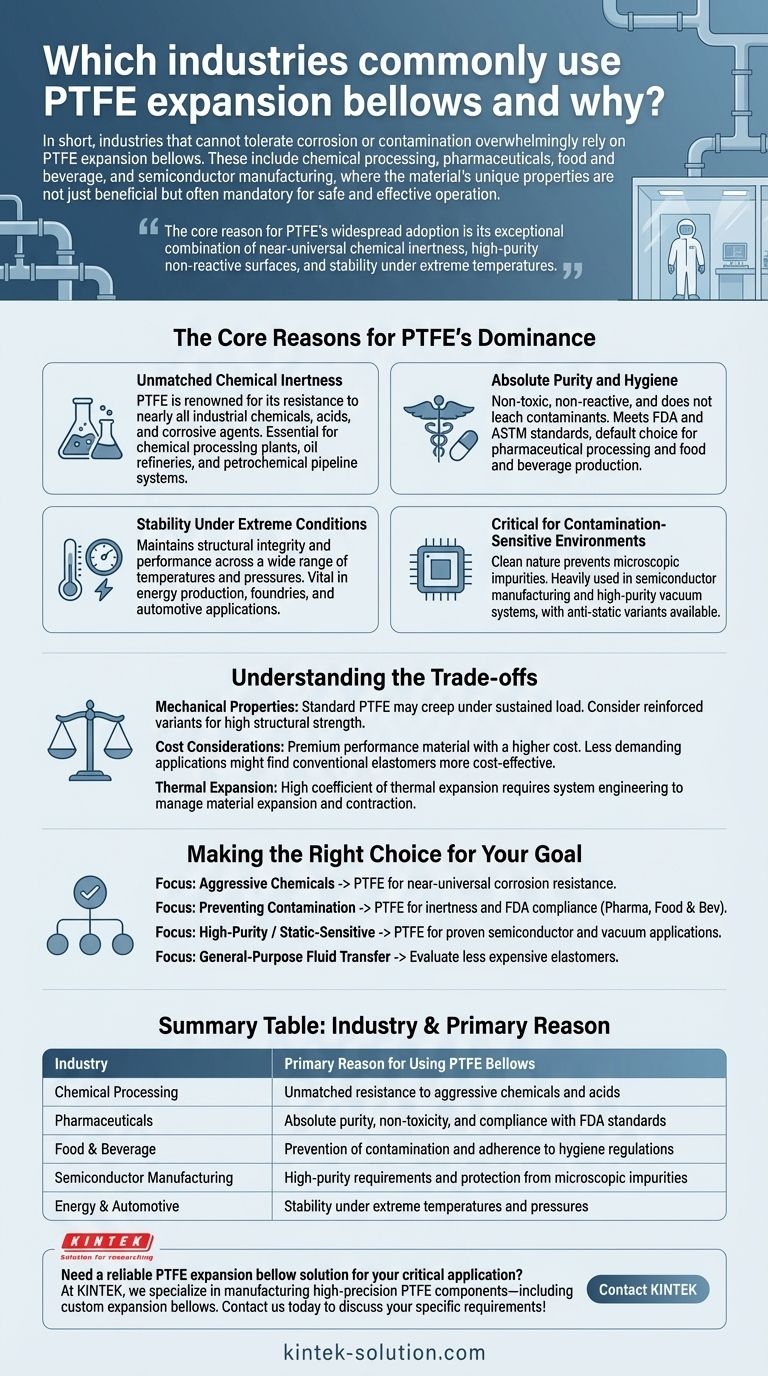

In short, industries that cannot tolerate corrosion or contamination overwhelmingly rely on PTFE expansion bellows. These include chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing, where the material's unique properties are not just beneficial but often mandatory for safe and effective operation.

The core reason for PTFE's widespread adoption is its exceptional combination of near-universal chemical inertness, high-purity non-reactive surfaces, and stability under extreme temperatures. This makes it an essential problem-solver in the most demanding industrial environments.

The Core Reasons for PTFE's Dominance

To understand why PTFE expansion bellows are so critical, we must look beyond a simple list of industries and analyze the fundamental problems they solve. The material's inherent properties directly address the biggest challenges in several high-stakes sectors.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, acids, and corrosive agents. This property makes it indispensable in environments where other materials would quickly degrade.

This is the primary reason it's a first-choice material in chemical processing plants, oil refineries, and petrochemical pipeline systems that handle aggressive media.

Absolute Purity and Hygiene

The material is non-toxic, non-reactive, and does not leach contaminants into the substances it contacts. This is a non-negotiable requirement in highly regulated fields.

Because PTFE can meet stringent FDA and ASTM standards, it is the default choice for pharmaceutical processing and food and beverage production, where preventing cross-contamination is critical for product safety and compliance.

Stability Under Extreme Conditions

PTFE bellows maintain their structural integrity and performance across a wide range of temperatures and pressures. They reliably absorb shock and vibration in demanding piping networks.

This thermal and mechanical resilience makes them vital in energy production, foundries, and automotive applications where harsh operating conditions are the norm.

Critical for Contamination-Sensitive Environments

In industries where even microscopic impurities can ruin a product, the clean nature of PTFE is paramount.

This is why it's heavily used in semiconductor manufacturing and high-purity vacuum systems. For applications where static electricity is a risk, specialized anti-static PTFE variants are available to safely dissipate any charge.

Understanding the Trade-offs

While its properties are exceptional, choosing PTFE is not without considerations. As an advisor, it's my responsibility to provide a complete picture.

Mechanical Properties

Standard PTFE is not the most rigid material and can be susceptible to creep under sustained load. In applications with high abrasion or where significant structural strength is required, other materials or reinforced PTFE variants may be more suitable.

Cost Considerations

PTFE is a premium performance material, and its cost generally reflects that. For less demanding applications, such as a simple HVAC system with non-corrosive media, a more conventional elastomer like EPDM might be a more cost-effective solution.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. While the bellows are designed to manage this, the entire system must be engineered to account for the material's tendency to expand and contract with temperature changes.

Making the Right Choice for Your Goal

Your specific application dictates whether PTFE is the correct choice. Use these points as a guide.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal corrosion resistance makes it the safest and most reliable option.

- If your primary focus is preventing product contamination: PTFE's inertness and compliance with FDA standards are essential for the pharmaceutical and food industries.

- If your primary focus is high-purity or static-sensitive manufacturing: PTFE is a proven material for semiconductor and vacuum applications, with anti-static versions available.

- If your primary focus is general-purpose fluid transfer in a mild environment: You should evaluate whether a more common and less expensive elastomer could meet your needs.

Ultimately, PTFE expansion bellows are the definitive engineering choice for any system where material purity and resilience cannot be compromised.

Summary Table:

| Industry | Primary Reason for Using PTFE Bellows |

|---|---|

| Chemical Processing | Unmatched resistance to aggressive chemicals and acids |

| Pharmaceuticals | Absolute purity, non-toxicity, and compliance with FDA standards |

| Food & Beverage | Prevention of contamination and adherence to hygiene regulations |

| Semiconductor Manufacturing | High-purity requirements and protection from microscopic impurities |

| Energy & Automotive | Stability under extreme temperatures and pressures |

Need a reliable PTFE expansion bellow solution for your critical application? At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom expansion bellows—for semiconductor, medical, laboratory, and industrial applications. Our expertise ensures your systems operate with uncompromised purity and chemical resistance. Contact us today to discuss your specific requirements from prototype to high-volume production!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does Reinforced PTFE differ from Virgin PTFE? Unlock the Right Material for Your Application

- What factors should be considered when selecting between PTFE and EPDM valve seats for butterfly valves? Ensure Long-Term Reliability and Avoid Costly Failures

- What are the performance specifications of PTFE-lined bearings? Achieve Maintenance-Free, High-Load Performance

- What are the three main factors to consider when selecting ball valve seat materials? Ensure System Reliability

- What are the key properties of PTFE valves? Ensure Purity, Safety, and Reliability in Demanding Processes

- In what applications are PTFE liners commonly used? Critical Solutions for Harsh Environments

- How do different glass weave styles affect phase response in RF PCBs? Ensure Phase Coherence for High-Frequency Designs

- What are the key features of PTFE bellows? Protect Critical Systems from Chemical & Thermal Stress