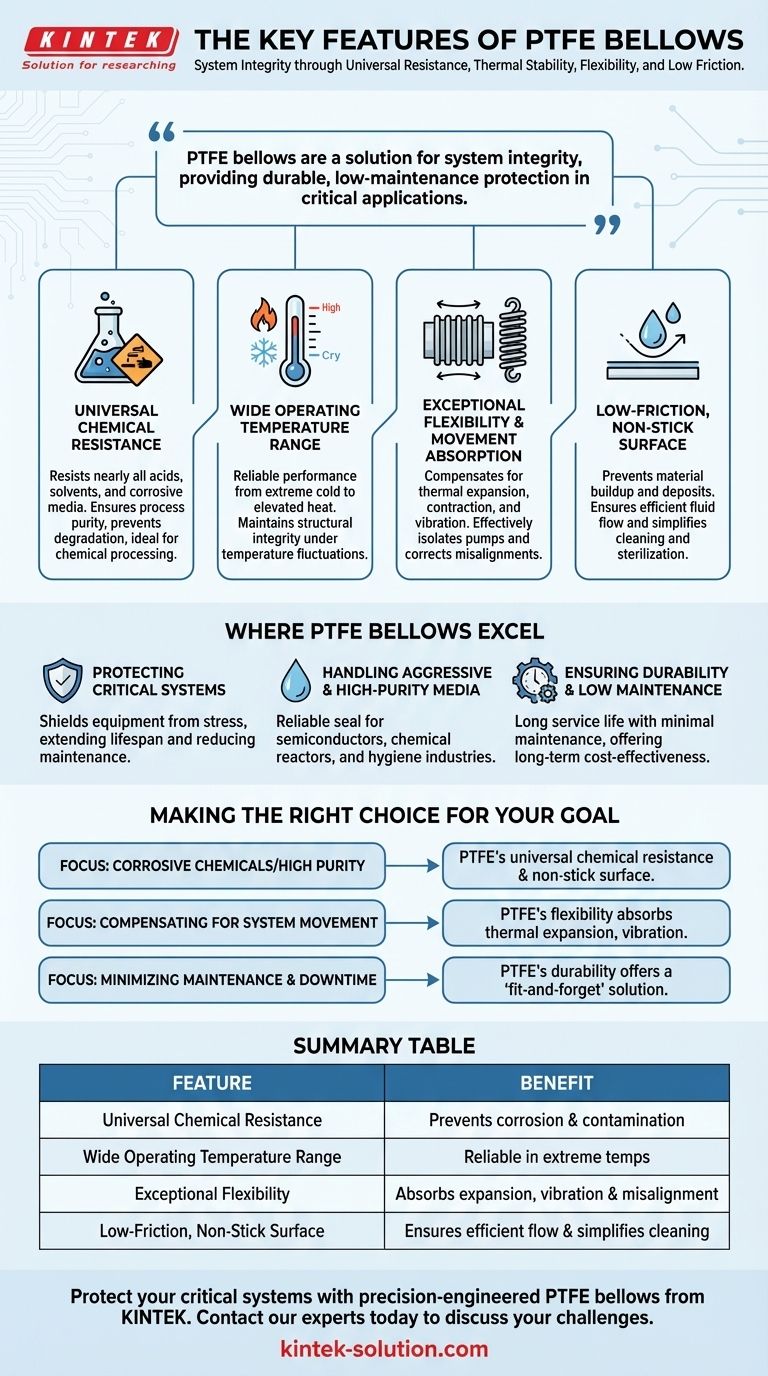

At their core, PTFE bellows are defined by four key features: exceptional chemical resistance, high flexibility, a wide operating temperature range, and a low-friction, non-stick surface. These properties allow them to protect critical systems by handling aggressive chemicals and absorbing movement from thermal expansion or vibration in demanding industrial environments.

PTFE bellows are not just components; they are a solution for system integrity. Their primary value is providing durable, low-maintenance protection in applications where chemical corrosion, extreme temperatures, or mechanical stress would cause other materials to fail.

The Core Properties of PTFE Bellows

To understand why PTFE bellows are specified for such critical tasks, it's essential to break down their fundamental characteristics. Each feature directly addresses a common engineering challenge.

Universal Chemical Resistance

PTFE is one of the most chemically inert materials known. This gives the bellows universal resistance to nearly all industrial chemicals, acids, and corrosive media.

This inertness ensures the bellows will not degrade, contaminate the process fluid, or fail when exposed to aggressive substances, making them a first-choice material for chemical processing and petrochemical pipelines.

Wide Operating Temperature Range

PTFE exhibits remarkable thermal stability. It maintains its structural integrity and performance characteristics across a broad spectrum of temperatures, from cryogenic conditions to elevated heat.

This allows PTFE bellows to function reliably in systems that experience significant temperature fluctuations without becoming brittle or weak.

Exceptional Flexibility and Movement Absorption

Bellows are designed to move. PTFE's inherent flexibility allows them to effectively compress, extend, and deflect to compensate for system stressors.

They are ideal for absorbing thermal expansion and contraction in pipework, isolating vibration from pumps or motors, and correcting minor misalignments between system parts.

Low-Friction, Non-Stick Surface

The surface of PTFE is inherently non-adhesive and low-friction. Materials, whether fluid or solid, do not easily stick to it.

This "non-stick" property prevents the buildup of deposits within the bellows' convolutions, ensuring efficient fluid flow, reducing the risk of blockages, and simplifying cleaning and sterilization processes.

Where PTFE Bellows Excel

The unique combination of these properties makes PTFE bellows a superior choice for specific high-stakes applications where reliability and purity are non-negotiable.

Protecting Critical Systems

The primary function of a bellow is often to act as a balancing and protective element. They are installed between engineering parts to shield equipment from mechanical, chemical, and thermal stress.

By absorbing these forces, they extend the lifespan of more expensive or sensitive equipment and reduce the need for maintenance.

Handling Aggressive and High-Purity Media

From semiconductor manufacturing plants to chemical reactors, PTFE bellows provide a reliable seal and flexible connection that can withstand the harshest environments.

Their purity and FDA compliance also make them suitable for industries requiring high hygiene standards, such as food production and medical appliances, where they can be effectively sterilized.

Ensuring Durability and Low Maintenance

The chemical and environmental stability of PTFE directly translates to a long service life. Once installed, these bellows require minimal to no maintenance.

This durability reduces operational costs and downtime, making them a cost-effective solution over the long term despite a potentially higher initial investment compared to other materials.

Making the Right Choice for Your Goal

Selecting PTFE bellows is a strategic decision based on the specific demands of your system.

- If your primary focus is handling corrosive chemicals or high-purity media: The universal chemical resistance and non-stick surface of PTFE make it the safest and most reliable choice.

- If your primary focus is compensating for system movement: PTFE's flexibility is essential for absorbing thermal expansion, vibration, and misalignment, preventing stress on pipes and equipment.

- If your primary focus is minimizing long-term maintenance and downtime: The exceptional durability and longevity of PTFE offer a "fit-and-forget" solution for critical connection points.

Ultimately, choosing PTFE bellows is an investment in the long-term stability and reliability of your entire system.

Summary Table:

| Key Feature | Primary Benefit |

|---|---|

| Universal Chemical Resistance | Withstands aggressive acids and solvents, preventing corrosion and contamination. |

| Wide Operating Temperature Range | Performs reliably from cryogenic to high-heat environments without degrading. |

| Exceptional Flexibility | Absorbs movement from thermal expansion, vibration, and misalignment. |

| Low-Friction, Non-Stick Surface | Prevents material buildup, ensures efficient flow, and simplifies cleaning/sterilization. |

Protect your critical systems with precision-engineered PTFE bellows from KINTEK.

Our PTFE components are manufactured to the highest standards of precision and durability, serving the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard part or a custom-fabricated solution from prototype to high-volume production, KINTEK delivers the reliability your application demands.

Contact our experts today to discuss how our PTFE bellows can solve your specific chemical, thermal, or mechanical challenges and ensure long-term system integrity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems