At their core, PTFE valves are specified for industrial processes due to three defining characteristics: near-universal chemical inertness, high-temperature stability, and an exceptionally low coefficient of friction. These properties ensure they can handle aggressive or high-purity substances without degrading, contaminating the media, or failing under harsh conditions.

The decision to use a PTFE valve is fundamentally about ensuring process integrity. Its unique combination of material properties delivers reliability, safety, and purity in applications where conventional materials would quickly fail.

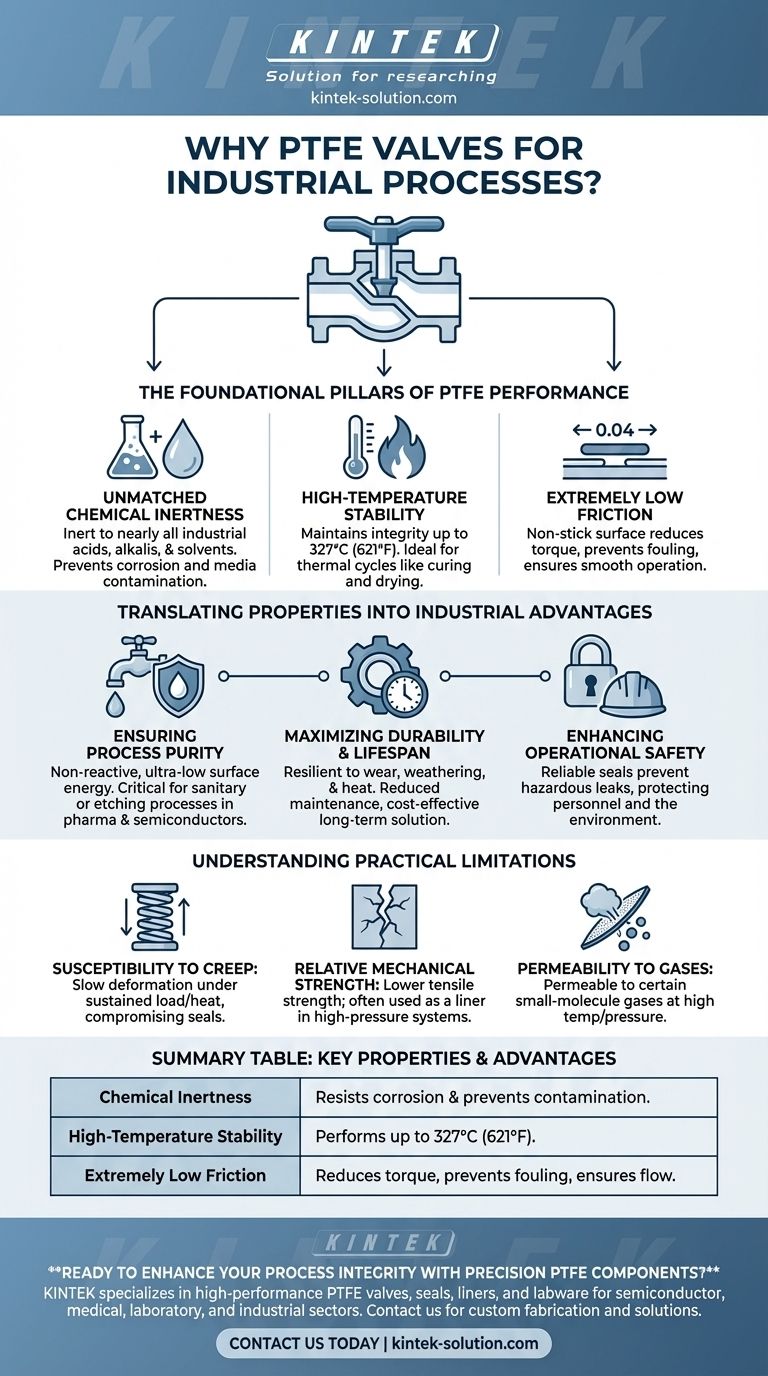

The Foundational Pillars of PTFE Performance

Understanding why PTFE (Polytetrafluoroethylene) is so effective requires looking at its core material science. These foundational properties are what translate into tangible industrial advantages.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. It is effectively inert to nearly all industrial acids, alkalis, and solvents.

This inertness means the valve's wetted parts will not corrode or degrade when exposed to aggressive media. More importantly, it ensures the material does not leach contaminants into the process fluid, which is critical for high-purity applications.

High-Temperature Stability

With a high melting point of 327°C (621°F), PTFE maintains its structural integrity and performance characteristics in high-temperature applications.

This makes it an ideal choice for processes involving curing, drying, or other thermal cycles where less resilient plastics would soften or decompose.

Extremely Low Friction

Commonly known by the trade name Teflon, PTFE has one of the lowest coefficients of friction of any solid, approximately 0.04. This creates a non-stick, low-friction surface.

In a valve, this means less torque is required for actuation, reducing wear on mechanical components. It also prevents process media from sticking to and fouling the valve's internal surfaces, ensuring smooth operation and consistent flow.

Translating Properties into Industrial Advantages

These fundamental properties are not just theoretical; they provide direct, measurable benefits in demanding operational environments.

Ensuring Process Purity

Because PTFE is non-reactive and has ultra-low surface energy, it is the material of choice for sanitary or etching processes.

Its non-stick surface resists the buildup of biological or chemical deposits, and its inert nature guarantees the purity of the liquid being transferred, a non-negotiable requirement in pharmaceuticals and semiconductor manufacturing.

Maximizing Durability and Lifespan

PTFE is a highly resilient plastic with excellent resistance to frictional wear, weathering, and heat. This inherent toughness contributes to a very long service life.

Valves made with or lined with PTFE require less frequent maintenance and replacement, providing a cost-effective and reliable long-term solution that enhances overall equipment durability.

Enhancing Operational Safety

The integrity of valve components like seals and packings is crucial for preventing leaks. Using high-quality PTFE is essential for containment.

By reliably preventing leaks of hazardous or corrosive chemicals, PTFE components protect personnel from exposure, prevent environmental contamination, and ensure the safety of the entire operation.

Understanding the Practical Limitations

While PTFE offers exceptional performance, it is critical to understand its trade-offs to ensure proper application. No single material is perfect for every scenario.

Susceptibility to Creep

Under a sustained mechanical load, especially at elevated temperatures, PTFE can be subject to "creep" or cold flow. This slow deformation can potentially compromise seal integrity over long periods.

Relative Mechanical Strength

Compared to metals, PTFE has lower tensile strength and rigidity. For this reason, in high-pressure systems, it is most often used as a robust liner inside a structural metal valve body (e.g., a PTFE-lined butterfly valve) rather than as the sole structural material.

Permeability to Certain Gases

While excellent with liquids, PTFE can be permeable to certain small-molecule gases, particularly at high temperatures and pressures. This must be considered in applications requiring perfect gas containment.

Making the Right Choice for Your Process

Your specific operational goal will determine which of PTFE's properties is most valuable.

- If your primary focus is process purity and sanitation: PTFE's inertness and non-stick surface are its most critical features, preventing media contamination and buildup.

- If your primary focus is handling aggressive chemicals: Its near-universal resistance to acids, bases, and solvents ensures valve longevity where metals would corrode.

- If your primary focus is long-term reliability and low maintenance: Its combination of durability, heat resistance, and low friction leads to an extended, trouble-free service life.

Ultimately, selecting PTFE valves is an investment in process stability, safety, and long-term operational efficiency.

Summary Table:

| Key Property | Industrial Advantage |

|---|---|

| Chemical Inertness | Resists corrosion & prevents media contamination from acids, alkalis, and solvents. |

| High-Temperature Stability | Maintains integrity and performance at temperatures up to 327°C (621°F). |

| Extremely Low Friction | Reduces actuation torque, prevents fouling, and ensures smooth, consistent flow. |

Ready to enhance your process integrity with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE valves, seals, liners, and labware. Our components are engineered to deliver the unmatched chemical resistance, thermal stability, and reliability your operations demand in the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific application.

Contact us today to discuss your requirements and discover how our PTFE solutions can safeguard your process, improve safety, and maximize your operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability