PTFE liners are commonly used in applications where extreme chemical resistance, low friction, and temperature stability are critical. They are a foundational component in industrial fluid handling systems like pipes and hoses, precision medical devices such as catheters, and high-purity equipment for the food and pharmaceutical industries.

The core reason for PTFE's widespread use is not a single property, but its unique combination of near-total chemical inertness, an extremely low coefficient of friction, and high-temperature tolerance. This makes it the default material for environments where virtually all other polymers would fail.

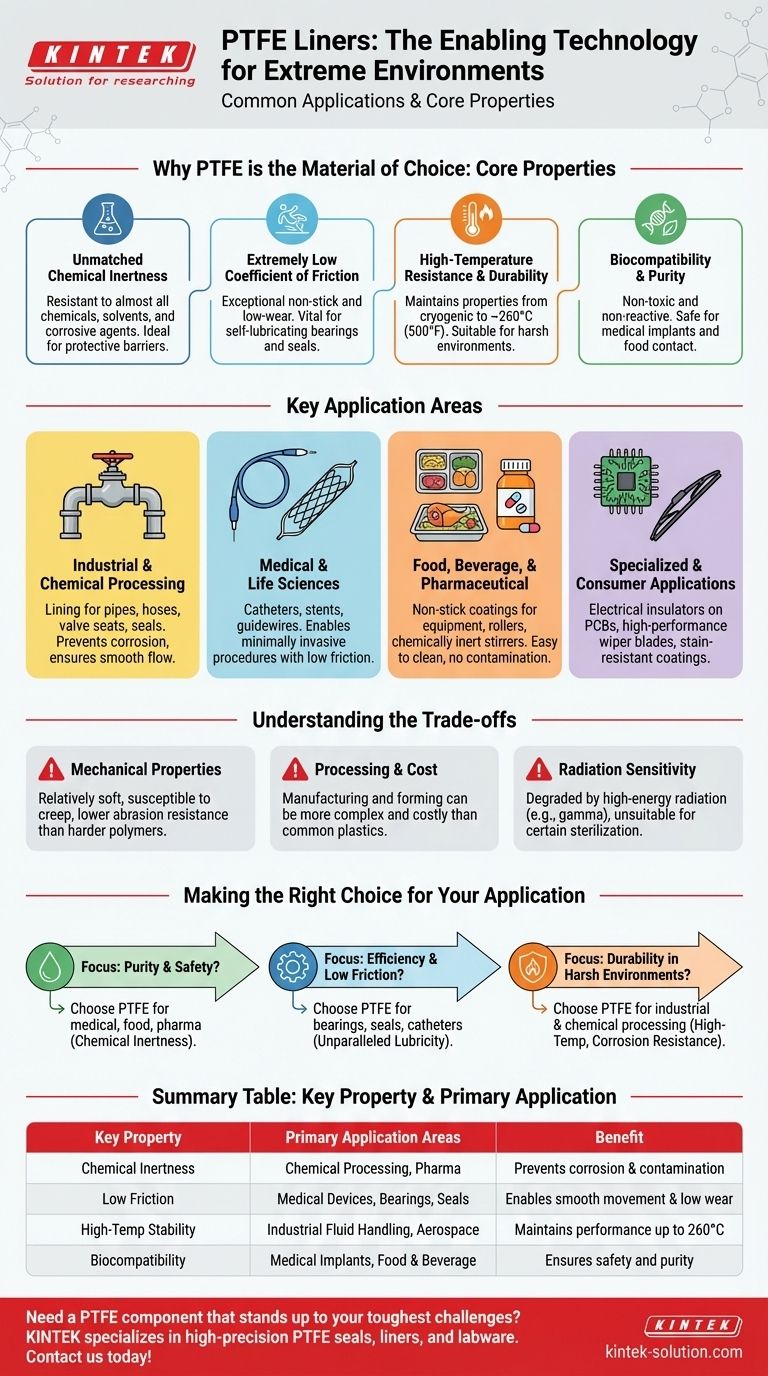

Why PTFE is the Material of Choice: The Core Properties

To understand its diverse applications, you must first understand the fundamental properties that make Polytetrafluoroethylene (PTFE) so effective. These characteristics work in concert to solve critical engineering challenges.

Unmatched Chemical Inertness

PTFE is resistant to almost all chemicals, solvents, and corrosive agents. This makes it an ideal protective barrier.

This property is essential in the chemical industry for lining vessels, tanks, and pipes that handle aggressive materials, preventing both corrosion of the equipment and contamination of the fluid.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it exceptional non-stick and low-wear characteristics.

This "slipperiness" is vital for applications like self-lubricating bearings, seals, and gaskets. In medicine, it allows catheters and guidewires to navigate complex pathways within the body with minimal resistance or damage to tissue.

High-Temperature Resistance and Durability

PTFE maintains its properties across a wide temperature range, from cryogenic levels up to approximately 260°C (500°F).

This thermal stability, combined with its durability, makes it suitable for high-temperature fluid handling, industrial bakeware, and components on external aircraft parts exposed to harsh environmental shifts.

Biocompatibility and Purity

PTFE is non-toxic and biocompatible, meaning it does not react with biological fluids or tissue.

This makes it a safe and reliable choice for medical implants, surgical tools like sutures, and any equipment that comes into contact with food, beverages, or pharmaceuticals.

Key Application Areas in Detail

These core properties translate directly into solutions for specific industries. While the list of uses is extensive, they can be grouped into several major categories.

Industrial and Chemical Processing

This is a primary domain for PTFE liners, where they protect equipment and ensure process integrity.

Common uses include lining for pipes, hoses, valve seats, and seals. The liner prevents corrosion from harsh chemicals and its non-stick surface ensures smooth, consistent flow of materials.

Medical and Life Sciences

In medicine, precision and reliability are non-negotiable. PTFE's properties make it a cornerstone material for advanced devices.

It is used extensively in catheters, stents, and guidewires, where its low friction allows for minimally invasive procedures. Its purity is also critical for use in syringes and other tools where contamination must be avoided.

Food, Beverage, and Pharmaceutical

Safety and purity are paramount in these industries. PTFE's non-toxic and non-stick nature is a significant advantage.

Applications include non-stick coatings for industrial cooking and baking equipment, rollers on conveyor belts, and chemically inert stirrers for bioprocessing. These surfaces are easy to clean and do not contaminate the product.

Specialized and Consumer Applications

The versatility of PTFE extends to many other high-performance sectors.

It serves as an excellent electrical insulator on printed circuit boards and is used in demanding consumer goods like high-performance wiper blades and stain-resistant coatings for fabrics.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. While powerful, PTFE has specific trade-offs that are important to consider.

Mechanical Properties

PTFE is a relatively soft material. It can be susceptible to "creep," or deformation under sustained pressure, and has lower abrasion resistance compared to harder polymers.

Processing and Cost

Manufacturing and forming PTFE components can be more complex and costly than working with more common plastics, which can impact project budgets.

Radiation Sensitivity

PTFE can be degraded by high-energy radiation, such as gamma or electron-beam radiation. This makes it unsuitable for certain sterilization methods or applications in high-radiation environments.

Making the Right Choice for Your Application

Your final decision depends on which of PTFE's properties is most critical for solving your specific challenge.

- If your primary focus is fluid purity and safety: PTFE's chemical inertness and non-toxic nature make it the superior choice for medical, food, and pharmaceutical applications.

- If your primary focus is mechanical efficiency and low friction: Its unparalleled lubricity is ideal for bearings, seals, and medical catheters where smooth, reliable movement is essential.

- If your primary focus is durability in harsh environments: Its resistance to extreme temperatures and corrosive agents makes it the go-to solution for demanding industrial and chemical processing.

Ultimately, PTFE's reliability in conditions that cause other materials to fail makes it less of a simple component and more of an enabling technology.

Summary Table:

| Key Property | Primary Application Areas | Benefit |

|---|---|---|

| Chemical Inertness | Chemical Processing, Pharma | Prevents corrosion & contamination |

| Low Friction | Medical Devices, Bearings, Seals | Enables smooth movement & low wear |

| High-Temp Stability | Industrial Fluid Handling, Aerospace | Maintains performance up to 260°C |

| Biocompatibility | Medical Implants, Food & Beverage | Ensures safety and purity |

Need a PTFE component that stands up to your toughest challenges? KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume order, our expertise ensures a solution that delivers unmatched chemical resistance, low friction, and thermal stability. Contact us today to discuss how we can support your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some modern applications of PTFE due to its electrical insulative properties? | High-Frequency & Extreme Environment Solutions

- What safety precautions are needed when machining Teflon? A Guide to Preventing Toxic Fumes

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are the advantages of molybdenum disulfide-filled PTFE? Boost Wear Resistance & Reduce Friction

- What makes PTFE gaskets suitable for cryogenic applications? Maintain a Reliable Seal at -200°C

- What are Labyrinth PTFE Seals and Bearing Isolators? Zero-Friction Sealing for High-Speed Equipment

- What are the key properties of PTFE washers? Ensure Reliability in Extreme Environments

- What factors should be considered when selecting Teflon O-rings? Solid vs. Encapsulated PTFE Seals