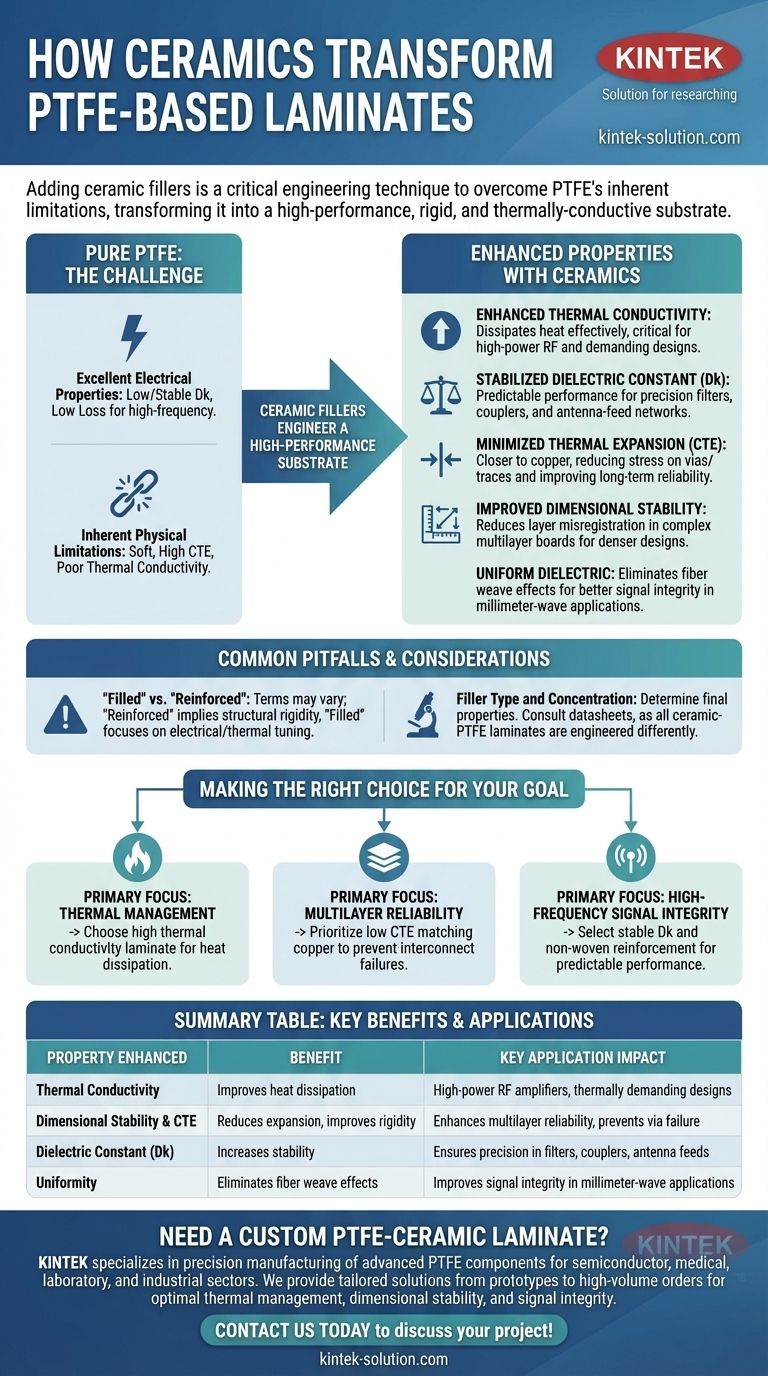

Adding ceramic fillers to PTFE-based laminates is a critical engineering technique used to overcome the inherent physical limitations of pure PTFE. These ceramics are introduced to systematically improve four key characteristics: thermal conductivity, dimensional stability, dielectric constant consistency, and the coefficient of thermal expansion (CTE).

The core purpose of adding ceramics to PTFE is to transform it from a soft, thermally-insulating material into a rigid, thermally-conductive, and dimensionally-stable substrate. This creates a composite material that retains PTFE's excellent high-frequency electrical properties while providing the physical robustness required for modern high-performance electronics.

The Challenge with Pure PTFE

To understand the role of ceramics, we must first recognize the fundamental trade-offs of using pure Polytetrafluoroethylene (PTFE) as a circuit laminate.

Excellent Electrical Properties

Pure PTFE is highly valued for its electrical characteristics. It has a very low and stable dielectric constant and extremely low loss, making it an ideal insulator for high-frequency applications.

Inherent Physical Limitations

However, pure PTFE is a soft material. It suffers from a high coefficient of thermal expansion (CTE) and poor thermal conductivity, making it unsuitable for applications requiring high reliability, complex multilayer designs, or significant heat dissipation.

How Ceramics Engineer a High-Performance Substrate

Ceramic fillers are not just additives; they are engineering tools used to precisely modify the properties of the PTFE base material.

Enhancing Thermal Conductivity

One of the most significant benefits is improved thermal conductivity. This allows heat generated by active components on the circuit board to be dissipated more effectively, which is critical for high-power RF amplifiers and other thermally demanding designs.

Stabilizing the Dielectric Constant (Dk)

Ceramics help create a composite with a more stable dielectric constant over a wide range of temperatures and frequencies. This predictability is essential for designing precision filters, couplers, and antenna-feed networks where performance depends on consistent material properties.

Minimizing Thermal Expansion (CTE)

Ceramics drastically lower the CTE of the laminate, bringing it much closer to that of copper. This minimizes the stress on plated through-holes and copper traces during thermal cycling, vastly improving the long-term reliability of the device.

Improving Dimensional Stability

By lowering the CTE and adding rigidity, ceramics significantly improve the material's dimensional stability. This reduces layer-to-layer misregistration during the manufacturing of complex multilayer boards, enabling denser and more reliable designs.

Eliminating Fiber Weave Effects

Unlike glass-fiber reinforcements, ceramic fillers or reinforcements do not have a weave structure. This creates a more uniform dielectric medium, eliminating the signal integrity issues caused by fiber weave effects in very high-frequency (millimeter-wave) applications.

Common Pitfalls to Avoid

While highly beneficial, selecting a ceramic-PTFE laminate requires careful consideration of the details.

'Filled' vs. 'Reinforced'

Vendors may use the terms "ceramic-filled" and "ceramic-reinforced" interchangeably. While both improve properties, a "reinforced" material often implies a greater focus on structural rigidity, whereas "filled" may focus more on tuning electrical or thermal characteristics.

Filler Type and Concentration

The specific type of ceramic and its concentration in the PTFE matrix determine the final properties. Not all ceramic-PTFE laminates are the same; they are engineered for different performance targets. Always consult the material datasheet for specific values.

Making the Right Choice for Your Goal

Your application's primary need should guide your material selection.

- If your primary focus is thermal management: Choose a laminate specifically engineered for high thermal conductivity to ensure effective heat dissipation from power components.

- If your primary focus is multilayer reliability: Prioritize a material with a low CTE that closely matches copper to prevent interconnect failures during thermal cycling.

- If your primary focus is high-frequency signal integrity: Select a material with a highly stable dielectric constant and a non-woven reinforcement to ensure predictable circuit performance.

By understanding these principles, you can confidently select the right material to meet the specific demands of your design.

Summary Table:

| Property Enhanced by Ceramics | Benefit for PTFE Laminate | Key Application Impact |

|---|---|---|

| Thermal Conductivity | Improves heat dissipation | Enables high-power RF amplifiers and thermally demanding designs |

| Dimensional Stability & CTE | Reduces expansion, improves rigidity | Enhances multilayer reliability and prevents via failure |

| Dielectric Constant (Dk) | Increases stability over temperature/frequency | Ensures precision in filters, couplers, and antenna feeds |

| Uniformity | Eliminates fiber weave effects | Improves signal integrity in millimeter-wave applications |

Need a custom PTFE-ceramic laminate for your high-performance application?

KINTEK specializes in precision manufacturing of advanced PTFE components, including custom laminates with ceramic fillers for the semiconductor, medical, laboratory, and industrial sectors. We provide tailored solutions from prototypes to high-volume orders, ensuring optimal thermal management, dimensional stability, and signal integrity for your designs.

Contact us today to discuss your project requirements and leverage our expertise in material engineering!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is specialized equipment needed for PTFE impeller manufacturing? Precision Machining for Critical Performance

- What regulatory standards do Medical Grade PTFE Liners meet? Ensuring FDA & ISO Compliance for Patient Safety

- Where are PTFE energized seals typically used in cryogenic applications? Critical Seals for LNG & Aerospace

- What types of fillers are commonly used in PTFE? Enhance Performance for Demanding Applications

- Why are PTFE expansion bellows preferred in the food and beverage industry? Ensure Purity and Safety

- What are the main differences between PTFE lined butterfly valves and hard seal butterfly valves? Choose the Right Seal for Your Application

- What are the benefits of using Teflon encapsulated silicone o-rings? Achieve Unmatched Sealing in Harsh Environments

- How do PTFE-lined diaphragm valves contribute to cost savings? Reduce Operational Costs & Downtime