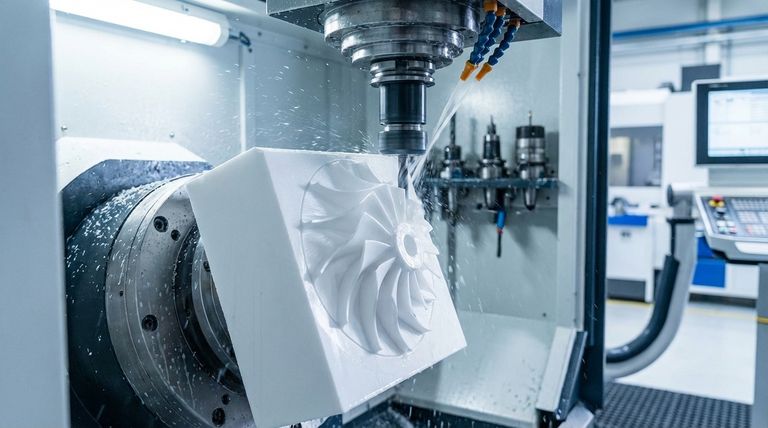

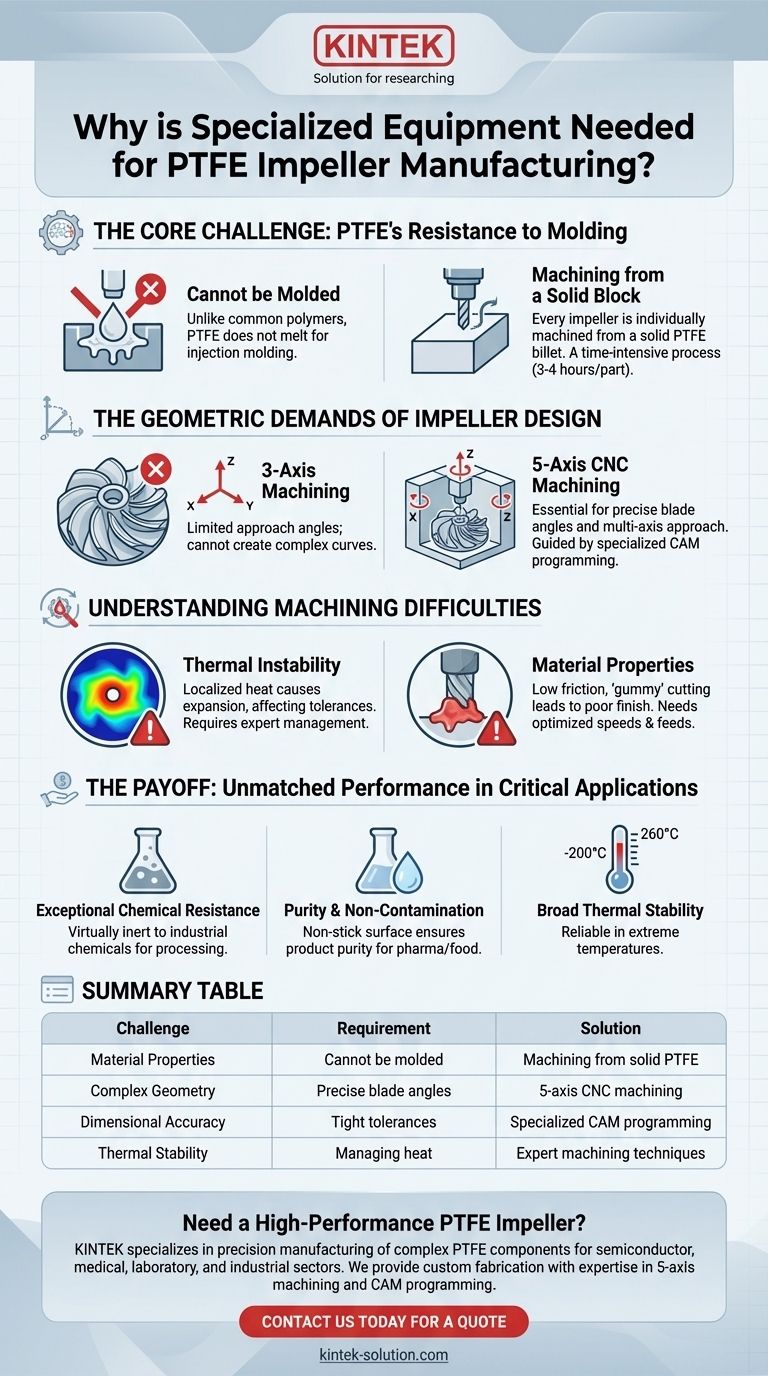

Manufacturing PTFE impellers requires specialized equipment because the material cannot be molded like other plastics, and the part's complex geometry demands advanced machining. Each impeller must be individually carved from a solid block of PTFE using high-precision, 5-axis machinery guided by specialized CAM programming to achieve the necessary blade angles and dimensional accuracy.

The core issue is twofold: PTFE's unique material properties prevent traditional, high-volume manufacturing methods like injection molding, while the functional design of an impeller is too geometrically complex for simple machining tools. This combination makes specialized, high-precision machining the only viable production path.

The Core Challenge: PTFE's Resistance to Molding

Unlike common polymers that can be melted and injected into molds for mass production, PTFE (Polytetrafluoroethylene) behaves differently. This fundamental material property is the first barrier to simple manufacturing.

Machining from a Solid Block

Because it cannot be molded, every single PTFE impeller must be machined from a solid billet or block of the material. This is an inherently subtractive, and therefore slower, process.

A Time-Intensive Process

This method is incredibly time-consuming, often taking three to four hours to produce a single impeller. This makes scaling production a significant operational and financial challenge without the right equipment and expertise.

The Geometric Demands of Impeller Design

An impeller's function is to move fluid efficiently. This requires a specific and complex three-dimensional shape that simple tools cannot create.

The Necessity of Complex Blade Angles

The blades of an impeller are not flat; they feature precise curves and angles designed for optimal hydraulic performance. These geometries are critical to the component's function.

The Role of 5-Axis Machining

Standard 3-axis machines move on the X, Y, and Z axes. A 5-axis machine can also rotate the tool and the workpiece, allowing it to approach the material from virtually any angle. This capability is essential to accurately carve the complex, curved surfaces of impeller blades.

Precision through CAM Programming

Achieving the required dimensional accuracy is impossible without specialized Computer-Aided Manufacturing (CAM) software. This software translates the digital design into precise, multi-axis toolpaths for the machine to follow.

Understanding the Trade-offs: Why PTFE is So Difficult to Machine

Even with the right equipment, PTFE itself presents significant machining challenges that require deep expertise in both machining and polymer science.

Thermal Instability During Machining

While PTFE is stable across a wide service temperature range, the localized heat from a cutting tool can cause it to expand or deform. This can ruin dimensional tolerances if not managed by an expert machinist.

Material Properties

PTFE has a very low coefficient of friction and does not chip cleanly like metal. It can become "gummy" during cutting, leading to a poor surface finish and tool buildup if speeds, feeds, and tool geometry are not perfectly optimized.

The Payoff: Unmatched Performance in Critical Applications

The complex manufacturing process is justified by PTFE's extraordinary properties, which make it indispensable in demanding industries.

Exceptional Chemical Resistance

PTFE is virtually inert, capable of handling almost all industrial chemicals without degrading. This makes it essential for chemical processing and aggressive fluid handling.

Purity and Non-Contamination

Its non-stick surface prevents material buildup, ensuring product purity. This is a non-negotiable requirement in pharmaceutical and food and beverage manufacturing.

Broad Thermal Stability

PTFE maintains its integrity in extreme temperatures, from -200°C to 260°C, providing reliability where other materials would fail.

Making the Right Choice for Your Application

Understanding the manufacturing constraints of PTFE allows you to make an informed decision when specifying components for your system.

- If your primary focus is handling highly corrosive chemicals: The manufacturing complexity is justified by PTFE's unparalleled chemical inertness.

- If your primary focus is ensuring absolute product purity: The non-stick, non-contaminating surface of a precisely machined PTFE impeller is the only reliable choice.

- If your primary focus is a low-cost, general-purpose application: You should evaluate whether a more easily manufactured material can meet your less stringent operational requirements.

Ultimately, recognizing why PTFE impellers require such a specialized process is key to specifying and sourcing the right component for your critical application.

Summary Table:

| Challenge | Requirement | Solution |

|---|---|---|

| Material Properties (Cannot be molded) | Machining from solid PTFE | Subtractive manufacturing from billet |

| Complex Geometry | Precise blade angles and curves | 5-axis CNC machining |

| Dimensional Accuracy | Tight tolerances for performance | Specialized CAM programming |

| Thermal Stability | Managing heat during cutting | Expert machining techniques |

Need a high-performance PTFE impeller for your critical application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including complex impellers for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in 5-axis machining and CAM programming ensures your impeller meets the exact geometric and performance requirements your application demands.

We provide custom fabrication from prototypes to high-volume orders, guaranteeing the chemical resistance, purity, and thermal stability you need.

Contact us today to discuss your PTFE impeller requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability