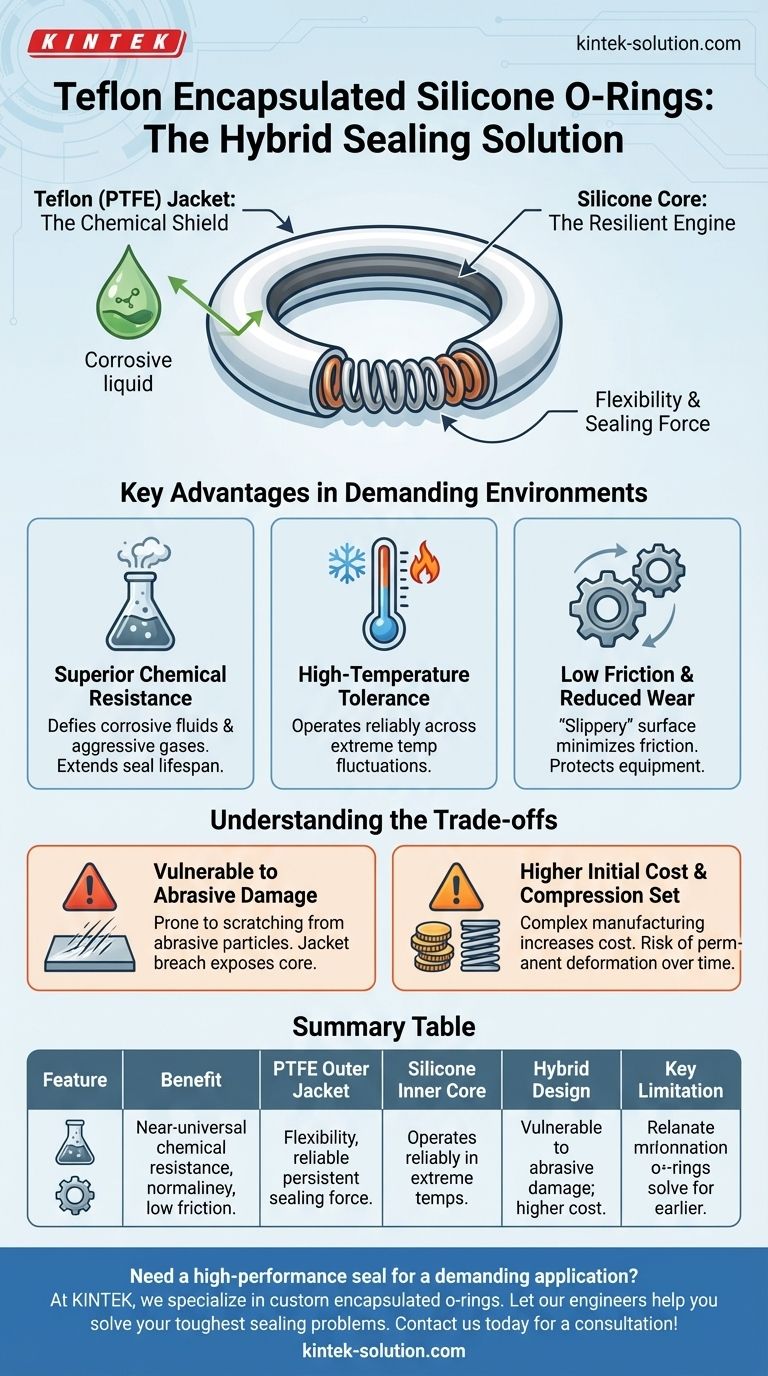

In essence, Teflon encapsulated silicone o-rings provide a unique combination of extreme chemical and temperature resistance from a Teflon outer jacket, coupled with the flexibility and reliable sealing force of an inner silicone core. This hybrid design allows them to perform in harsh environments where a standard elastomer or a rigid, solid Teflon ring would fail.

These o-rings are a specialized sealing solution designed to solve a fundamental trade-off. They merge the near-universal chemical inertness of PTFE (Teflon) with the essential elasticity of silicone, creating a high-performance seal for demanding applications.

The Core Principle: A Two-Part Solution

The exceptional performance of these o-rings comes from their composite structure. They are not a single material but a clever engineering solution combining two distinct components.

The Teflon (PTFE) Jacket: The Chemical Shield

The outer layer is a thin, seamless jacket of PTFE, commonly known as Teflon. This jacket is the component that directly contacts the system fluids and surfaces.

Its primary role is to provide virtual chemical immunity. PTFE is inert to almost all industrial chemicals and solvents, preventing degradation that would destroy a standard elastomer.

The Silicone Core: The Resilient Engine

Inside the jacket lies a core of silicone elastomer. While the Teflon provides chemical protection, it is a rigid material with poor memory, meaning it doesn't spring back into shape after being compressed.

The silicone core acts as a spring, providing the flexibility and persistent sealing force necessary to maintain a tight seal, even with fluctuations in pressure and temperature.

Key Advantages in Demanding Environments

This dual-material design translates into tangible benefits for critical industrial and automotive applications.

Superior Chemical Resistance

The PTFE jacket ensures the seal can withstand corrosive fluids and aggressive gases that would cause premature failure in standard o-rings. This significantly extends the seal's lifespan and reduces costly downtime.

High-Temperature Tolerance

The combination of a silicone core and a Teflon jacket allows these o-rings to operate reliably across a very wide temperature range, handling conditions that are too extreme for many other sealing materials.

Low Friction and Reduced Wear

Teflon is known for its extremely low coefficient of friction. This "slippery" surface minimizes friction against moving parts, which reduces wear on both the seal and the equipment it protects.

Understanding the Trade-offs and Limitations

While powerful, this technology is not a universal solution. An objective assessment requires understanding its inherent limitations.

Vulnerability to Abrasive Damage

The thin Teflon jacket, while chemically tough, is mechanically soft. It is prone to scratching and damage in environments with abrasive particles or rough mating surfaces. Any breach in the jacket compromises the entire seal by exposing the vulnerable silicone core.

Higher Initial Cost

The complex, multi-step manufacturing process makes encapsulated o-rings significantly more expensive than standard single-material o-rings. This cost must be justified by the need for enhanced performance and longer service life.

The Risk of Compression Set

While the silicone core provides elasticity, the Teflon jacket can be susceptible to "compression set," a permanent deformation that occurs after being compressed for a long time, especially at high temperatures. This can eventually lead to leaks.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its characteristics to the specific demands of your system.

- If your primary focus is sealing against aggressive chemicals in a low-abrasion environment: An encapsulated o-ring is an excellent choice, offering superior protection and longevity.

- If your primary focus is managing high temperatures without harsh chemicals: A high-grade silicone or FKM o-ring might be a more cost-effective solution.

- If your primary focus is a high-wear or abrasive application: You must carefully consider if the Teflon jacket can withstand the mechanical stress, as damage will lead to rapid failure.

Ultimately, choosing an encapsulated o-ring is an engineering decision that balances extreme resistance against mechanical fragility and cost.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Outer Jacket | Provides near-universal chemical resistance and low friction. |

| Silicone Inner Core | Ensures flexibility and a reliable, persistent sealing force. |

| Hybrid Design | Operates reliably in extreme temperatures where standard seals fail. |

| Key Limitation | Vulnerable to abrasive damage; higher initial cost. |

Need a high-performance seal for a demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom encapsulated o-rings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly tailored to withstand your specific chemical, temperature, and pressure challenges.

Let our engineers help you solve your toughest sealing problems. Contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech