In cryogenic environments, PTFE energized seals are most typically used in mission-critical applications where failure is not an option. You will find them in the transportation of liquefied natural gas (LNG), specifically in loading arms and transfer systems, and in aeronautics for handling highly reactive propellants and hypergolic fluids.

The core reason for their use is simple: PTFE energized seals provide a reliable, dynamic seal when other materials fail. The combination of PTFE's extreme temperature tolerance and chemical inertness, powered by a spring that compensates for thermal contraction, makes it a default choice for sealing aggressive fluids at temperatures approaching -200°C.

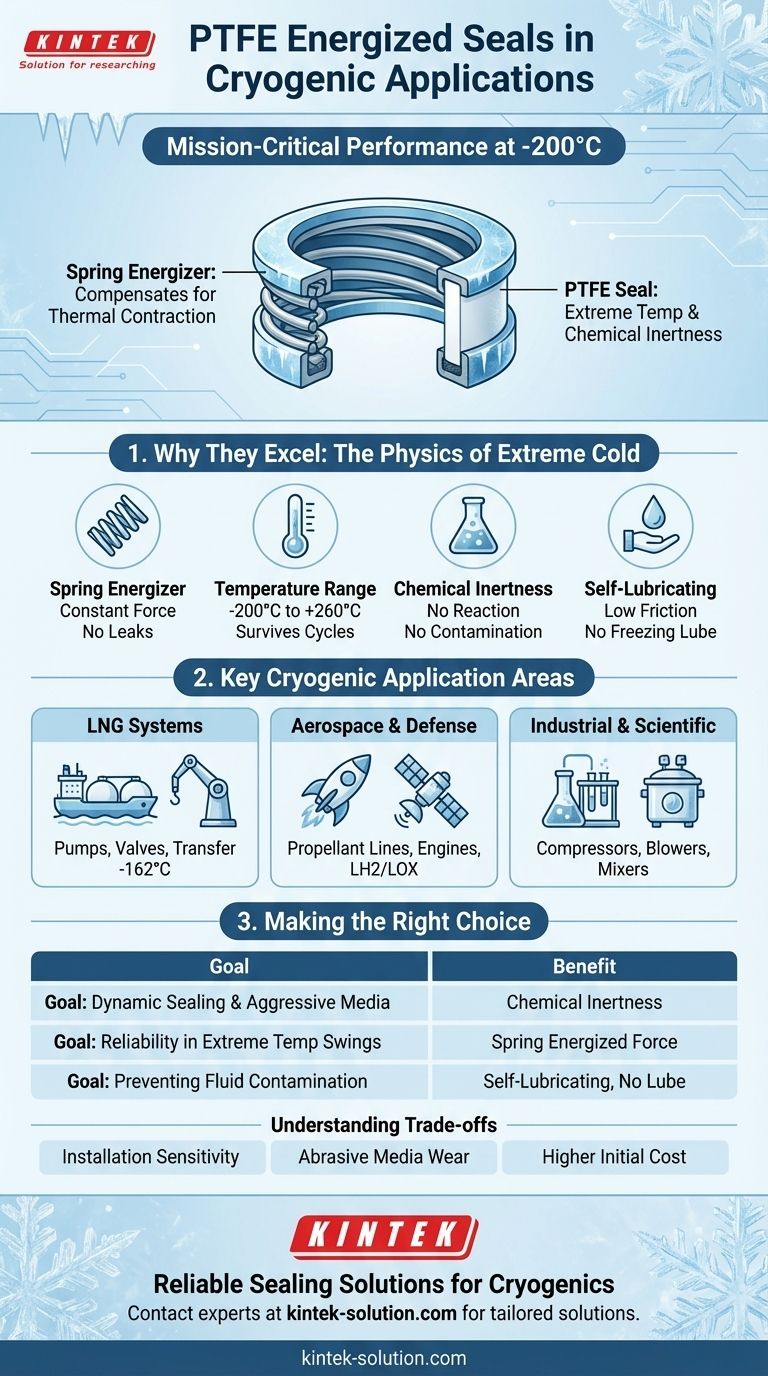

Why PTFE Energized Seals Excel in Cryogenics

To understand where these seals are used, it's essential to first understand why they are uniquely suited for the physics of extreme cold. Standard elastomeric seals often become brittle and fail, but the design of a PTFE energized seal directly addresses these challenges.

The Critical Role of the Spring Energizer

At cryogenic temperatures, all materials shrink. A metal housing will contract at a different rate than a polymer seal, creating a potential leak path.

The internal spring is the key. It acts as a constant energy source, pushing the PTFE seal lips firmly against the sealing surfaces, regardless of dimensional changes caused by the extreme cold.

Surviving Extreme Cold and Heat

PTFE as a material has an exceptionally wide operating temperature range, remaining functional from approximately -200°C to +260°C.

This means the same seal can often handle cryogenic fluids and then potentially high-temperature system cleaning or sterilization cycles without degradation.

Inherent Chemical Inertness

Many cryogenic fluids, particularly in aerospace, are highly reactive propellants. PTFE is one of the most chemically inert materials known.

It will not react with or contaminate the media it is sealing, which is a critical safety and purity requirement in applications involving liquid oxygen, hydrogen, or other specialized fluids.

No Need for External Lubrication

Most lubricants would freeze, solidify, and become useless at cryogenic temperatures.

PTFE has an extremely low coefficient of friction, making it naturally "self-lubricating." This allows it to perform in dynamic applications like rotating shafts or reciprocating rods without requiring an external lubricant.

Key Cryogenic Application Areas

Based on these principles, PTFE energized seals are specified for systems where performance and safety are paramount.

Liquefied Natural Gas (LNG) Systems

The global transport of LNG relies on keeping the gas in its liquid state at approximately -162°C (-260°F).

These seals are found in pumps, valves, and the articulated loading arms that transfer LNG between production facilities, transport ships, and regasification terminals.

Aerospace and Defense

Rocket propulsion and satellite systems often depend on cryogenic fluids.

Applications include seals for valves in propellant lines, engine fuel systems, and hydraulic actuators that must function reliably in the cold of space or during engine operation with liquid hydrogen (LH2) and liquid oxygen (LOX).

Industrial and Scientific Equipment

Beyond bulk transport, these seals are used in specialized equipment across various industries.

This includes cryogenic compressors, blowers, mixers, and scientific instrumentation that utilize liquid nitrogen or other cryogens for cooling or processing.

Understanding the Trade-offs

While highly effective, PTFE energized seals are a specialized solution, and it's important to understand their limitations.

Installation Sensitivity

The PTFE jacket is softer than a metal housing. Care must be taken during installation to avoid scratching or nicking the seal lip, as even minor damage can create a leak path.

Performance in Abrasive Media

PTFE is a relatively soft material. If the cryogenic fluid contains abrasive particles (such as debris in a hydraulic system), the life of the seal can be significantly reduced due to wear on the seal lip.

Higher Initial Cost

As a high-performance, precision component, a PTFE energized seal typically has a higher upfront cost than a standard O-ring or elastomeric seal. This cost is justified by its performance and reliability in applications where standard seals would fail.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching its core strengths to your primary engineering challenge.

- If your primary focus is dynamic sealing with aggressive media: PTFE's chemical inertness makes it the superior choice for handling reactive cryogenic propellants or ultra-pure industrial gases.

- If your primary focus is reliability across extreme temperature swings: The spring energizer ensures a consistent seal force, compensating for the thermal contraction and expansion inherent in cryogenic systems.

- If your primary focus is preventing fluid contamination: The self-lubricating nature of PTFE eliminates the need for external lubricants that could freeze, fail, or contaminate the cryogenic fluid.

Ultimately, understanding these core principles empowers you to specify a sealing solution that ensures both safety and performance in the demanding world of cryogenics.

Summary Table:

| Application Area | Key Uses | Primary Benefit |

|---|---|---|

| LNG Systems | Loading arms, pumps, valves | Reliable sealing at -162°C for safe transport |

| Aerospace & Defense | Propellant valves, fuel systems | Chemical inertness for reactive fluids like LOX/LH2 |

| Industrial/Scientific | Cryogenic compressors, mixers | Self-lubricating, no external lubricants needed |

Need a reliable sealing solution for your cryogenic application? KINTEK specializes in manufacturing high-performance PTFE components, including energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure your systems perform safely and efficiently, even at extreme temperatures. Contact our experts today to discuss your specific requirements and get a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry