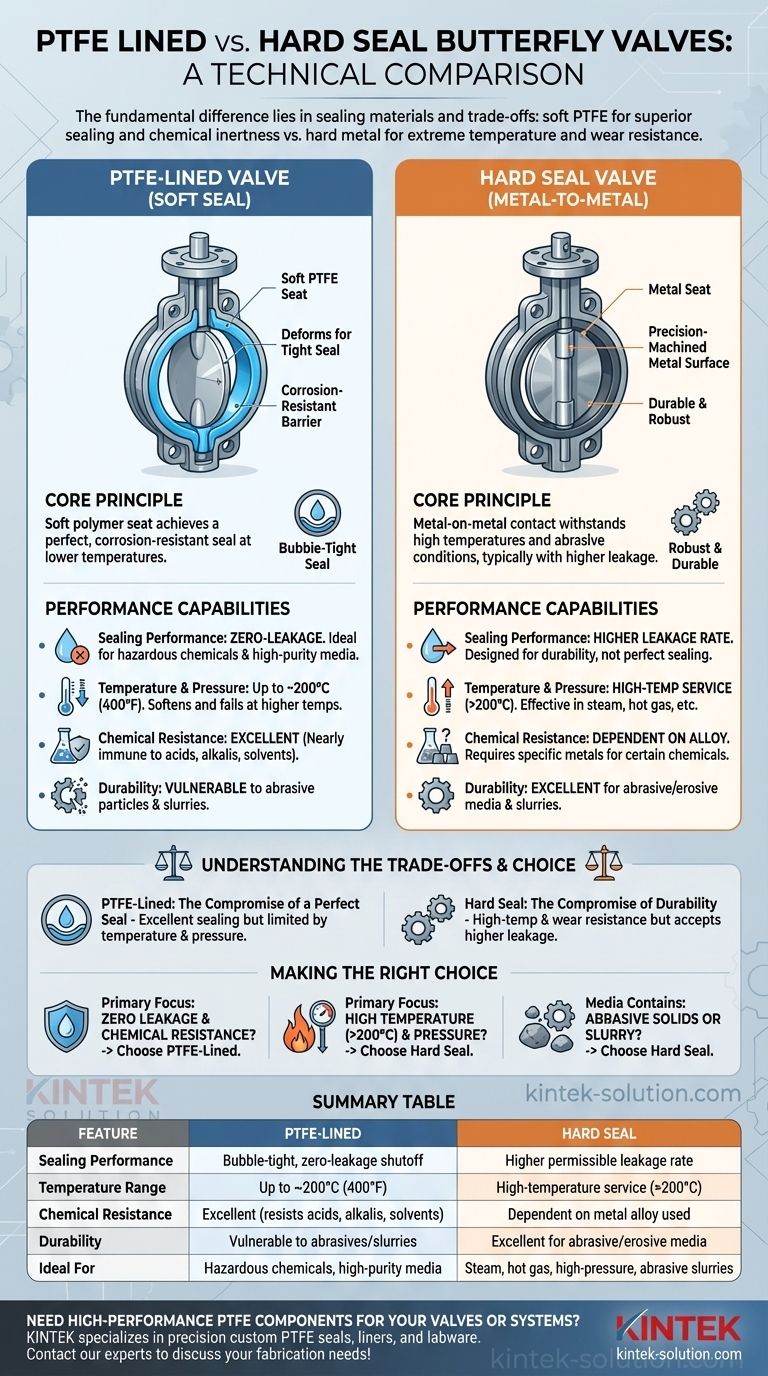

The fundamental difference between PTFE-lined and hard seal butterfly valves lies in their sealing materials and the trade-offs they create. PTFE-lined valves use a soft polymer seat to achieve a perfect, corrosion-resistant seal at lower temperatures, whereas hard seal valves use metal-on-metal contact to withstand high temperatures and abrasive conditions, typically sacrificing a zero-leak shutoff.

The choice is not about which valve is "better," but which is correct for the operating environment. You are choosing between the superior sealing and chemical inertness of a soft PTFE seal and the extreme temperature and wear resistance of a hard metal seal.

Deconstructing the Sealing Mechanism

To understand the performance differences, you must first visualize how each valve achieves shutoff. The design of the seal dictates every other characteristic of the valve.

PTFE-Lined Valves: The Soft Seal Principle

PTFE (polytetrafluoroethylene) is a soft, non-metallic polymer. In a PTFE-lined valve, the disc closes against this soft seat.

The material’s pliability allows it to deform slightly under pressure, filling any microscopic imperfections between the disc and the body. This creates an exceptionally tight, often bubble-tight, seal.

As a chemically inert fluoropolymer, the PTFE lining also serves as a protective barrier, isolating the valve's metal body from corrosive or reactive media.

Hard Seal Valves: The Metal-to-Metal Principle

Hard seal valves, often called metal-seated valves, feature a disc and a seat made from hard materials, typically stainless steel or other durable metal alloys.

These sealing surfaces are precision-machined to fit together as perfectly as possible. However, because metal does not deform like a soft polymer, achieving a zero-leak seal is extremely difficult and often not the design goal.

Their strength lies in the inherent durability of metal, which can maintain its structural integrity under conditions that would destroy a soft seal.

Comparing Core Performance Characteristics

The differences in sealing design lead to starkly different performance capabilities. Your application's demands will point clearly to one type or the other.

Sealing Performance

A PTFE-lined valve is designed for zero-leakage shutoff. Its soft seat excels at creating a positive seal, which is critical in applications involving hazardous chemicals, high-purity media, or processes where any leakage is unacceptable.

A hard seal valve is designed for durability, not perfect sealing. It will almost always have a higher permissible leakage rate than a soft-seated valve. This is an accepted operational trade-off for its other benefits.

Temperature and Pressure Range

PTFE has a distinct operational temperature limit, typically around 200°C (400°F). Beyond this, the material begins to soften and fail.

Hard seal valves are the default choice for high-temperature and high-pressure service. Because they are constructed from metal, they can operate effectively in applications like steam, hot gas, or thermal fluids where temperatures far exceed the limits of any polymer.

Corrosion and Chemical Resistance

PTFE is nearly immune to chemical attack, making it the ideal choice for highly corrosive media like strong acids, alkalis, and solvents. The lining effectively protects the valve's core components from the process fluid.

The corrosion resistance of a hard seal valve is entirely dependent on the specific metal alloy used in its construction. While materials like stainless steel offer good general resistance, they can still be attacked by specific chemicals, requiring more exotic and expensive alloys.

Durability and Wear Resistance

The softness of a PTFE seal makes it vulnerable to damage from abrasive particles or slurries in the media. High-velocity flow can also cause erosion over time.

Hard seal valves excel in abrasive or erosive service. The metal-on-metal design is inherently more robust and can withstand particulate matter that would quickly destroy a soft polymer seat.

Understanding the Trade-offs

Selecting the wrong valve can lead to premature failure, process contamination, or safety hazards. Understanding the inherent compromises is key to avoiding these issues.

The Compromise of a Perfect Seal

Choosing a PTFE-lined valve for its bubble-tight seal means you must accept its limitations in temperature, pressure, and resistance to abrasive media. Exceeding these limits will cause the seal to fail.

The Compromise of Durability

Opting for a hard seal valve for its high-temperature durability means you must design your system to tolerate a certain amount of seat leakage. It is not the right choice for applications requiring absolute shutoff.

Lifespan and Failure Modes

A PTFE-lined valve in the correct service can have a long lifespan, but it will eventually fail due to material wear or degradation. A hard seal valve is more likely to fail due to galling (wear between sliding metal surfaces) or a gradual increase in leakage rate over time.

Making the Right Choice for Your Application

Base your decision on the non-negotiable demands of your specific service conditions.

- If your primary focus is zero leakage and/or extreme chemical resistance: A PTFE-lined valve is the only suitable choice.

- If your primary focus is high-temperature (>200°C) or high-pressure service: You must use a hard seal butterfly valve.

- If your media contains abrasive solids or is a slurry: A hard seal valve will provide a much longer and more reliable service life.

Ultimately, choosing the right butterfly valve comes from correctly identifying the most demanding aspect of your application and selecting the material designed to master it.

Summary Table:

| Feature | PTFE-Lined Butterfly Valve | Hard Seal Butterfly Valve |

|---|---|---|

| Sealing Performance | Bubble-tight, zero-leakage shutoff | Higher permissible leakage rate |

| Temperature Range | Up to ~200°C (400°F) | High-temperature service (>200°C) |

| Chemical Resistance | Excellent (resists acids, alkalis, solvents) | Dependent on metal alloy used |

| Durability | Vulnerable to abrasives/slurries | Excellent for abrasive/erosive media |

| Ideal For | Hazardous chemicals, high-purity media | Steam, hot gas, high-pressure, abrasive slurries |

Need High-Performance PTFE Components for Your Valves or Systems?

Choosing the right seal material is critical for your valve's performance, longevity, and safety. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—including custom seals, liners, and labware—that deliver the superior chemical resistance and reliable sealing your applications demand.

Whether you require prototypes or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your components meet exact specifications. Let us help you solve your most challenging fluid handling problems.

Contact our experts today to discuss your custom PTFE fabrication needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts