PTFE-lined diaphragm valves generate significant cost savings by minimizing long-term operational expenses. Their robust design directly reduces the frequency of maintenance, replacement, and costly system downtime. By preventing leaks and resisting chemical attack, they protect valuable products and ensure process integrity over the valve's extended lifespan.

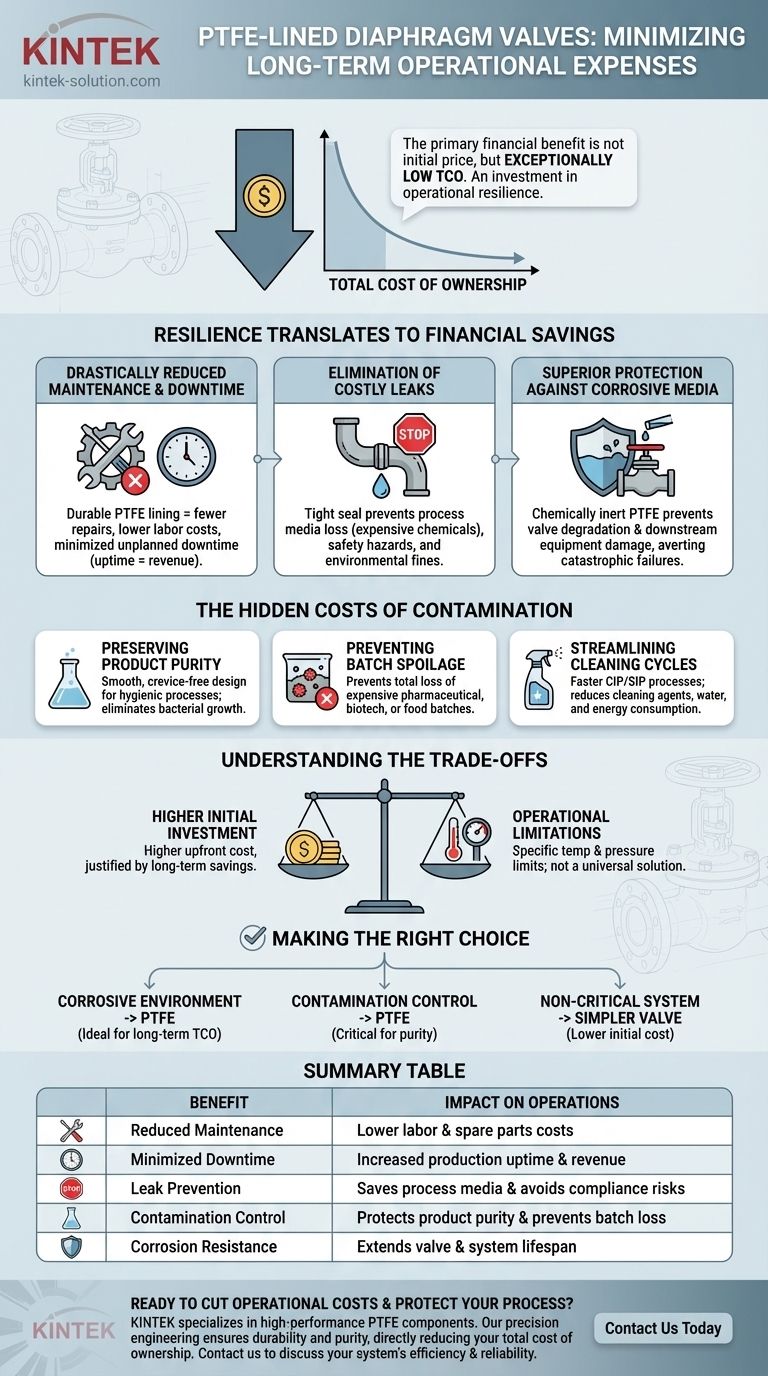

The primary financial benefit of a PTFE-lined diaphragm valve is not its initial price, but its exceptionally low total cost of ownership. It is an investment in operational resilience, designed to prevent the far greater costs associated with maintenance, downtime, and product loss in demanding environments.

How Resilience Translates to Financial Savings

The core value of these valves lies in their ability to withstand conditions that cause lesser components to fail. This durability is the foundation of their economic advantage.

Drastically Reduced Maintenance and Downtime

The durability of the PTFE lining and its resistance to wear mean the valve requires far less frequent servicing. Fewer repairs translate directly into lower labor costs and reduced spending on spare parts.

Most importantly, this reliability minimizes unplanned downtime. In a production environment, every hour the system is offline represents lost revenue, making uptime the most critical factor in operational profitability.

Elimination of Costly Leaks

PTFE-lined diaphragm valves are engineered to provide a tight, consistent seal. This prevents the gradual loss of process media, which can represent a significant material cost over time, especially when dealing with expensive chemicals.

Furthermore, containing aggressive fluids prevents potential safety hazards and environmental compliance issues, which carry their own substantial financial risks.

Superior Protection Against Corrosive Media

PTFE is virtually inert to most industrial chemicals. This resistance prevents the valve itself from degrading, which avoids the need for frequent replacement.

This chemical barrier also protects the entire system. By containing corrosive media effectively, the valve helps prevent downstream equipment damage, averting catastrophic failures and expensive, system-wide repairs.

The Hidden Costs of Contamination

In industries where purity is paramount, the design of a valve is just as important as its material. Preventing contamination is a direct form of cost control.

Preserving Product Purity

The smooth, no-pocket, and crevice-free design of these valves is ideal for hygienic processes. It eliminates areas where bacteria can grow or old batches can linger, ensuring the purity of the final product.

Preventing Batch Spoilage

In pharmaceutical, biotech, and food and beverage manufacturing, a single contaminated batch can result in a total loss, costing thousands or even millions of dollars. The valve acts as a critical control point to prevent this type of catastrophic financial event.

Streamlining Cleaning Cycles

The low-adhesion properties of PTFE and the valve's simple internal geometry make Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes faster and more effective. This reduces the consumption of cleaning agents, water, and energy, lowering operational overhead.

Understanding the Trade-offs

While highly effective, these valves are a specialized solution. Objectivity requires acknowledging their limitations to ensure proper application.

Higher Initial Investment

PTFE-lined diaphragm valves typically have a higher upfront purchase price compared to simpler valves made from less resilient materials. The cost justification is based entirely on long-term savings rather than initial outlay.

Operational Limitations

PTFE has specific temperature and pressure limits. In applications that exceed these ratings, other valve technologies may be required. They are a superior choice within their operational window, not a universal solution for every extreme condition.

Application Specificity

In simple, non-corrosive, and non-hygienic applications (such as basic water transport), the advanced features of a PTFE-lined valve would be unnecessary. Using them in such a scenario would be an over-investment without a clear financial return.

Making the Right Choice for Your System

Selecting the correct valve is about aligning the component's strengths with your primary operational goal.

- If your primary focus is minimizing long-term operational costs in a corrosive environment: This valve is the ideal choice, as its durability will pay for itself through reduced maintenance and downtime.

- If your primary focus is preventing product contamination and ensuring purity: The hygienic, non-reactive design of this valve is a critical tool for risk management in pharmaceutical or food-grade applications.

- If your primary focus is the lowest possible initial cost for a non-critical system: A simpler, less specialized valve may be a more appropriate financial decision for handling non-aggressive media.

Ultimately, choosing the right valve is an investment in the long-term financial health and stability of your process.

Summary Table:

| Cost-Saving Benefit | Impact on Operations |

|---|---|

| Reduced Maintenance | Lower labor & spare parts costs |

| Minimized Downtime | Increased production uptime & revenue |

| Leak Prevention | Saves expensive process media & avoids compliance risks |

| Contamination Control | Protects product purity & prevents batch loss |

| Corrosion Resistance | Extends valve & system lifespan, avoiding replacements |

Ready to cut your operational costs and protect your process? KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE-lined valves, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures durability and purity, directly reducing your total cost of ownership. Contact us today to discuss how our PTFE solutions can enhance your system's efficiency and reliability—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry