In the food and beverage industry, PTFE expansion bellows are preferred because their unique combination of properties directly addresses the sector's most critical requirements: absolute hygiene, product purity, and process reliability. They are certified as safe for food contact, possess a non-stick surface that prevents residue buildup, and are chemically inert, ensuring they do not contaminate the products they handle.

The core reason for PTFE's dominance is not a single feature, but its holistic ability to mitigate risk. It simultaneously prevents microbial contamination, chemical leaching, and material degradation, making it the definitive choice for protecting both the product and the consumer.

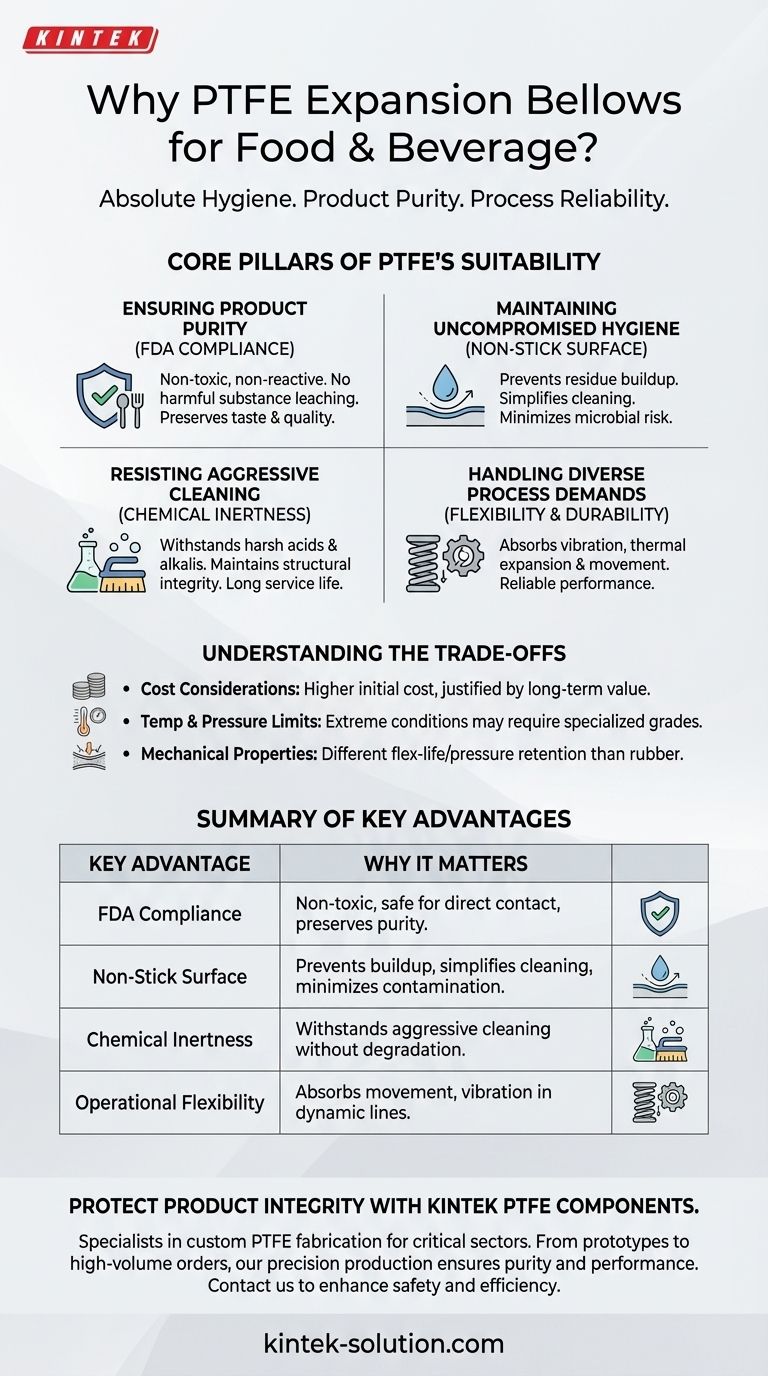

The Core Pillars of PTFE's Suitability

To understand why PTFE is the standard, we must look at how its fundamental characteristics solve the daily challenges of food and beverage processing.

Ensuring Product Purity (FDA Compliance)

The most fundamental requirement is that any material in contact with food must be safe.

PTFE is compliant with FDA standards, meaning it is non-toxic and will not leach harmful substances into the product. This non-reactive nature is crucial for preserving the intended taste, quality, and safety of consumables.

Maintaining Uncompromised Hygiene (Non-Stick Surface)

Cleanliness is paramount in preventing bacterial growth and cross-contamination.

The non-stick surface of PTFE is its most significant hygienic advantage. It drastically reduces the ability of food particles, syrups, or dairy residues to adhere to the bellow's surface, simplifying cleaning cycles and minimizing the risk of microbial colonization.

Resisting Aggressive Cleaning Cycles (Chemical Inertness)

Food processing equipment undergoes frequent and harsh cleaning regimens, often using strong acids and alkalis.

PTFE exhibits exceptional resistance to these aggressive cleaning chemicals. Unlike other materials that might degrade over time, PTFE maintains its structural integrity, ensuring a long service life and preventing material breakdown that could contaminate the production line.

Handling Diverse Process Demands (Flexibility and Durability)

Processing lines are dynamic systems with vibration, thermal expansion, and movement.

Expansion bellows made from PTFE provide the necessary flexibility to absorb these movements without failing. This mechanical durability, combined with its other properties, ensures reliable performance across a wide range of operating conditions.

Understanding the Trade-offs

While PTFE is the superior choice for most food-grade applications, an objective assessment requires acknowledging its operational boundaries.

Cost Considerations

Materials like PTFE often have a higher initial procurement cost compared to standard elastomers like EPDM or silicone. This cost, however, is typically justified by a longer service life, reduced downtime, and lower contamination risk.

Temperature and Pressure Limits

While PTFE has a broad operating temperature range, it is not limitless. Extreme high-temperature applications, particularly those involving high pressure, may require specialized grades of PTFE or alternative materials.

Mechanical Properties

PTFE is a durable plastic, but it is not a true elastomer. It has different flex-life and pressure-retention characteristics than rubber. In high-cycle, high-pressure pulsation applications, system design must account for PTFE's specific mechanical properties.

Making the Right Choice for Your Application

Selecting the right material is a function of your primary operational goal.

- If your primary focus is maximizing food safety and hygiene: PTFE is the unequivocal choice due to its FDA compliance and unparalleled non-stick surface.

- If your primary focus is ensuring long-term operational reliability: PTFE's resistance to harsh cleaning chemicals provides a longer, more predictable service life with less frequent replacement.

- If your primary focus is handling a wide variety of products: The chemical inertness of PTFE makes it suitable for everything from acidic fruit juices to dairy products without risk of reaction or contamination.

Ultimately, choosing PTFE for expansion bellows is an investment in process integrity and product safety.

Summary Table:

| Key Advantage | Why It Matters for Food & Beverage |

|---|---|

| FDA Compliance | Ensures material is non-toxic and safe for direct food contact, preserving product purity. |

| Non-Stick Surface | Prevents residue buildup, simplifies cleaning, and minimizes microbial contamination risk. |

| Chemical Inertness | Withstands aggressive cleaning chemicals (acids, alkalis) without degrading. |

| Operational Flexibility | Absorbs movement, vibration, and thermal expansion in dynamic processing lines. |

Protect your product integrity and streamline your operations with precision-engineered PTFE components from KINTEK.

As specialists in custom PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical need for materials that guarantee purity and performance. Whether you need a prototype or a high-volume order of PTFE seals, liners, labware, or expansion bellows, our commitment to precision production ensures a solution tailored to your exact requirements.

Contact us today to discuss how our PTFE components can enhance the safety and efficiency of your food and beverage processing line.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments