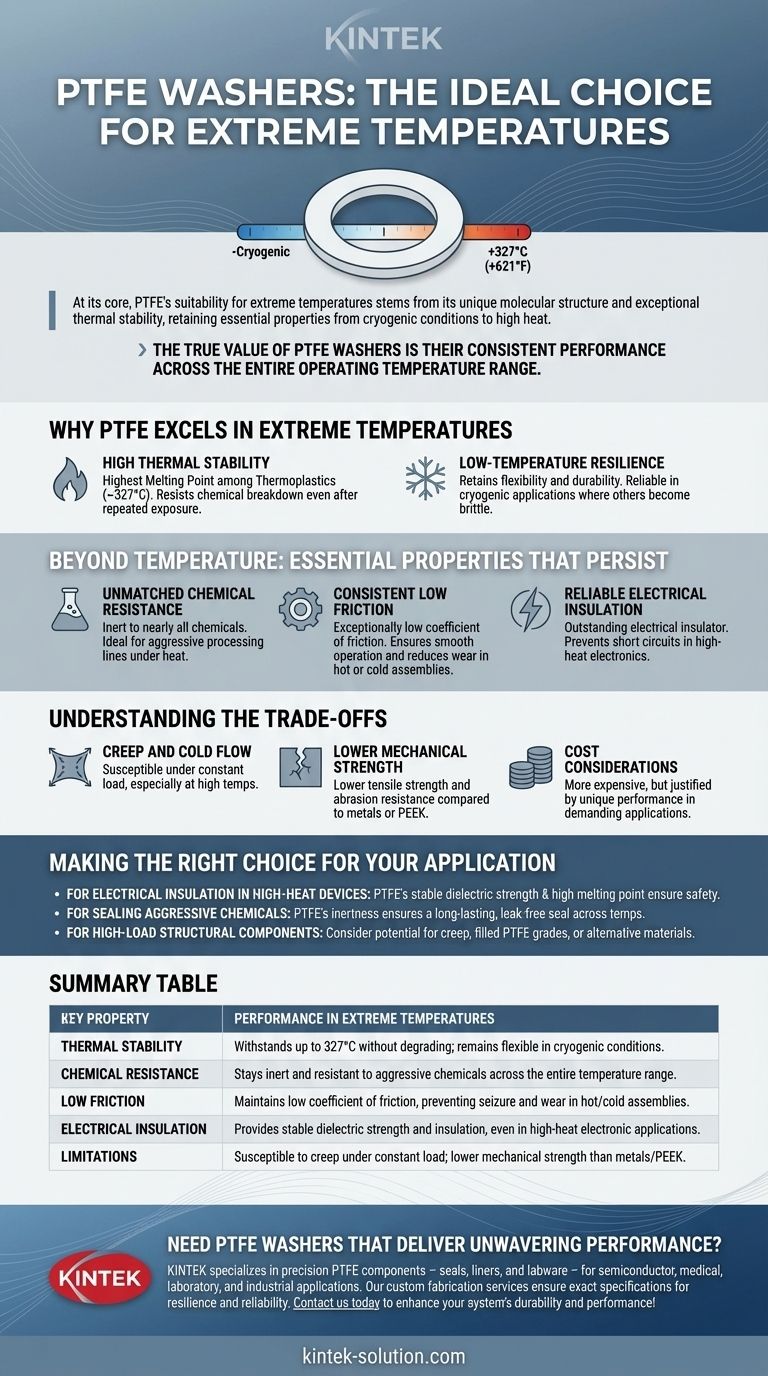

At its core, PTFE's suitability for extreme high and low temperatures stems from its unique molecular structure and exceptional thermal stability. With a melting point around 327°C (621°F), it can withstand significant heat without degrading, while also retaining its essential properties in cryogenic conditions where other materials become brittle.

The true value of PTFE washers in extreme temperatures is not just their survival, but their consistent performance. Key characteristics like chemical resistance, low friction, and electrical insulation remain remarkably stable across its entire wide operating temperature range.

The Foundation: Why PTFE Excels in Extreme Temperatures

The ability of Polytetrafluoroethylene (PTFE) to handle a vast temperature spectrum is not an accident; it's a direct result of its material science. This makes it a default choice for engineers designing systems that will face thermal cycling or operate in consistently harsh environments.

High Thermal Stability

PTFE has one of the highest melting points among thermoplastics, at approximately 327°C (621°F).

More importantly, it exhibits excellent thermal stability, meaning it resists chemical breakdown and degradation even after repeated exposure to high temperatures.

Low-Temperature Resilience

While many polymers become rigid and brittle at very low temperatures, PTFE retains its flexibility and durability.

This makes it a reliable sealing and insulating material for cryogenic applications where other plastics would crack and fail.

Beyond Temperature: Essential Properties That Persist

A material's ability to simply exist at a certain temperature is not enough. For a component like a washer, its functional properties must remain reliable. PTFE excels because its most valuable traits are not compromised by thermal extremes.

Unmatched Chemical Resistance

PTFE is famously inert and resistant to nearly all industrial chemicals and solvents.

This chemical resistance does not diminish at high temperatures, making PTFE washers ideal for sealing flanges in aggressive chemical processing lines that operate under heat.

Consistent Low Friction

PTFE has an exceptionally low coefficient of friction, giving it a "non-stick" quality.

This property is maintained across its temperature range, ensuring smooth operation in mechanical assemblies, preventing seizure of fasteners, and reducing wear between components whether they are hot or cold.

Reliable Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength.

In electronics, where components generate significant heat, PTFE washers prevent short circuits and maintain their insulating properties without failing, ensuring both safety and performance.

Understanding the Trade-offs

While its thermal and chemical properties are elite, no material is perfect. Understanding the limitations of PTFE is critical for proper application design.

Creep and Cold Flow

PTFE is a relatively soft material. Under a constant compressive load (like a tightened bolt), it can slowly deform or "creep," especially as temperatures rise. This can lead to a loss of bolt torque over time.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or metals, PTFE has lower tensile strength and abrasion resistance. It is not suitable for high-load, structural applications on its own.

Cost Considerations

PTFE is more expensive than common polymers like nylon or polyethylene. Its cost is justified by its unique performance profile, making it cost-effective for demanding applications where other materials would fail.

Making the Right Choice for Your Application

Selecting a washer material requires balancing performance needs with physical limitations. PTFE is the superior choice when its specific combination of properties is essential for system reliability.

- If your primary focus is electrical insulation in a high-heat device: PTFE's stable dielectric strength and high melting point make it a definitive choice for safety and reliability.

- If your primary focus is a sealing solution for aggressive chemicals: PTFE's broad chemical inertness ensures a long-lasting, leak-free seal across a wide range of operating temperatures.

- If your primary focus is a high-load structural component under compression: You must account for PTFE's potential to creep or consider a filled grade of PTFE or an entirely different material.

Ultimately, you choose a PTFE washer when you need its key performance characteristics to remain unchanged, regardless of the temperature.

Summary Table:

| Key Property | Performance in Extreme Temperatures |

|---|---|

| Thermal Stability | Withstands temperatures up to 327°C (621°F) without degrading; remains flexible in cryogenic conditions. |

| Chemical Resistance | Stays inert and resistant to aggressive chemicals and solvents across the entire temperature range. |

| Low Friction | Maintains a low coefficient of friction, preventing seizure and wear in hot or cold mechanical assemblies. |

| Electrical Insulation | Provides stable dielectric strength and insulation, even in high-heat electronic applications. |

| Limitations | Susceptible to creep under constant load; lower mechanical strength compared to metals or PEEK. |

Need PTFE washers that deliver unwavering performance in your most demanding thermal environments? At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our custom fabrication services, from prototypes to high-volume orders, ensure you get components that meet exact specifications for temperature resilience, chemical resistance, and reliability. Contact us today to discuss how our PTFE solutions can enhance your system's durability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How are PTFE lip seals used in the aerospace industry? Ensure Reliability in Extreme Conditions

- What are the key advantages of PTFE in medical applications? Unmatched Biocompatibility and Low Friction

- How do spring energized PTFE seals compare to elastomeric seals in dynamic service? Superior Performance in Extreme Conditions

- What are the key properties of PTFE valves? Ensure Purity, Safety, and Reliability in Demanding Processes

- What are common industrial applications of machined Teflon parts? Solve Friction, Chemical & Electrical Challenges

- What are the main applications of rotary shaft seals? From Automotive to Pharma, Ensure Zero Leaks

- What is the alternative to PTFE gaskets that combines its advantages with better sealing properties? Discover Enhanced Sealing Solutions

- What are the different types of PTFE seals and their applications? Match the Right Seal to Your Application