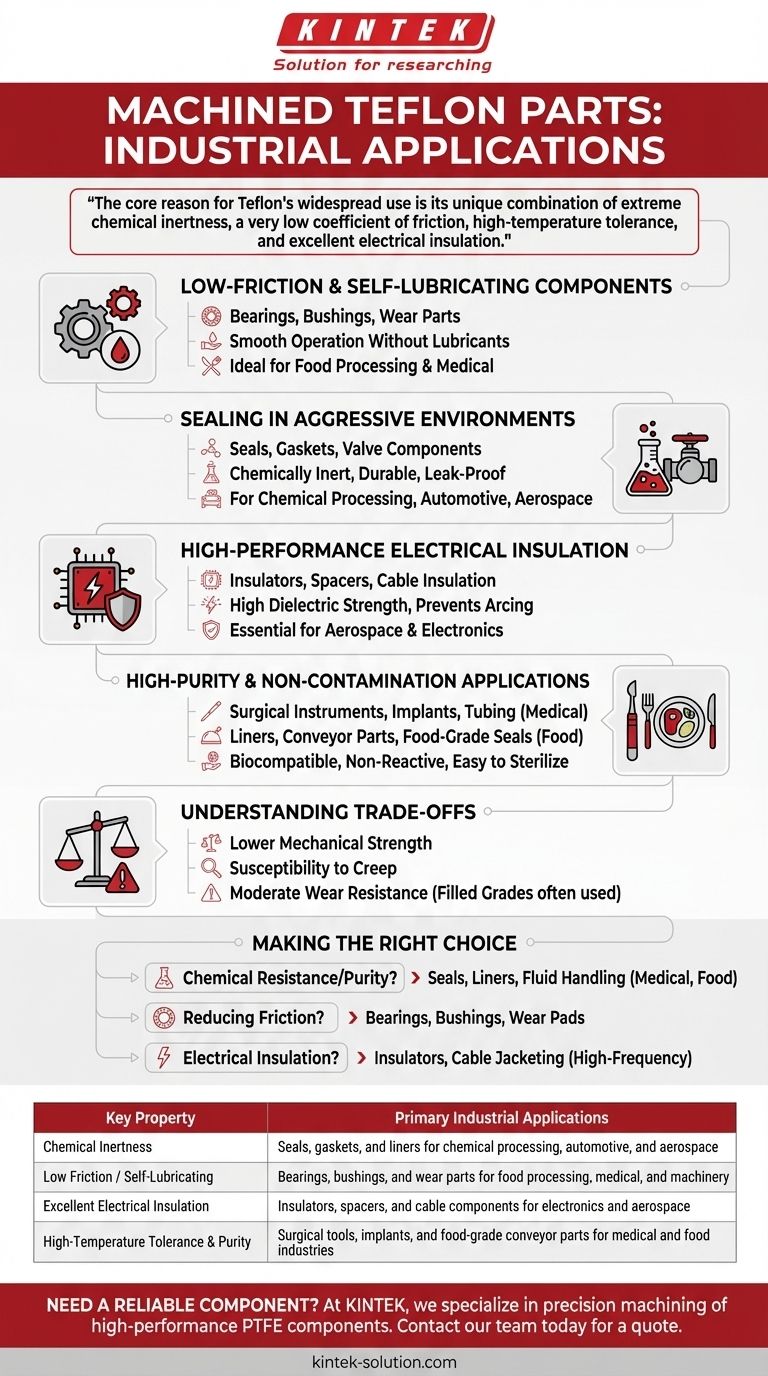

The most common industrial applications for machined Teflon parts are seals, gaskets, bearings, bushings, and electrical insulators. These components are critical across a wide range of demanding sectors, including aerospace, medical, chemical processing, and food production, where standard materials would fail.

The core reason for Teflon's widespread use is not a single feature, but its unique combination of four key properties: extreme chemical inertness, a very low coefficient of friction, high-temperature tolerance, and excellent electrical insulation.

Why Teflon is the Material of Choice

The decision to machine a part from Teflon (PTFE) is almost always driven by a need for performance under conditions that would degrade or destroy other materials. Its value comes from its ability to solve specific engineering challenges related to friction, chemical exposure, temperature, and electricity.

For Low-Friction and Self-Lubricating Components

Machined Teflon is a go-to material for parts where reducing friction is paramount. Its self-lubricating nature means it operates smoothly without external oils or greases.

This makes it ideal for bearings, bushings, and wear parts in machinery. The components can function in environments where lubricants would contaminate the product, such as in food processing or medical equipment.

For Sealing in Aggressive Environments

Teflon is almost completely inert, meaning it does not react with the vast majority of industrial chemicals, acids, and bases. This makes it an essential material for fluid handling and containment.

This property is why it is specified for seals, gaskets, and valve components in the chemical processing, automotive, and aerospace industries. It ensures a durable, leak-proof seal that won't degrade when exposed to corrosive fuels, solvents, or reactants.

For High-Performance Electrical Insulation

Teflon is an exceptional electrical insulator with high dielectric strength. It does not conduct electricity and can withstand high voltages, making it a critical safety and performance component.

This is why it is frequently used for electrical insulators, spacers, and cable insulation, especially in aerospace and electronics. It protects sensitive components and prevents electrical arcing, even in compact and high-power designs.

For High-Purity and Non-Contamination Applications

Because Teflon is biocompatible, non-reactive, and easy to sterilize, it is trusted in industries where purity is non-negotiable.

In the medical field, it is machined into surgical instruments, implants, and tubing. In food processing, its non-stick surface is used for liners, conveyor parts, and seals that comply with food-grade standards.

Understanding the Trade-offs

While Teflon's properties are exceptional, it is not a universal solution. Understanding its limitations is key to using it effectively.

Lower Mechanical Strength

Compared to metals and many engineering plastics, Teflon is a relatively soft material. It has lower tensile strength and is not suitable for high-load structural applications.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, Teflon can be prone to "creep" or cold flow. This means the material can slowly deform over time, which must be accounted for in the design of parts like seals and gaskets.

Moderate Wear Resistance

While Teflon has an extremely low coefficient of friction, its resistance to abrasive wear is only moderate. For high-wear applications, filled grades of Teflon (mixed with glass, carbon, or other materials) are often used to improve durability.

Making the Right Choice for Your Application

Selecting Teflon should be a deliberate choice based on the specific operational demands of the component.

- If your primary focus is chemical resistance or purity: Teflon is the default choice for seals, liners, and fluid-handling components exposed to corrosive media or used in medical and food-grade applications.

- If your primary focus is reducing friction without lubrication: Specify Teflon for bearings, bushings, and wear pads where external lubricants are impractical or would cause contamination.

- If your primary focus is high-performance electrical insulation: Teflon provides a superior solution for insulators and cable jacketing, especially in high-frequency or high-voltage scenarios.

Ultimately, choosing to machine a part from Teflon is an investment in reliability for environments where other materials simply cannot perform.

Summary Table:

| Key Property | Primary Industrial Applications |

|---|---|

| Chemical Inertness | Seals, gaskets, and liners for chemical processing, automotive, and aerospace. |

| Low Friction / Self-Lubricating | Bearings, bushings, and wear parts for food processing, medical, and machinery. |

| Excellent Electrical Insulation | Insulators, spacers, and cable components for electronics and aerospace. |

| High-Temperature Tolerance & Purity | Surgical tools, implants, and food-grade conveyor parts for medical and food industries. |

Need a reliable component for a demanding application?

At KINTEK, we specialize in precision machining of high-performance PTFE components. Whether you require standard parts or custom fabrication—from prototypes to high-volume orders—we deliver solutions that meet the rigorous demands of the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your parts will perform reliably with superior chemical resistance, low friction, and excellent insulation.

Contact our team today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments