The primary types of PTFE seals include gaskets and O-rings for static applications, and lip seals or piston seals for dynamic, moving parts. Specialized designs like backup rings are used to reinforce other seals under high pressure, while spring-energized seals provide a constant sealing force in demanding conditions like extreme temperatures or irregular surfaces.

The key to selecting the right seal is not just choosing the material (PTFE), but matching the seal's mechanical design to the specific demands of your application—whether it's static, rotating, high-pressure, or subject to extreme temperatures.

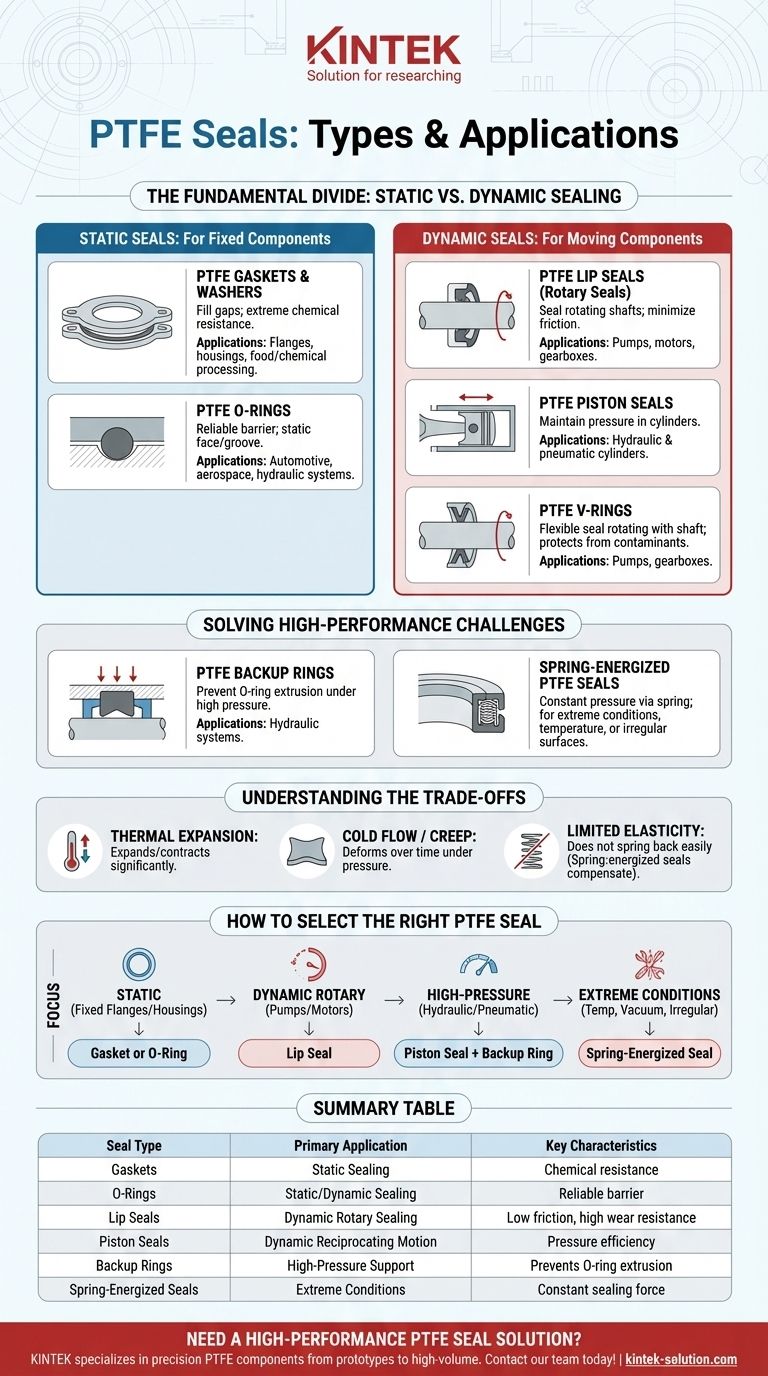

The Fundamental Divide: Static vs. Dynamic Sealing

The first step in choosing a seal is to identify the type of motion involved. Seals are designed to function in either static (stationary) or dynamic (moving) environments.

Static Seals: For Fixed Components

Static seals are used to prevent leakage between two surfaces that do not move relative to each other.

PTFE Gaskets and Washers These are flat seals designed to fill the gap between mating surfaces, such as pipe flanges or machine housings. They are valued for their extreme chemical resistance in industries like chemical and food processing.

PTFE O-Rings While often used in dynamic applications, O-rings provide excellent sealing in static face or groove applications. They create a reliable barrier in automotive, aerospace, and hydraulic systems where components are fixed together.

Mastering Motion: Seals for Dynamic Applications

Dynamic seals are engineered to maintain a seal between components that are in motion, such as a rotating shaft or a reciprocating piston.

PTFE Lip Seals (Rotary Seals)

Also known as rotary shaft seals, these are essential for sealing rotating shafts in equipment like pumps, motors, and gearboxes. Their design minimizes friction and wear, which is critical for efficiency and longevity.

PTFE Piston Seals

These high-performance seals are used in hydraulic and pneumatic cylinders. They seal the gap between the piston and the cylinder wall, ensuring that pressure is maintained efficiently during reciprocating (back-and-forth) motion.

PTFE V-Rings

V-rings are flexible seals that fit directly on a shaft and rotate with it. Their lip seals against a counter-face, effectively protecting bearings and other components from contaminants in pumps and gearboxes.

Solving High-Performance Challenges

For applications involving extreme pressure, temperature, or surface imperfections, standard seal designs may not be sufficient. Specialized PTFE seals address these challenges directly.

PTFE Backup Rings

Under high pressure, a standard O-ring can be forced into the gap between metal components, a failure known as extrusion. A PTFE backup ring is a rigid, non-sealing ring installed next to the O-ring to prevent this deformation.

Spring-Energized PTFE Seals

This advanced design features a PTFE jacket and an internal activating spring. The spring provides a constant, uniform pressure against the sealing surface, ensuring a tight seal even in situations with low pressure, cryogenic temperatures, or slightly irregular hardware surfaces.

Understanding the Trade-offs

While PTFE is an exceptional material, its properties create specific design considerations that are critical for success.

Cold Flow or "Creep"

Under sustained pressure and temperature, PTFE can slowly deform over time. This property, known as creep, must be accounted for in the design of the seal gland to ensure long-term performance.

Limited Elasticity

Unlike rubber elastomers, PTFE is not very elastic and does not "spring back" into shape easily. This is precisely why spring-energized seals were developed—the internal spring compensates for PTFE's low elasticity, maintaining constant contact.

Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. This difference in thermal expansion must be considered when designing the hardware to ensure a proper seal is maintained across the full operating temperature range.

How to Select the Right PTFE Seal

Your choice should be dictated by the mechanical requirements of the system.

- If your primary focus is a static seal between fixed flanges or housings: A PTFE gasket or O-ring is your most direct and reliable solution.

- If your primary focus is sealing a rotating shaft in a pump or motor: A PTFE lip seal is specifically engineered for this dynamic rotary motion.

- If your primary focus is a high-pressure hydraulic or pneumatic system: Use a PTFE piston seal for reciprocating motion and add a PTFE backup ring to support O-rings.

- If your primary focus is performance in extreme temperatures, vacuum, or on irregular surfaces: A spring-energized PTFE seal provides the consistent force needed where other seals might fail.

Ultimately, choosing the correct PTFE seal means matching its physical form to the functional challenge at hand.

Summary Table:

| Seal Type | Primary Application | Key Characteristics |

|---|---|---|

| PTFE Gaskets | Static Sealing (flanges, housings) | Chemical resistance, ideal for food/chemical processing |

| PTFE O-Rings | Static/Dynamic Sealing | Reliable barrier for automotive, aerospace, hydraulic systems |

| PTFE Lip Seals | Dynamic Rotary Sealing (pumps, motors) | Low friction, high wear resistance for rotating shafts |

| PTFE Piston Seals | Dynamic Reciprocating Motion (hydraulic/pneumatic cylinders) | Maintains pressure efficiency in back-and-forth motion |

| PTFE Backup Rings | High-Pressure Support | Prevents O-ring extrusion under extreme pressure |

| Spring-Energized PTFE Seals | Extreme Conditions (temperature, vacuum, irregular surfaces) | Internal spring ensures constant sealing force |

Need a High-Performance PTFE Seal Solution?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard static gasket or a custom spring-energized seal for extreme conditions, we provide expert fabrication from prototypes to high-volume orders.

Let us help you select or design the perfect seal for your application. Contact our team today to discuss your requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications