In the aerospace industry, PTFE lip seals are critical components used in high-performance systems where extreme conditions are the norm. They are engineered to function reliably in applications ranging from jet engine gearboxes and flight control actuators to auxiliary power units (APUs) and fuel pumps, where failure could have catastrophic consequences.

The core reason PTFE is the material of choice for aerospace seals is its unique ability to maintain sealing integrity across an extreme range of temperatures, pressures, and chemical environments. Its low-friction nature is essential for the high-speed, high-reliability demands of modern aircraft.

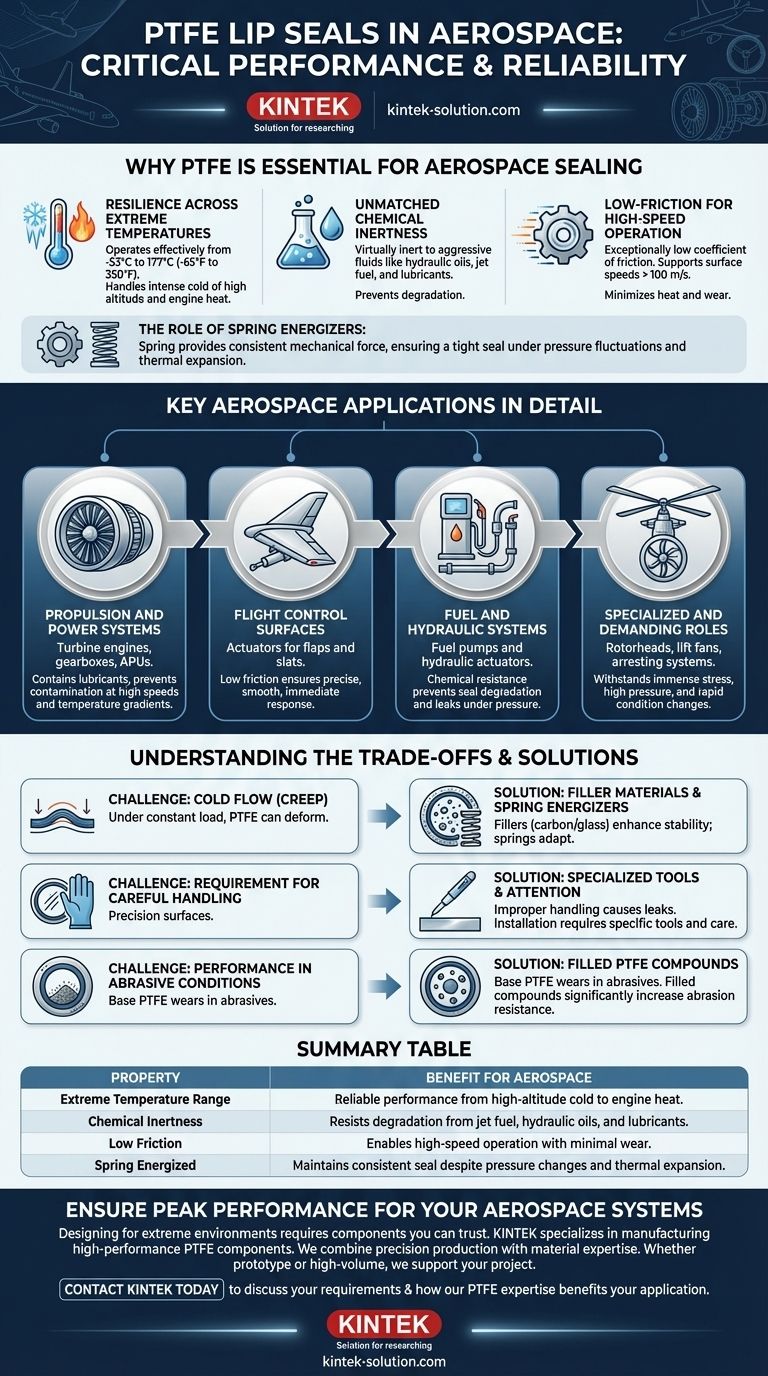

Why PTFE is Essential for Aerospace Sealing

The operational environment of an aircraft—from ground level to high altitude and back—imposes extreme demands that most materials cannot meet. PTFE (Polytetrafluoroethylene) possesses a combination of properties that makes it uniquely suited for these challenges.

Resilience Across Extreme Temperatures

PTFE seals operate effectively in a vast temperature window, typically from -53°C to 177°C (-65°F to 350°F).

This allows them to function flawlessly during the intense cold of high-altitude flight and the significant friction-generated heat found in engines and actuators.

Unmatched Chemical Inertness

Aircraft rely on aggressive fluids like hydraulic oils, jet fuel, and lubricants.

PTFE is virtually inert to these chemicals, ensuring the seal does not swell, degrade, or fail over time due to chemical attack. This stability is fundamental to long-term system reliability.

Low-Friction for High-Speed Operation

Many aerospace applications involve high-speed rotation or reciprocation, with surface speeds reaching over 100 m/s in some cases.

PTFE's exceptionally low coefficient of friction minimizes heat generation, prevents stick-slip movement in actuators, and reduces wear, ensuring smooth and predictable performance of critical systems.

The Role of Spring Energizers

In many aerospace designs, the PTFE lip is energized with a metallic spring.

This spring provides a consistent mechanical force on the sealing lip, ensuring a tight seal even at very low pressures or when temperature fluctuations cause hardware components to expand or contract.

Key Aerospace Applications in Detail

PTFE lip seals are not used for generic purposes; they are specified for systems where performance and reliability are paramount.

Propulsion and Power Systems

Applications like turbine engines, external gearboxes, APUs, starters, and alternators involve high rotational speeds and significant temperature gradients.

PTFE seals are essential for containing lubricants and preventing contamination in these dynamic environments.

Flight Control Surfaces

The actuators for wing flaps, slats, and other control surfaces require seals that provide low friction for precise, immediate response.

PTFE lip seals ensure smooth actuation without the jerky movements that could compromise flight control.

Fuel and Hydraulic Systems

Components such as fuel pumps and hydraulic actuators are constantly exposed to aggressive fluids under pressure.

The chemical resistance of PTFE prevents seal degradation, ensuring these systems remain leak-free and operate at specified pressures.

Specialized and Demanding Roles

PTFE seals are also found in highly specialized equipment like rotorheads, lift fans for vertical lift aircraft, and aircraft arresting systems.

In these roles, they must withstand immense stress, high pressures, and rapid changes in operating conditions, proving their exceptional toughness and durability.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Understanding their limitations is key to proper application.

Potential for Cold Flow (Creep)

Under a constant load, especially at elevated temperatures, PTFE can slowly deform or "creep."

Designers mitigate this by using filler materials (like carbon or glass) to enhance dimensional stability and by employing spring energizers that adapt to minor changes in seal shape.

Requirement for Careful Handling

The sealing surfaces of PTFE are precision-engineered. Scratches or imperfections from improper handling can create leak paths.

Installation requires specialized tools and careful attention to surface finishes to ensure a reliable seal is established.

Performance in Abrasive Conditions

While tough, base PTFE can be susceptible to wear from abrasive particles.

For environments where abrasive contaminants are a concern, filled PTFE compounds are used to significantly increase the seal's abrasion resistance.

Making the Right Choice for Your Application

The specific demands of the system dictate the optimal PTFE seal configuration.

- If your primary focus is high-speed rotation (e.g., gearboxes, turbines): A low-friction PTFE compound is essential to minimize heat generation and extend the operational life of the seal and surrounding components.

- If your primary focus is sealing across extreme temperature cycles (e.g., engine components): A spring-energized design is non-negotiable, as it maintains a consistent sealing force as metal hardware expands and contracts.

- If your primary focus is compatibility with aggressive fluids (e.g., fuel and hydraulic systems): Choose a PTFE compound specifically tested for inertness against the target fluids to prevent degradation and ensure system integrity.

Ultimately, selecting the correct PTFE seal design is a critical step in ensuring the safety and operational reliability of any aerospace system.

Summary Table:

| Property | Benefit for Aerospace |

|---|---|

| Extreme Temperature Range (-53°C to 177°C) | Reliable performance from high-altitude cold to engine heat. |

| Chemical Inertness | Resists degradation from jet fuel, hydraulic oils, and lubricants. |

| Low Friction | Enables high-speed operation in gearboxes and actuators with minimal wear. |

| Spring Energized | Maintains a consistent seal despite pressure changes and thermal expansion. |

Ensure Peak Performance for Your Aerospace Systems

Designing for extreme environments requires components you can trust. The right PTFE seal is critical for the reliability of your propulsion systems, flight controls, and hydraulic units.

KINTEK specializes in manufacturing high-performance PTFE components—including custom lip seals, liners, and labware—for the semiconductor, medical, laboratory, and specialized industrial sectors. We combine precision production with extensive material expertise to deliver solutions that meet the stringent demands of the aerospace industry.

Whether you need a custom prototype or are scaling to high-volume production, we are here to support your project.

Contact KINTEK today to discuss your specific requirements and how our PTFE expertise can benefit your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What types of PTFE tri clamp gaskets are available? Choose the Right Seal for Your System

- What are common applications for unfilled PTFE sheets? Leverage Chemical Inertness & Purity

- Why are PTFE seats preferred in electric actuated butterfly valves? Enhance Valve Performance and Actuator Lifespan

- What precautions should be taken when using PTFE gaskets in high-pressure applications? Ensure a Reliable, Leak-Free Seal

- What temperature range can PTFE O-rings withstand? Unlock Extreme Thermal Performance from -200°C to 260°C

- Are PTFE O-rings safe for medical applications? Ensuring Biocompatibility for Critical Devices

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How is PTFE typically processed in manufacturing? A Guide to Molding, Sintering & Machining